Method and device for drying abelmoschus manihot flowers by means of abelmoschus manihot waste

A technology of hollyhock flower and hollyhock, which is applied in the field of comprehensive utilization of traditional Chinese medicinal materials, achieves the effects of reasonable process design, overcoming high operating costs, and saving external energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

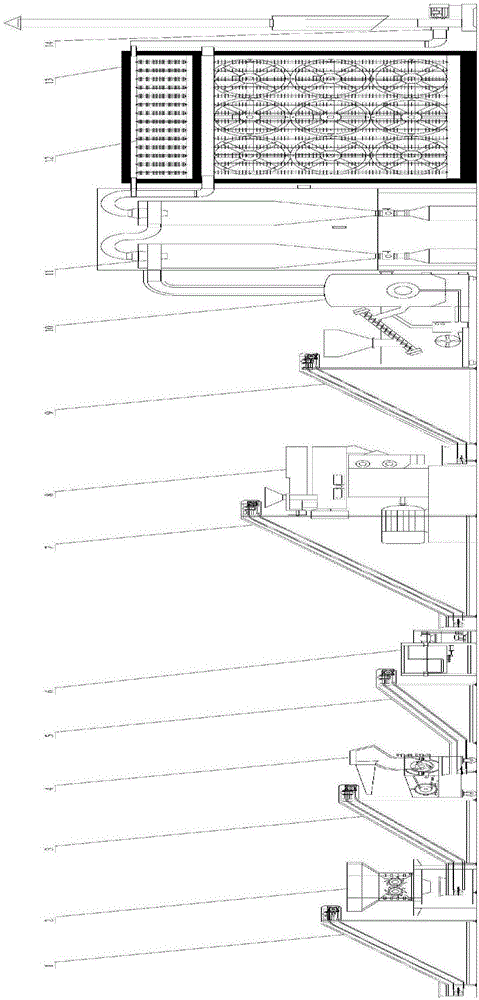

[0021] Such as figure 1 Shown, a kind of device utilizing hollyhock waste to dry hollyhock flower, it comprises the first lifting feeder (1) that is connected successively, shredder (2), the second lifts feeder (3), breaker ( 4), the third lifting feeder (5), the mixer (6), the fourth lifting feeder (7), the biomass pellet machine (8), the fifth lifting feeder (9), the biomass Combustor (10), through cyclone separator (11), two-way circulation drier (13); In described two-way circulation drier (13), flue gas heat exchanger (12) is installed, flue gas heat exchanger ( 12) Link to each other with the centrifugal exhaust machine (14).

Embodiment 2

[0023] A method of using hollyhock waste to dry hollyhock flowers is characterized in that it comprises the following steps:

[0024] A. Sun-dry or dry the discarded hollyhock stems and leaves and the hollyhock flower dregs after extracting the medicine until the water content is within 10%;

[0025] B, the dried hollyhock stems and leaves and hollyhock flower dregs are transported to the shredder (2) through the first lifting feeder (1) and shredded, and then transported to the shredder (2) through the second lifting feeder (3) Broken in the crusher (4), obtain 40 order hollyhock stems and leaves and hollyhock flower slag powder respectively;

[0026] C, the hollyhock stem leaves and hollyhock flower slag powder are not in the weight ratio of 20: 1, and are transported to the mixer (6) through the third lifting feeder (5) to mix evenly, then through the 4th lifting feeder ( 7) be transported in the biomass pellet machine (8), press the compression ratio of 6 to be compressed...

Embodiment 3

[0031] A method of using hollyhock waste to dry hollyhock flowers is characterized in that it comprises the following steps:

[0032] A. Sun-dry or dry the discarded hollyhock stems and leaves and the hollyhock flower dregs after extracting the medicine until the water content is within 8%;

[0033] B, the dried hollyhock stems and leaves and hollyhock flower dregs are transported to the shredder (2) through the first lifting feeder (1) and shredded, and then transported to the shredder (2) through the second lifting feeder (3) Broken in the crusher (4), obtain 60 order hollyhock stems and leaves and hollyhock flower slag powder respectively;

[0034] C, the hollyhock stem leaves and hollyhock flower slag powder are not in the weight ratio of 25:1, and are transported to the mixer (6) through the third lifting feeder (5) to mix evenly, then through the 4th lifting feeder ( 7) be transported in the biomass pellet machine (8), press the compression ratio of 4 to be compressed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com