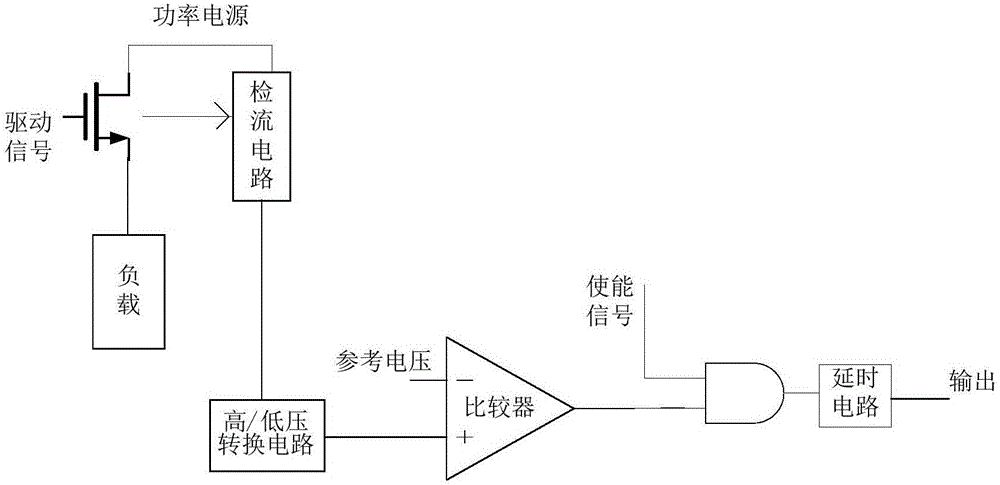

Simplified over-current detection circuit for high-side power tube

A high-end power tube, over-current detection technology, applied in the measurement of electrical variables, measurement of current/voltage, measurement devices, etc., can solve the problems of occupying a lot of chip area, poor accuracy, breakdown damage of high and low voltage circuits, etc. The effect of small area, chip cost saving, and convenient layout layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

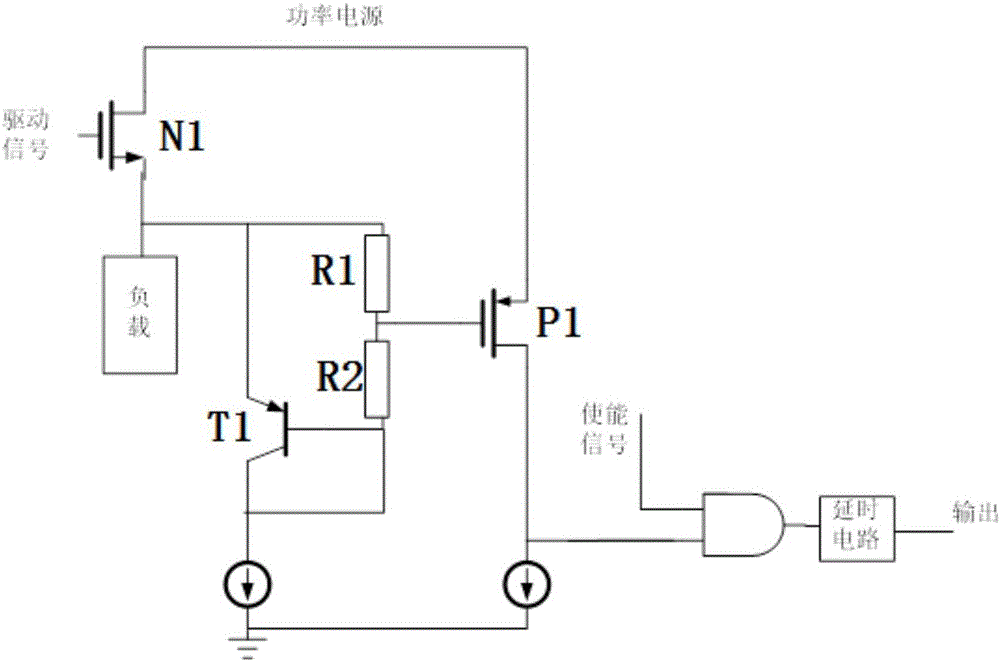

[0021] Such as figure 2 As shown, when the high-end power NMOS transistor N1 is normally turned on, the driving signal is generally higher than the power supply, the high-end power NMOS transistor N1 is in the linear region, and the conduction voltage drop is very small. , not enough to turn on the right switch tube P1. As the current flowing through the load increases, the drain-source voltage drop of the power transistor N1 increases, and the source terminal voltage decreases. When the load current value reaches a certain value, the source terminal voltage is divided by the resistor (the first The resistance ratio between the resistor and the second resistor is adjustable), which can make the right switch tube P1 turn on, the current flowing through the P1 tube is greater than the current provided by the current source, and output a high level to the AND gate. The other input enable signal of the AND gate is synchronized with the drive signal of the power transistor. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com