Preparation method of calcium borate/graphene oxide nano composite lubricant

A nano-composite, calcium borate technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of low borate load, unfavorable industrialization, high energy consumption, etc., and achieve low cost and reduced energy consumption , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

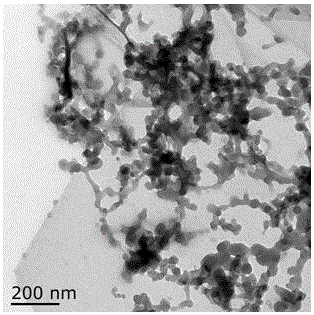

Image

Examples

example 1

[0027] Preparation process: Under ultrasonic conditions, borax is dispersed in deionized water to form a 0.1g / mL borax solution. Under ultrasonic conditions, disperse calcium chloride in deionized water to form a 0.1 g / mL calcium chloride solution.

[0028] 36mL of borax solution and 30mL of calcium chloride solution were mixed and stirred at 80°C for 1 hour to obtain a cloudy solution of calcium borate.

[0029] A graphene oxide (GO) aqueous solution with a concentration of 0.01 g / mL was formulated with deionized water and graphene oxide (GO).

[0030] Add 80mL of graphene oxide solution with a concentration of 0.01g / mL to the calcium borate turbid solution dropwise, stir at 60°C for 1h, transfer the mixed system to an ultrasonic tank at 60°C for 1h, and filter it with a Buchner funnel after natural cooling , the solid phase obtained by filtration was washed three times with deionized water, and finally the reactant was vacuum-dried at 60° C. for 5 h, and the product was obt...

example 2

[0034] Preparation process: Under ultrasonic conditions, borax is dispersed in deionized water to form a 0.1g / mL borax solution. Under ultrasonic conditions, disperse calcium chloride in deionized water to form a 0.1 g / mL calcium chloride solution.

[0035] 36mL of borax solution and 30mL of calcium chloride solution were mixed and stirred at 100°C for 1 hour to obtain a cloudy solution of calcium borate.

[0036] A graphene oxide (GO) aqueous solution with a concentration of 0.02 g / mL was formulated with deionized water and graphene oxide (GO).

[0037] Add 100mL of graphene oxide solution with a concentration of 0.02g / mL to the calcium borate turbid solution dropwise, stir at 50°C for 0.5h, transfer the mixed system to an ultrasonic tank at 70°C for 2h, cool naturally, and use a Buchner funnel to After filtration, the solid phase obtained by filtration was washed 4 times with deionized water, and finally the reactant was vacuum-dried at 100° C. for 6 h, and the product was ...

example 3

[0041] Preparation process: Under ultrasonic conditions, borax is dispersed in deionized water to form a 0.1g / mL borax solution. Under ultrasonic conditions, disperse calcium chloride in deionized water to form a 0.1 g / mL calcium chloride solution.

[0042] 36mL of borax solution and 30mL of calcium chloride solution were mixed and stirred at 80°C for 1 hour to obtain a cloudy solution of calcium borate.

[0043] A graphene oxide (GO) aqueous solution with a concentration of 0.01 g / mL was formulated with deionized water and graphene oxide (GO).

[0044]Add 120mL of graphene oxide solution with a concentration of 0.01g / mL to the calcium borate turbid solution dropwise, stir at 70°C for 0.5h, then transfer the mixed system to an ultrasonic pool at 80°C for 3h, cool naturally, and use a Buchner funnel to After filtration, the solid phase obtained by filtration was washed 5 times with deionized water, and finally the reactant was vacuum-dried at 100° C. for 8 hours, and the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com