Rope-driven parallel robot motion control method in consideration of elasticity effect and compensation

A technology of robot movement and control method, which is applied in the field of robotics and can solve problems such as low movement precision and low system rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

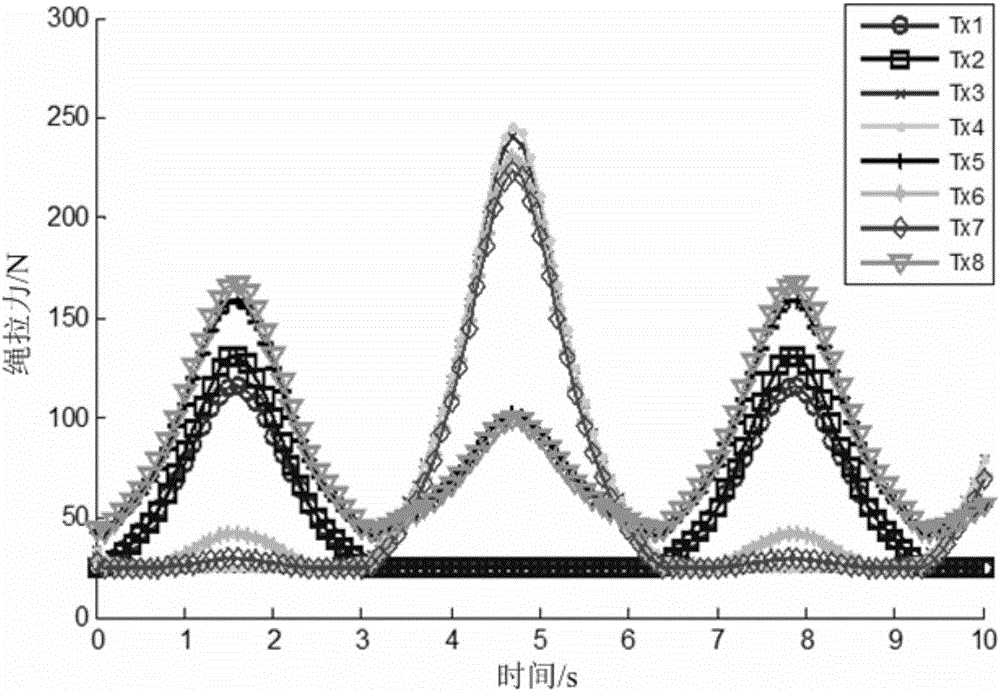

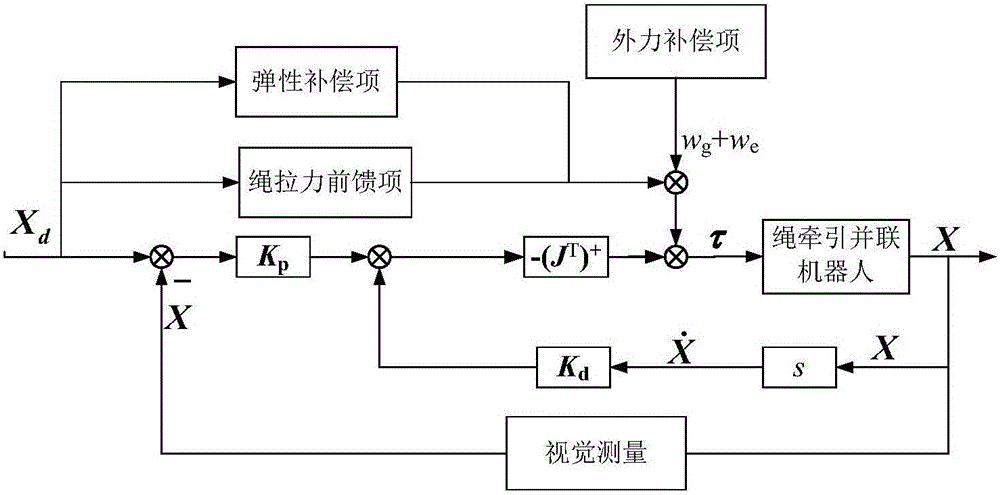

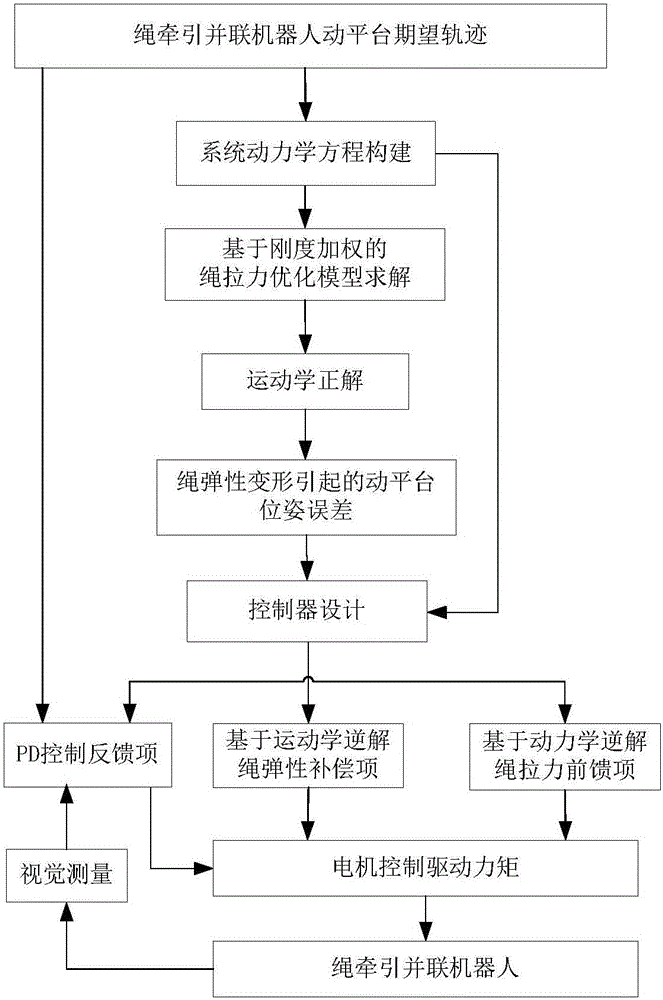

[0063] The proposed motion control method of a rope-pulled parallel robot considering the effect and compensation of rope elasticity is applied to a six-degree-of-freedom parallel robot pulled by eight ropes. The parallel robot is as follows: image 3 As shown, the moving platform 1 takes the aircraft model as an example, which is pulled by eight traction ropes 2; the pulley 3 is fixed on the frame 4; the length of the traction rope 2 is adjusted by the motor through the pulley 3, thereby changing the position and attitude of the aircraft model 1; The pose of the aircraft model 1 can be obtained by measuring the monocular vision 5 , which is installed on the gimbal 6 fixed on the frame 7 . The control method of this embodiment is implemented as follows:

[0064] 1) Error analysis of moving platform 1 caused by elastic deformation of traction rope 2

[0065] According to the definition of the coordinate system, the origin of the static coordinate system is located at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com