High temperature-resistant cable based on rock wool and preparation method thereof

A high temperature, cable technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve problems such as negative effects on cable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

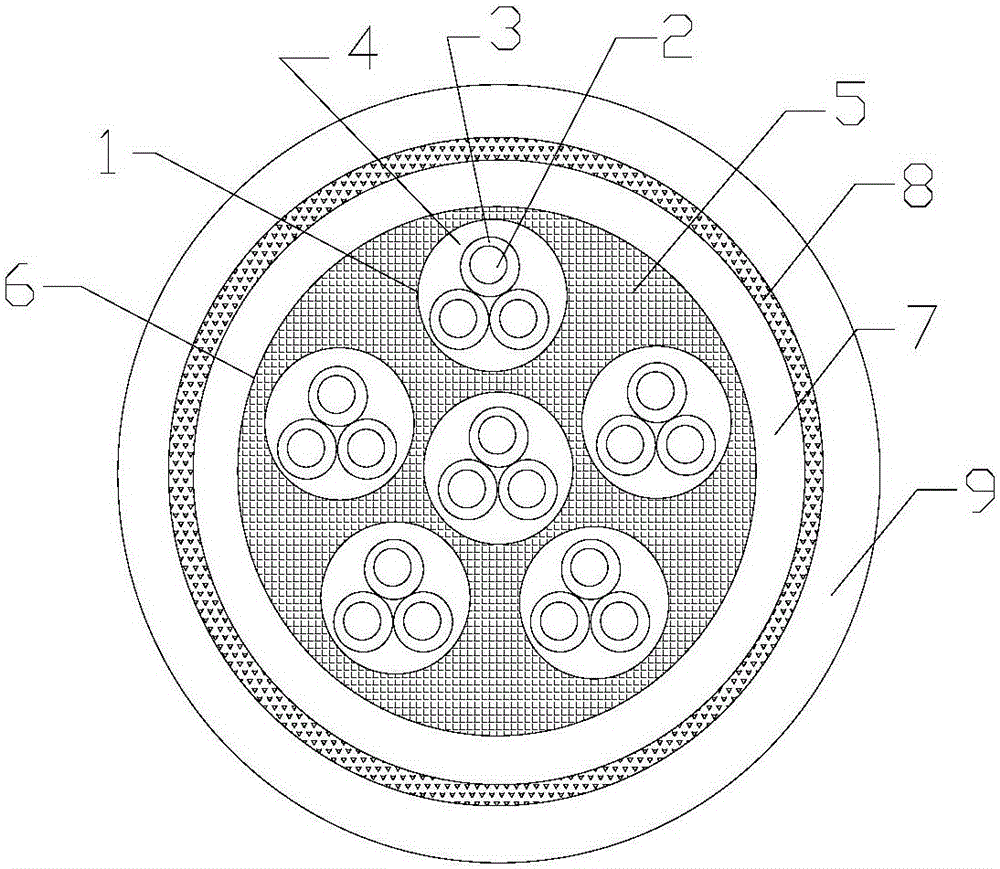

[0036] The present invention also provides a method for preparing the above-mentioned rock wool-based high temperature resistant cable, the preparation method comprising:

[0037] 1) Twisting the multi-strand wire core unit 1 with each other, then putting the silver-plated aramid wire braid 6 on the outside of the multi-strand wire core unit 1, and then filling the silver-plated aramid wire braid 6 with rock wool 5 internal;

[0038] 2) Extrude the acrylonitrile-butadiene-acrylate copolymer on the outside of the silver-plated aramid wire braid 6 to form the first insulating layer 7, and then embed nano-zirconium carbide on the surface of the first insulating layer 7 A critical layer 8 is formed, and then ethylene-tetrafluoroethylene copolymer is extruded on the outside of the first insulating layer 7 to form a second insulating layer 9 to obtain a rock wool-based high temperature resistant cable.

[0039] In the preparation method of the present invention, the silver-plated a...

preparation example 1

[0043] Aramid filaments with a diameter of 0.10 mm are soaked in 60% by weight acid solution (hydrochloric acid solution), then taken out and plated with a silver layer (the thickness of the silver-plated layer is 1.5 μm) on the outer surface of the aramid filaments to produce The silver-plated aramid yarn is obtained, and then the silver-plated aramid yarn is braided into a silver-plated aramid yarn braiding sheath 6 (with a diameter of 0.88 mm).

Embodiment 1

[0045] 1) Twisting multiple strands of silver-plated copper wires 2 (with a diameter of 0.07 mm and a thickness of the silver-plated layer 3 of 0.7 μm), and then extruding polystyrene onto the outside of the multiple strands of silver-plated copper wires 2 to form a protective layer 4 (diameter is 0.25mm) to make the core unit;

[0046] 2) Twisting the multi-strand wire core units with each other, then putting the silver-plated aramid wire braid on the outside of the multi-strand wire core unit, and then filling the inside of the silver-plated aramid wire braid (with silver-plated The area of the cross section of the aramid yarn braid 6 is a benchmark, and the area occupied by the rock wool 5 in the cross section of the silver-plated aramid yarn braid 6 is 40%);

[0047] 3) Extrude acrylonitrile-butadiene-acrylate copolymer on the outside of the silver-plated aramid wire braid to form the first insulating layer 7 (thickness is 0.18mm), and then embed nano-zirconium carbide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com