A kind of fibrous biochar and its preparation method and application

A biochar and fibrous technology, applied in the field of environmental engineering, can solve problems such as resource waste and environmental pollution, achieve high iodine adsorption value, simplify the process flow, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030]

[0031] A preparation method for fibrous biochar, comprising the steps of:

[0032] (1), preprocessing steps:

[0033] Soak the textile in the treatment agent at 80±10°C and keep stirring, squeeze out the water after 30±10min, and then dry it with hot air at 60±10°C to obtain the treated product.

[0034] Wherein, the treating agent is a mixture of nitrate and phosphate in a molar ratio of 1:(1-3).

[0035] The molar concentration of the nitrate solution can be 0.2-0.8mol / L, and the molar concentration of the phosphate solution can be 0.1-0.4mol / L.

[0036] The nitrate contained in the nitrate solution may be sodium nitrate or potassium nitrate, and the phosphate contained in the phosphate solution may be sodium phosphate or potassium phosphate.

[0037] The present invention adopts the treating agent that contains phosphate and nitrate simultaneously to carry out pretreatment to textile, and its reason is as follows:

[0038] First, phosphate contains phosphorus,...

Embodiment 1

[0070] The present embodiment provides a kind of preparation method of fibrous biochar, it comprises the steps:

[0071] (1) immerse 4.6853g of textiles in a treatment agent at 80°C and stir continuously, squeeze out the water after 30 minutes, and then dry with hot air at 60°C to obtain the treated product;

[0072] (2), pulverize the processed product obtained in step (1) into a powder with a particle size of ≤20 mesh, and continue to carry out hot air drying at 60°C until the moisture content of the powder is ≤10%; if the moisture content is ≤10% , it is not necessary to carry out hot air drying;

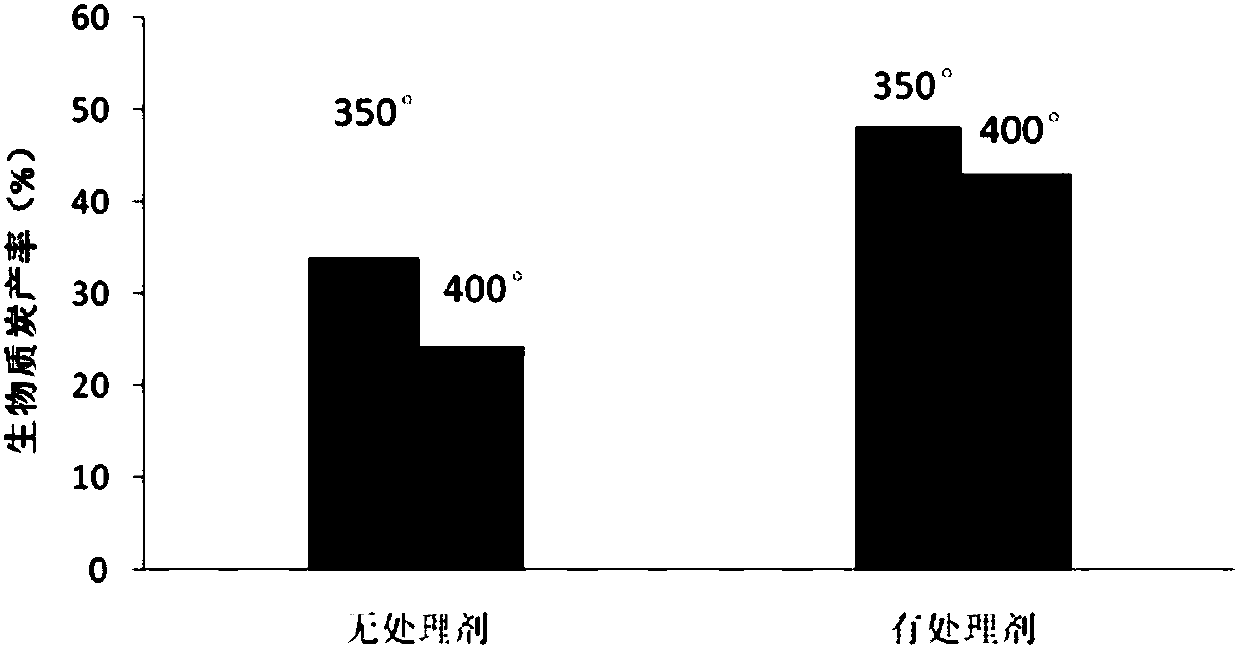

[0073] (3), the powder obtained in step (2) is heated up to 350° C. under the protection of nitrogen with a heating rate of 5° C. / min for carbonization, and the carbonization time is 1.5 hours to obtain 2.1459 g of fibrous biochar (such as figure 2 shown).

[0074] Wherein, in the step (1), the treatment agent is a mixed solution composed of a nitrate solution and a phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com