Sustained-release antioxidant food packaging film and method for preparing same

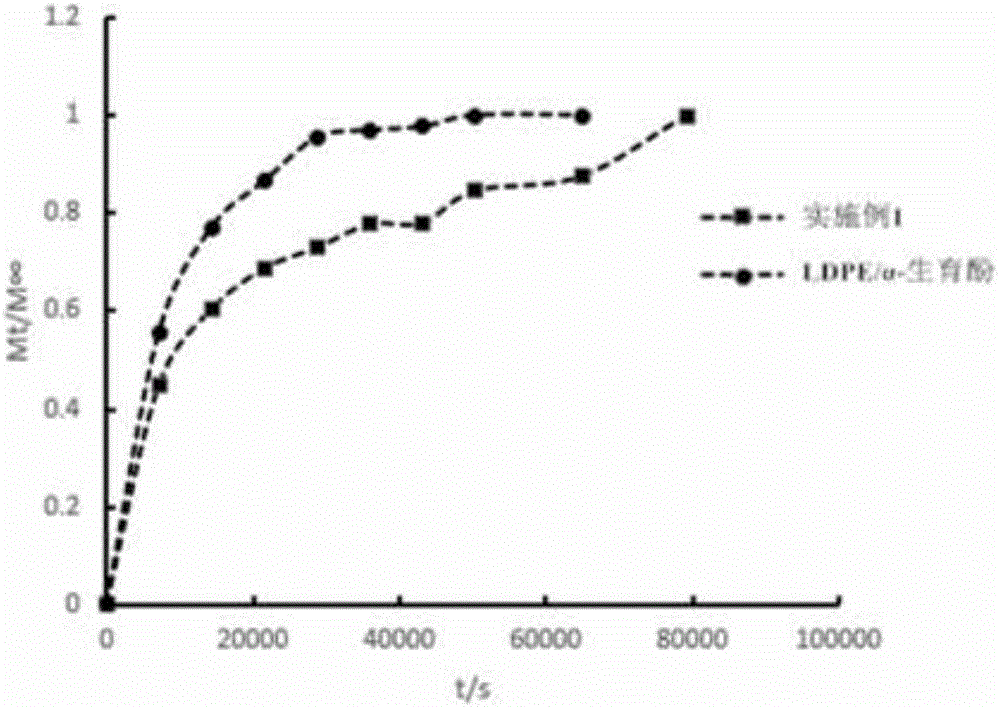

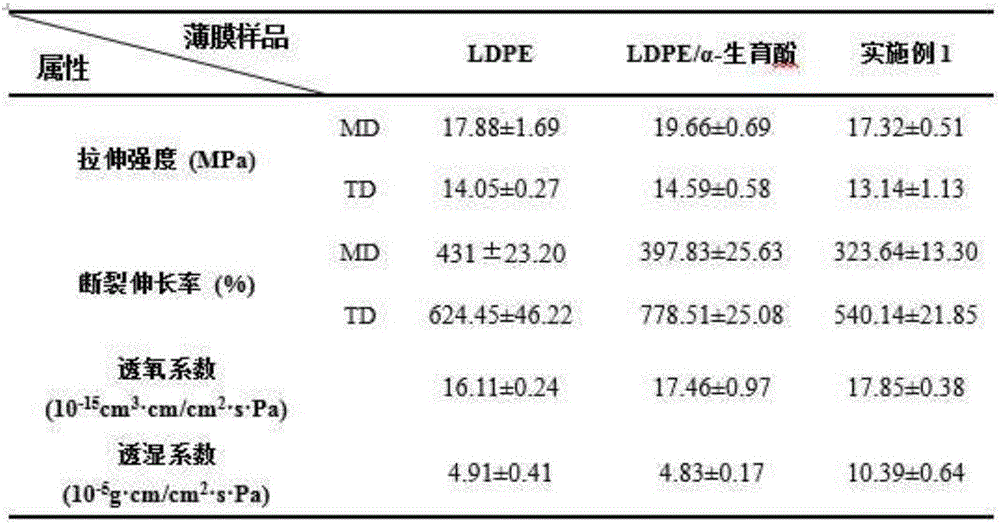

An oxidative food and sustained-release technology, which is used in the field of antioxidant active food packaging materials and the preparation of sustained-release antioxidant films, can solve the problem of reducing the release rate, prolonging the action time of antioxidants, and releasing too fast active substances with sustained-release effects, etc. problems, to achieve the effect of prolonging the action time, prolonging the shelf life, and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Present embodiment packaging film preparation steps are as follows:

[0019] (1) Dissolve 4.308g of α-tocopherol in 40mL of ethanol, add 2g of MCM-41 to the solution, stir magnetically at room temperature for 3 hours and then filter it with a sand core funnel, and dry the obtained solid in a vacuum oven at 35°C overnight to obtain Assembly.

[0020] (2) Weigh 2g of the assembly obtained in step 1), mix it evenly with 200g of LDPE masterbatch, add it to the feed hopper of a twin-screw extrusion granulator preheated at 175°C, set the screw speed to 60rpm, and granulate .

[0021] (3) Pour the blended masterbatch prepared in step (2) into the feed hopper of a single-screw extrusion casting machine preheated at 175° C., and set the screw speed at 30 rpm to prepare a film. The prepared films were stored away from light and vacuum-sealed until sampling and testing.

Embodiment 2

[0023] Present embodiment packaging film preparation steps are as follows:

[0024] (1) Dissolve 2.58g of α-tocopherol in 20mL of ethanol, add 2g of MCM-41 to the solution, stir magnetically at room temperature for 3 hours, then filter it with a sand core funnel, and dry the obtained solid in a vacuum oven at 35°C overnight to obtain Assembly.

[0025] (2) Weigh 1g of the assembly obtained in step 1), mix it evenly with 200g of LDPE masterbatch, add it to the feed hopper of a twin-screw extrusion granulator preheated at 175°C, set the screw speed to 60rpm, and granulate .

[0026] (3) Pour the blended masterbatch prepared in step (2) into the feed hopper of a single-screw extrusion casting machine preheated at 175° C., and set the screw speed at 30 rpm to prepare a film. The prepared films were stored away from light and vacuum-sealed until sampling and testing.

Embodiment 3

[0028] Present embodiment packaging film preparation steps are as follows:

[0029] (1) Dissolve 2.58g of α-tocopherol in 20mL of ethanol, add 2g of MCM-41 to the solution, stir magnetically at room temperature for 3 hours, then filter it with a sand core funnel, and dry the obtained solid in a vacuum oven at 35°C overnight to obtain Assembly.

[0030] (2) Weigh 1g of the assembly obtained in step 1), mix it evenly with 200g of polypropylene masterbatch, add it to the feed hopper of a twin-screw extrusion granulator preheated at 230°C, set the screw speed to 60rpm, Granulate.

[0031] (3) Pour the blended masterbatch prepared in step (2) into the feed hopper of a single-screw extrusion casting machine preheated at 230° C. and set the screw speed at 30 rpm to prepare a film. The prepared films were stored away from light and vacuum-sealed until sampling and testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com