Gasoline car particle capturing catalyst and preparation method thereof

A particle capture and catalyst technology, which is applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of incomplete catalyst treatment, etc., to ensure the ability to resist high temperature aging and improve the ability , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

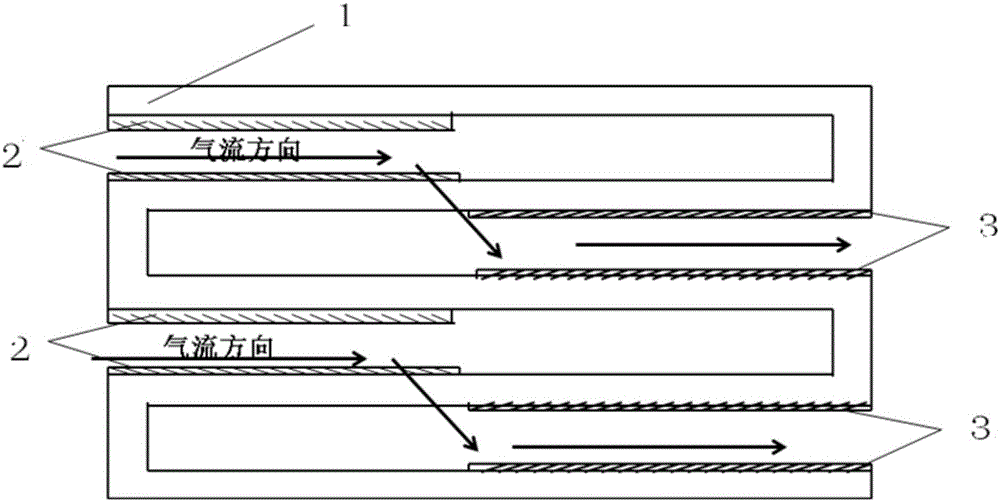

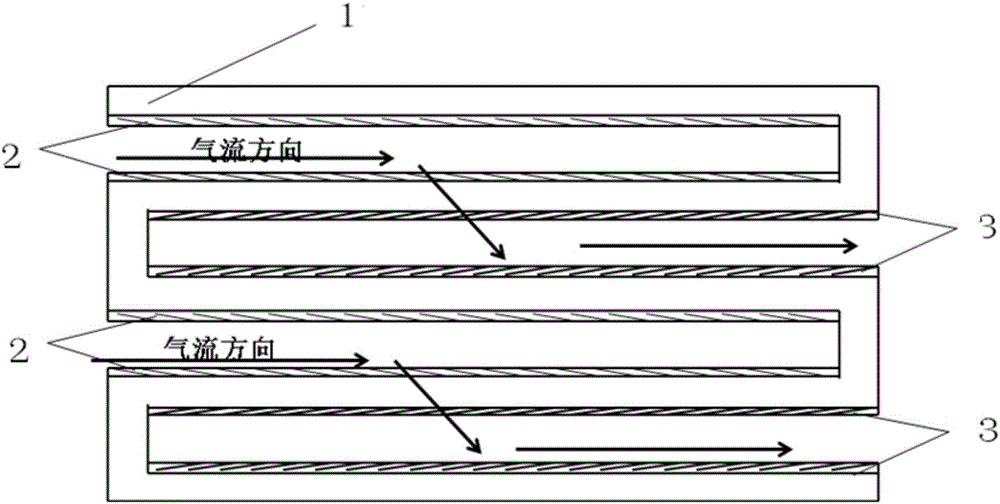

Image

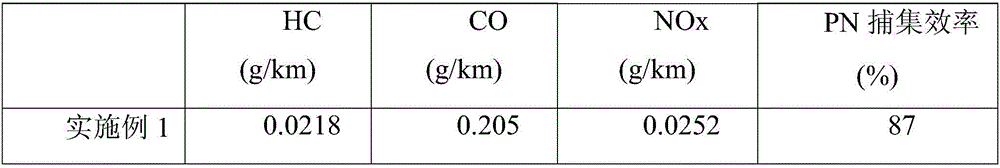

Examples

Embodiment 2

[0033] A particle trapping catalyst for gasoline vehicles, using a wall-flow honeycomb carrier with a specification of Ф118.4mm×119mm, a pore density of 300cpsi, a pore wall thickness of 12mil, a porosity of 65%, an average pore diameter of 20um, and a volume of 1.31L; One end of the first coating is coated with the first coating, the coating height of the first coating is 50% of the height of the carrier, the coating amount is 60g / L, and the loading amount of Rh in the first coating is 3g / ft 3 .

[0034] Coat the other end of the carrier with a second coating, the coating height in the second coating is 50% of the height of the carrier, the coating amount is 60g / L, and the loading amount of noble metal Pd in the second coating is 16g / ft 3 , the loading of precious metal Rh is 1g / ft 3 .

[0035] The preparation method is as follows:

[0036]Add 1500g of cerium-zirconium composite oxide and activated alumina to 6000g of deionized water in turn to prepare a suspension, wher...

Embodiment 3

[0040] A particle trapping catalyst for gasoline vehicles, using a wall-flow honeycomb carrier with a specification of Ф118.4mm×119mm, a pore density of 300cpsi, a pore wall thickness of 12mil, a porosity of 65%, an average pore diameter of 20um, and a volume of 1.31L; One end is first coated with the first coating, the coating height of the first coating is 100% of the height of the carrier, the coating amount is 60g / L, and the loading amount of precious metal Rh in the first coating is 3g / ft 3 .

[0041] Coat the other end of the carrier with a second coating, the coating height of the second coating is 100%, the coating amount is 60g / L, and the loading amount of noble metal Pd in the second coating is 16g / ft 3 , the loading of precious metal Rh is 1g / ft 3 .

[0042] The preparation method is as follows:

[0043] Add 1500g of cerium-zirconium composite oxide and activated alumina to 6000g of deionized water in turn to prepare a suspension, wherein the mass ratio of ceri...

Embodiment 4

[0047] A particle trapping catalyst for gasoline vehicles, using a wall-flow honeycomb carrier with a specification of Ф118.4mm×119mm, a pore density of 300cpsi, a pore wall thickness of 12mil, a porosity of 65%, an average pore diameter of 20um, and a volume of 1.31L; One end of the first coating is coated with the first coating, the coating height of the first coating is 100% of the height of the carrier, the coating amount is 80g / L, and the loading amount of the precious metal Rh in the first coating is 3.6g / ft 3 .

[0048] Coat the other end of the carrier with a second coating, the coating height of the second coating is 100% of the height of the carrier, the coating amount is 80g / L, and the loading amount of noble metal Pd in the second coating is 16g / ft 3 , the loading of precious metal Rh is 0.4g / ft 3 .

[0049] The preparation method is as follows:

[0050] Add 1500g of cerium-zirconium composite oxide and activated alumina to 6000g of deionized water in turn to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com