Double-layer structural bonding layer on the surface of single crystal alloy and its preparation method

A double-layer structure and bonding layer technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the complex composition and performance regulation of bonding layer, high cost, and the influence of the interface bonding performance of the barrier diffusion layer. and other problems, to achieve good high temperature oxidation resistance, low cost, and improve the effect of high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

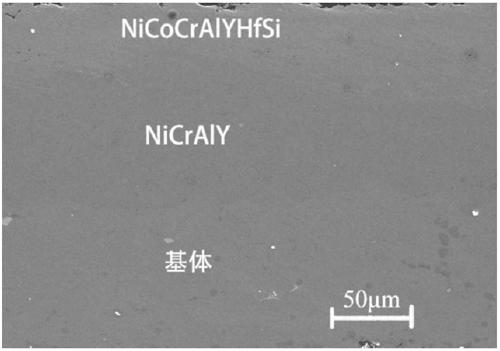

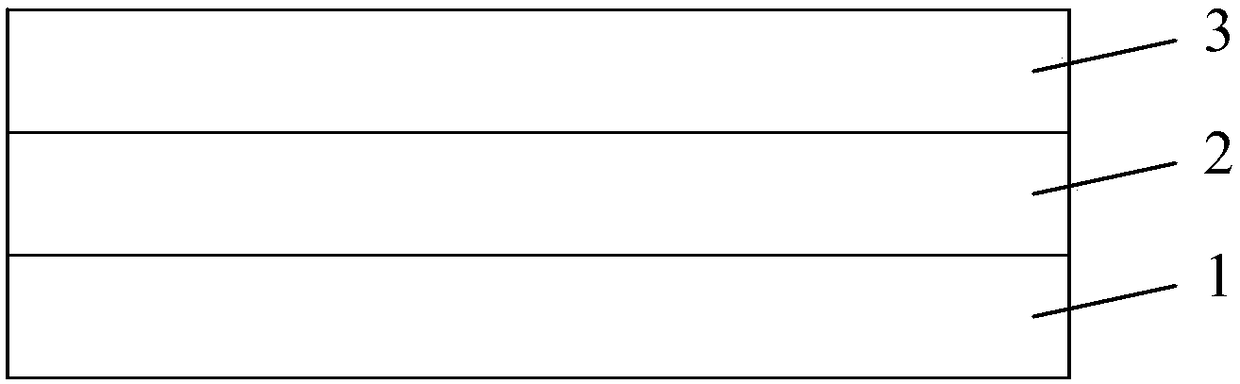

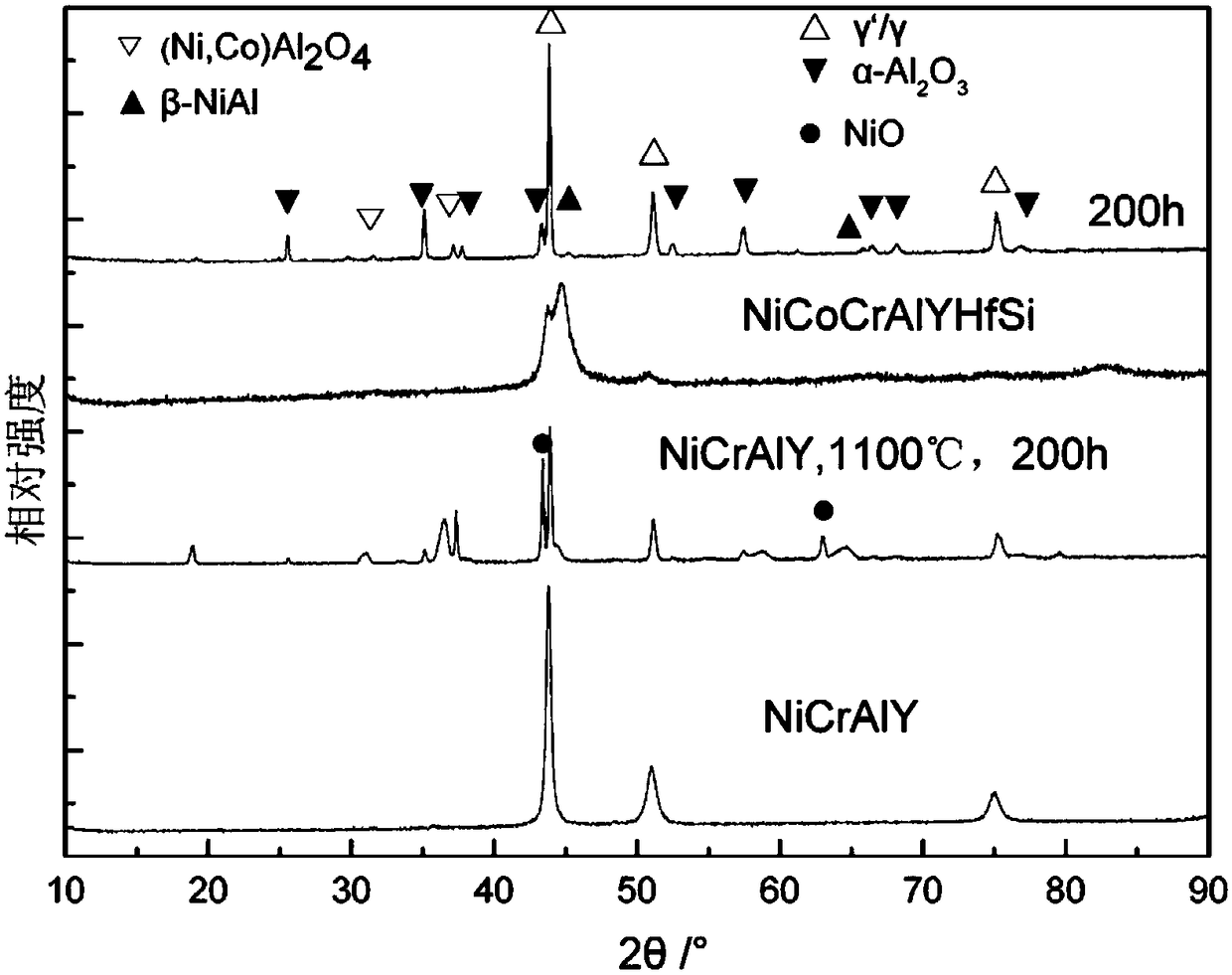

[0071] Example 1: Preparation of a double-layer structural bonding layer on the surface of DD6 single crystal alloy

[0072] Step 1: Prepare the DD6 single crystal alloy matrix material, clean it with anhydrous acetone, use a suction sandblasting machine to perform sandblasting roughening on the surface to be sprayed under the pressure of 0.1Mpa sandblasting gas, and then use compressed air to blow off the residue on the surface Sand and clean it again with anhydrous acetone, install the base on the tooling, and wait for spraying.

[0073] The second step: the dry Ni26Cr4Al0.4Y (abbreviation here means: "the total weight is 100%, 0.4% of Y, 4% of Al, 26% of Cr, and the rest is Ni", and the same abbreviation is adopted in the following text way, no more details) and Ni20Co18Cr12Al0.7Y0.5Hf0.1Si bonding layer powder were put into the powder feeder.

[0074] Step 3: Turn on the oxygen-kerosene supersonic flame spraying equipment, and the spraying process parameters are:

[0075...

Embodiment 2

[0084] Example 2: Preparation of a double-layer structural bonding layer on the surface of IC10 single crystal alloy

[0085] Step 1: Prepare the IC10 single crystal alloy substrate material, clean it with anhydrous acetone, use a suction sandblasting machine to perform sandblasting roughening on the surface to be sprayed under the pressure of 0.15Mpa sandblasting gas, and then use compressed air to blow off the residue on the surface Sand and clean it again with anhydrous acetone, install the base on the tooling, and wait for spraying.

[0086] The second step: Put the dried Ni24Cr6Al0.7Y and Ni24Co15Cr13Al0.1Y0.5Hf0.5Si bonding layer powder into the powder feeder respectively.

[0087] Step 3: Turn on the oxygen-kerosene supersonic flame spraying equipment, and the spraying process parameters are:

[0088] Oxygen flow: 45m 3 / h;

[0089] Kerosene flow: 20m 3 / h;

[0090] Carrier gas flow: 0.8m 3 / h;

[0091] Powder feeding volume: 80g / min;

[0092] Spray gun swing ra...

Embodiment 3

[0097] Example 3: Preparation of a double-layer structural bonding layer on the surface of IC10 single crystal alloy

[0098] Step 1: Prepare the IC10 single crystal alloy substrate material, clean it with anhydrous acetone, use a suction sandblasting machine to perform sandblasting roughening on the surface to be sprayed under the pressure of 0.15Mpa sandblasting gas, and then use compressed air to blow off the residue on the surface Sand and clean it again with anhydrous acetone, install the base on the tooling, and wait for spraying.

[0099] The second step: Put the dried Ni25Cr5Al0.6Y and Ni22Co16Cr11Al1Y0.1Hf0.5Si bonding layer powders into the powder feeder respectively.

[0100] Step 3: Turn on the oxygen-kerosene supersonic flame spraying equipment, and the spraying process parameters are:

[0101] Oxygen flow: 40m 3 / h;

[0102] Kerosene flow: 17m 3 / h;

[0103] Carrier gas flow: 0.5m 3 / h;

[0104] Powder feeding volume: 60g / min;

[0105] Spray gun swing spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com