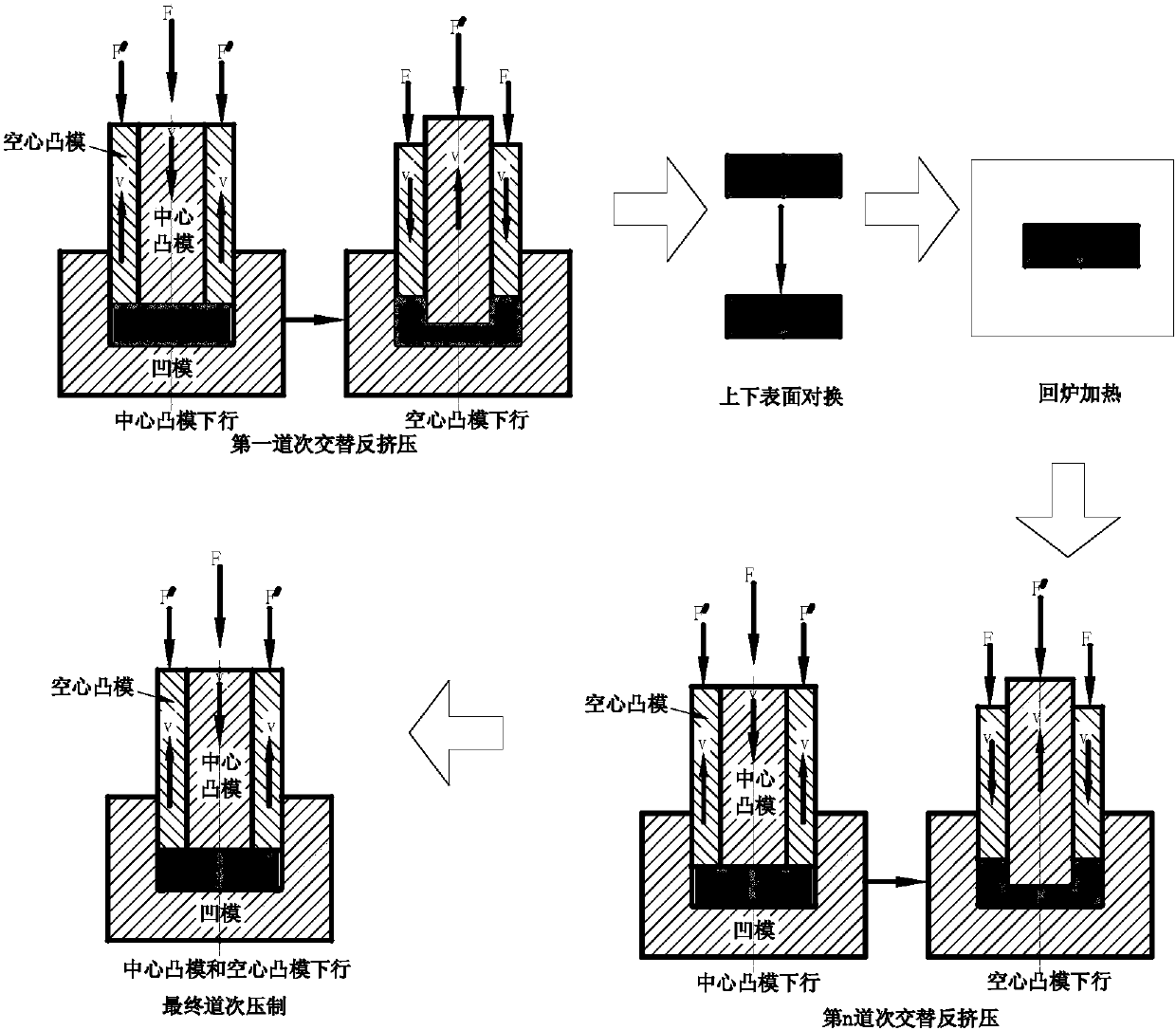

A method for preparing fine-grained magnesium alloy by alternate reverse extrusion

A magnesium alloy, reverse extrusion technology, applied in the field of magnesium alloy processing, achieves the effects of simple equipment, expanded application scope, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a fine-grained magnesium alloy by alternate back extrusion, comprising the steps of:

[0034] Step 1, cutting:

[0035] Cutting the extruded AZ31 magnesium alloy rod into a magnesium alloy cylindrical rod, wherein the outer diameter of the magnesium alloy cylindrical rod is 80 mm, and the height of the cylindrical rod is 30 mm;

[0036] Step 2, bar heat treatment:

[0037] Put the magnesium alloy cylindrical rod into the heating furnace, heat it to the extrusion opening temperature of 350°C at a heating rate of 10°C / s, and keep it warm for 60min;

[0038] Step 3, mold preheating:

[0039] Put the central punch, hollow punch and die into the mold heater and preheat to 200°C; the outer diameter of the central punch is 40mm, the inner diameter of the hollow punch is 30mm, and the outer diameter of the hollow punch is 80mm , the inner diameter of the die is 80mm, and the depth of the die is 100mm;

[0040] Step 4, Alternate back extrusion:

[004...

Embodiment 2

[0050] A method for preparing a fine-grained magnesium alloy by alternate back extrusion, comprising the steps of:

[0051] Step 1, cutting:

[0052] Cut the cast magnesium alloy rods into magnesium alloy cylindrical rods;

[0053] Step 2, bar heat treatment:

[0054] Put the magnesium alloy cylindrical rod into the heating furnace, heat it to the extrusion opening temperature of 380°C at a heating rate of 15°C / s, and keep it warm for 60min;

[0055] Step 3, mold preheating:

[0056] Put the central punch, hollow punch and die into the mold heater, and preheat to 230°C; wherein, the outer diameter of the magnesium alloy cylindrical rod is 80mm, the height of the cylindrical rod is 30mm, and the central convex The outer diameter of the mold is 40mm, the inner diameter of the hollow punch is 30mm, the outer diameter of the hollow punch is 80mm, the inner diameter of the die is 80mm, and the depth of the die is 100mm;

[0057] Step 4, Alternate back extrusion:

[0058] (1) T...

Embodiment 3

[0066] A method for preparing a fine-grained magnesium alloy by alternate back extrusion, comprising the steps of:

[0067] Step 1, cutting:

[0068] The cast magnesium alloy bar is cut into a magnesium alloy cylindrical rod; wherein, the outer diameter of the magnesium alloy cylindrical rod is 80mm, and the height of the cylindrical rod is 30mm.

[0069] Step 2, bar heat treatment:

[0070] Put the magnesium alloy cylindrical rod into the heating furnace, heat it to the extrusion opening temperature of 300°C at a heating rate of 10°C / s, and keep it for 90min;

[0071] Step 3, mold preheating:

[0072] Put the central punch, hollow punch and die into the mold heater and preheat to 180°C; the outer diameter of the central punch is 40mm, the inner diameter of the hollow punch is 30mm, and the outer diameter of the hollow punch is 80mm, the inner diameter of the die is 80mm, and the depth of the die is 100mm;

[0073] Step 4, Alternate back extrusion:

[0074] (1) The first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com