Method for synthesizing Cu2+ adsorbing resin by using carboxymethyl potato starch as raw material

A potato starch and carboxymethyl technology, which is applied in the fields of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of poor crop growth, polluted grain grains, and peculiar smell, and achieves low cost. , strong water solubility, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

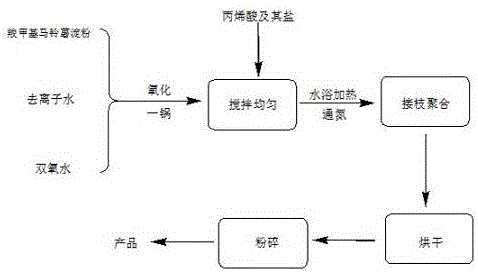

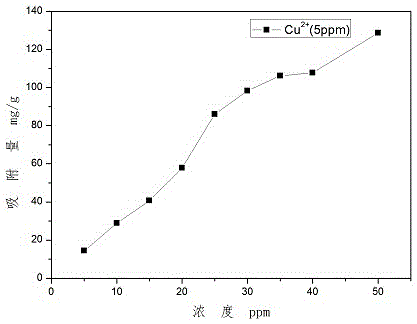

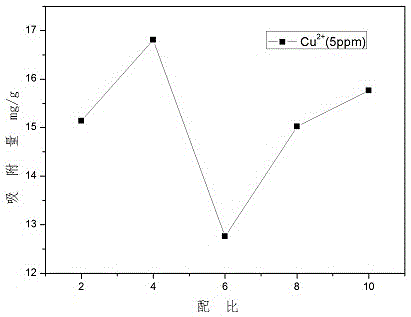

[0025] Embodiment 4: through L 9 (3 4 ) Orthogonal experiments obtained synthetically adsorbed Cu 2+ The optimum condition of resin, specific embodiment is as follows:

[0026] Weigh 5g of carboxymethyl potato starch and mix with 40ml of deionized water evenly, add 6ml of hydrogen peroxide and oxidize at 50°C for 1h, measure 20g (19.05ml) of acrylic acid, weigh 5.6g of sodium hydroxide and dissolve in 20ml of deionized water, use The above-prepared sodium hydroxide solution neutralizes acrylic acid under cooling in an ice-water bath, fully mixes the neutralized acrylic acid and its sodium salt solution with the oxidized carboxymethyl potato starch solution, and adds 1ml to a concentration of 2.5mg / ml N, N'-methylenebisacrylamide solution, in N 2 Under protection, heat slowly to increase the temperature of the system gradually. After the polymerization reaction starts, stop stirring, continue to slowly raise the temperature, keep warm at 80°C for 2 hours, dry and pulverize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com