Sintering clamp and sintering method for multiple tube cores of semiconductor laser in independent pressure-applying manner

A technology of pressure sintering and sintering method, which is applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of high manufacturing cost, damage, difficulty in processing and assembling precision parts, etc., and achieves high production efficiency, convenient operation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

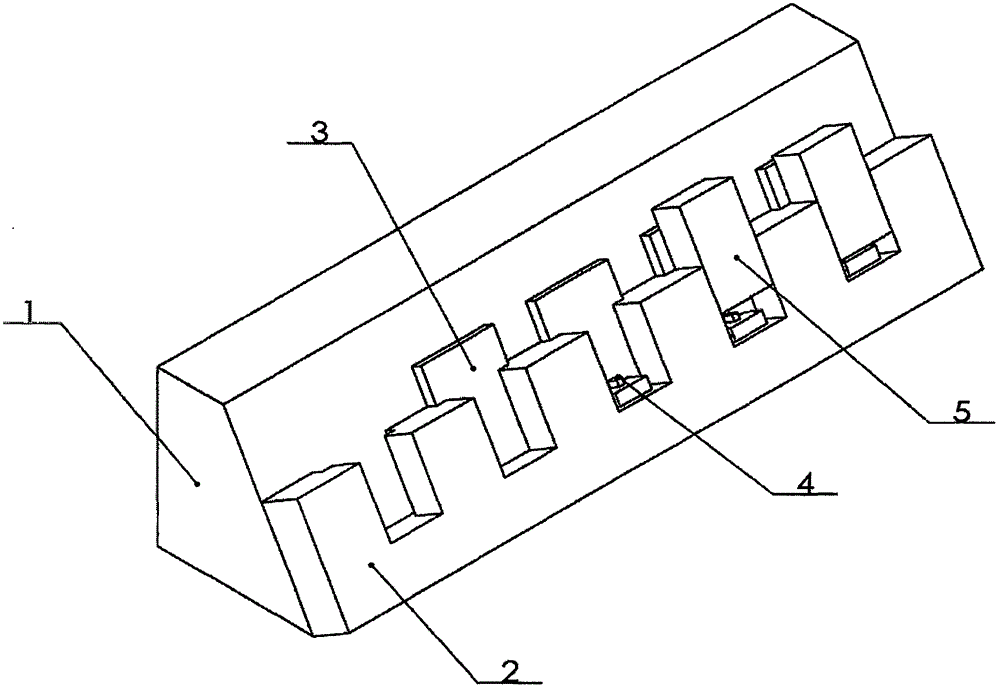

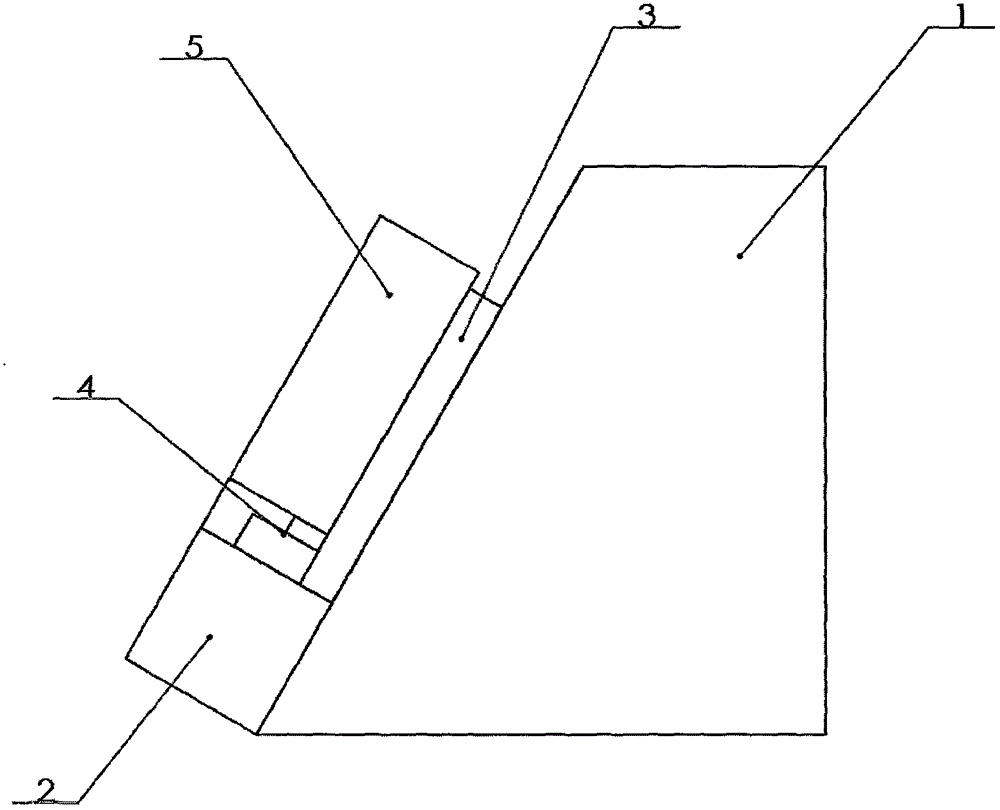

[0026] Please see attached figure 1 and attached figure 2 As shown, a semiconductor laser multi-die pressure sintering fixture includes a base 1, a fixed block 2, a block 3 and a pressing block 5, the longitudinal section of the base 1 is a trapezoidal structure, and the fixed block 2 It is fixed on the slope surface of the base 1 by threading or welding; more than 2 grooves can be opened on the fixed block 2, and each groove is in contact with the slope surface of the base 1 And a card slot is provided inside, and the blocking piece 3 is fitted in the groove along the slope surface of the base 1, and is fixed by the card slot, and each of the grooves corresponds to One of the briquetting blocks 5 .

[0027] The longitudinal section of the base 1 is a right-angled trapezoidal structure, and the fixing block 2 is perpendicular to the slope surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com