Multi-polar-group non-vulcanized ore flotation combined collecting agent and preparation and use method thereof

A technology of combining collectors and non-sulfide minerals, applied in flotation, solid separation and other directions, can solve the problems of wasting energy and consuming heating steam, saving energy, reducing flotation costs, and achieving good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

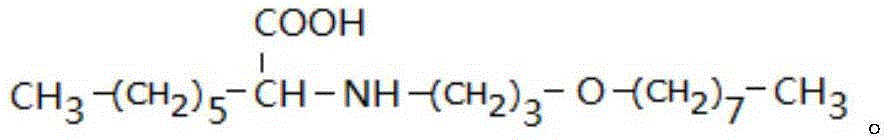

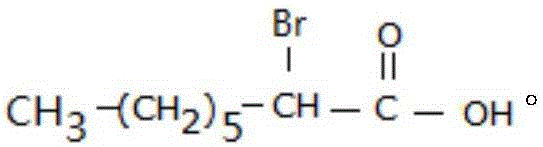

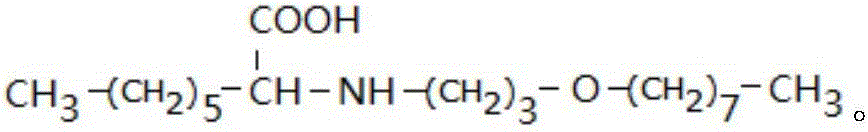

[0032] The multipolar base non-sulfide ore flotation combination collector of the present embodiment, according to mass percent, is made of 82% 1-octyloxy 5-carboxy-secondary decylamine, 9% α-bromooctanoic acid and % 3-octyl Alkoxypropylamine composition.

[0033] The preparation method of the multipolar base non-sulfide ore flotation combined collector of the present embodiment is carried out according to the following steps:

[0034] According to mass percentage, mix 82% 1-octyloxy 5-carboxy-sec-decylamine, 9% α-bromooctanoic acid and 9% 3-octyloxypropylamine in a reaction vessel, heat to 50° C. Stir evenly at a speed of 1 / min.

[0035] The using method of the multipolar base non-sulfide ore flotation combination collector of the present embodiment is carried out according to the following steps:

[0036] (1) Add the sodium hydroxide that accounts for 25% of collector gross weight in multipolar base non-sulfide ore flotation combination collector, then add water, be mixed ...

Embodiment 2

[0042] The multipolar base non-sulfide mineral flotation combination collector of the present embodiment, according to mass percent, is made of 88% 1-octyloxy 5-carboxy-secondary decylamine, 9% α-bromooctanoic acid and 3% 3- Octyloxypropylamine composition.

[0043] The preparation method of the multipolar base non-sulfide ore flotation combined collector of the present embodiment is carried out according to the following steps:

[0044] According to mass percentage, mix 88% 1-octyloxy 5-carboxy-sec-decylamine, 9% α-bromooctanoic acid and 3% 3-octyloxypropylamine in a reaction vessel, heat to 50° C. Stir evenly at a speed of 1 / min.

[0045] The using method of the multipolar base non-sulfide ore flotation combination collector of the present embodiment is carried out according to the following steps:

[0046] (1) Add the sodium hydroxide that accounts for 25% of collector gross weight in multipolar base non-sulfide ore flotation combination collector, then add water, be mixe...

Embodiment 3

[0052] The multipolar base non-sulfide ore flotation combination collector of the present embodiment, according to mass percent, is made of 90% 1-octyloxy 5-carboxy-secondary decylamine, 5% α-bromooctanoic acid and 5% 3- Octyloxypropylamine composition.

[0053] The preparation method of the multipolar base non-sulfide ore flotation combined collector of the present embodiment is carried out according to the following steps:

[0054] According to mass percentage, mix 90% 1-octyloxy 5-carboxy-sec-decylamine, 5% α-bromooctanoic acid and 5% 3-octyloxypropylamine in a reaction vessel, heat to 50° C. Stir evenly at a speed of 1 / min.

[0055] The using method of the multipolar base non-sulfide ore flotation combination collector of the present embodiment is carried out according to the following steps:

[0056] (1) Add the sodium hydroxide that accounts for 25% of collector gross weight in multipolar base non-sulfide ore flotation combination collector, then add water, be mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com