Special water curtain type solidification granulation cylinder device for lysozyme dimer

A technology of lysozyme dimer and cylinder device, which is applied in the direction of liquid separation into bead droplets and granulation, can solve the problems of lysozyme dimer particles being too small, not easy to capture, and requiring high dispersion of droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

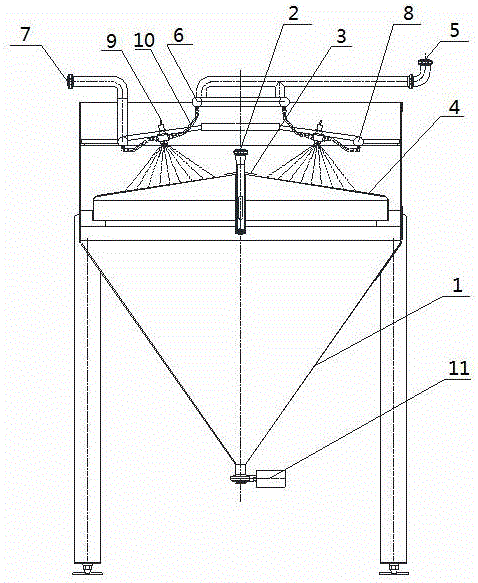

[0018] In this example, see figure 1 , a special water curtain solidification granulation tank device for lysozyme dimer, which is mainly composed of a granulation tank body 1 with a small cone angle cylinder bottom, an umbrella-shaped fluid device, an atomization device, and a control system. A closed chamber is formed inside the cylinder body 1, four cylinder legs with adjustable length and variable inclination are installed outside the granulation cylinder body 1, and the four adjustable cylinder legs are evenly distributed on the granulation cylinder body 1 At the side position, all the corners of the inner surface of the inner wall of the granulation cylinder body 1 adopt a circular arc transition smooth surface structure, and an atomization device is installed on the upper part of the granulation cylinder body 1. The atomization device is mainly composed of lysozyme dimer Prepared liquid inlet 5, prepared liquid distribution pipe 6, compressed air inlet 7, gas distributi...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, especially in that:

[0028] In this embodiment, the calcium chloride umbrella nozzle 3 is an adjustable calcium chloride umbrella nozzle, which can form uniform and continuous umbrella-shaped liquid flow layers of different thicknesses, and the control system automatically adjusts the calcium chloride umbrella nozzle 3. Injection parameters, by controlling the injection flow and injection velocity of the calcium chloride solution, the thickness and uniformity of the uniform and continuous umbrella-shaped liquid flow layer formed on the umbrella-shaped molding disc 4 are controlled to more effectively ensure the dimerization of lysozyme in turn. The body was successfully granulated into microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com