A kind of high temperature resistant acrylate rubber and preparation method thereof

An acrylate and high-temperature-resistant technology, which is applied in the field of acrylate rubber, can solve the problems that the high-temperature resistance of acrylate rubber is difficult to meet the requirements, so as to improve resin dispersion and contact stability, increase cross-linking density, and improve heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of high-temperature-resistant acrylate rubber, the specific method is: step (1): take 25 parts by weight of solvent into the reactor, heat to 100 ° C, and then add 40 parts by weight of hard monomer methyl methacrylate, soft sheet 12 parts by weight of n-butyl acrylate, 3 parts by weight of hydroxyethyl acrylate, 3 parts by weight of epoxy acrylate, 6 parts by weight of benzyl methacrylate, 3 parts by weight of 2-hydroxyethyl methacrylate phosphate, In the core-shell microspheres, 4 parts by weight of each of the three types of microspheres with silica as the shell and lead-zinc-tin as the core and 1.2 parts by weight of the initiator are mixed evenly, and are added dropwise into the reactor at a uniform speed. The dropping process is completed in 1.5 hours. , continue to react for 1h; Step (2): 3 parts by weight of hydroxyethyl acrylate, 3 parts by weight of epoxy acrylate, 6 parts by weight of benzyl methacrylate, 3 parts by weight of 2-hydroxyet...

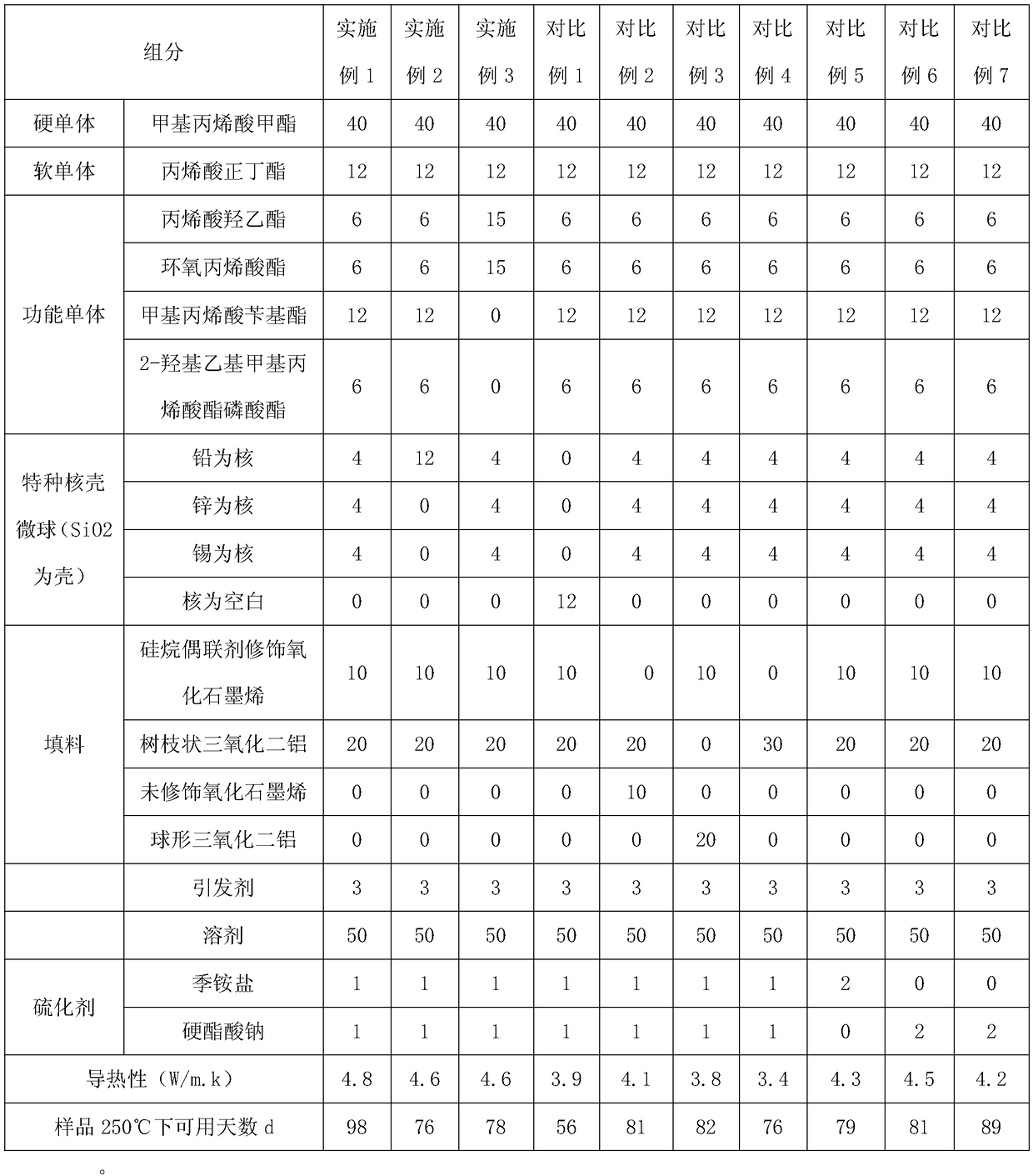

Embodiment 2-3 and comparative example 1-7

[0022] The preparation methods of Examples 2-3 and Comparative Examples 1-6 are the same as those of Example 1, the only difference being the difference in components and dosage, see the table below for details. In the preparation method of Comparative Example 7, the filler and the core-shell microspheres were added at the same time, and the components and dosage were the same as in Example 1.

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com