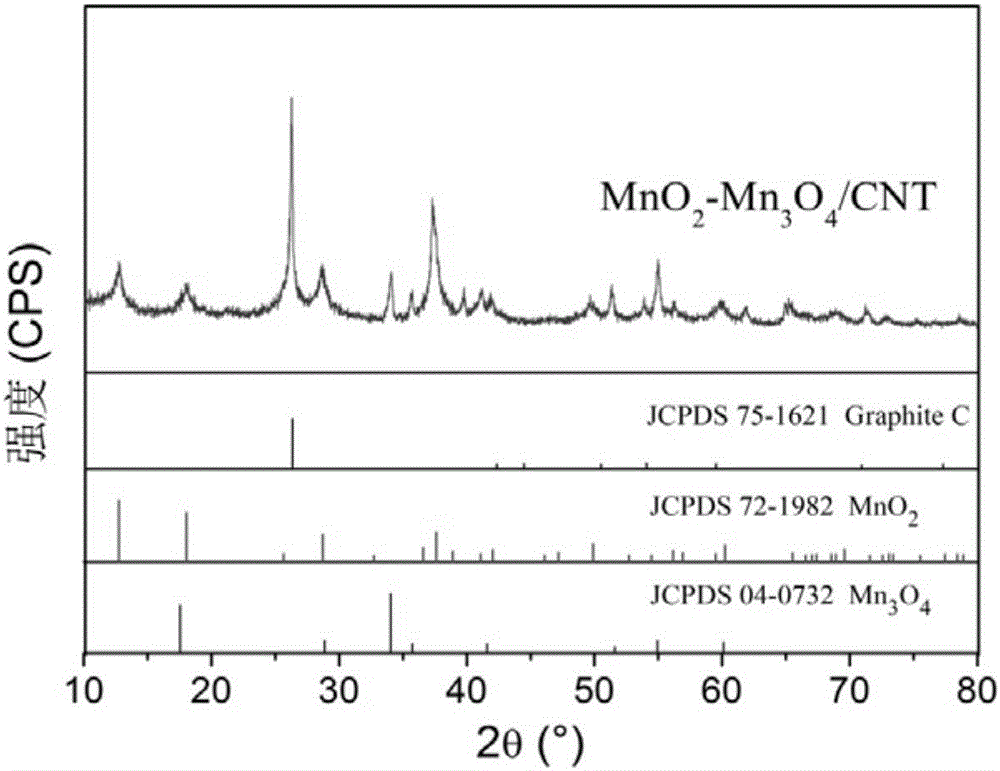

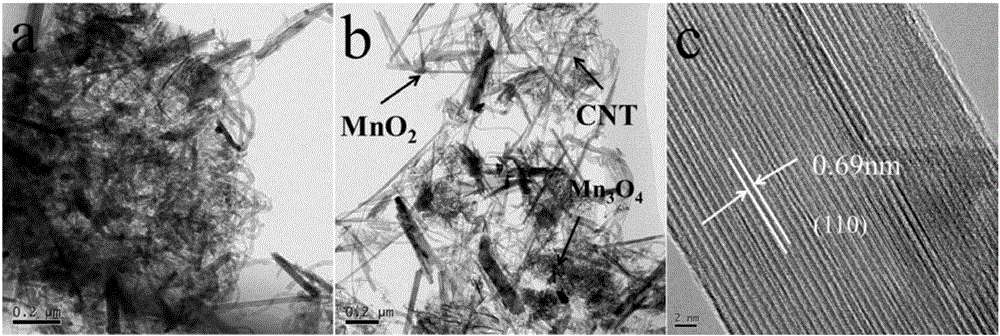

High-performance oxygen reduction MnO2-Mn3O4/carbon nanotube composite catalyst and preparation method and application thereof

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of electrocatalysis, can solve the problems of low activity and conductivity, and achieve the effects of simple preparation method, obvious synergistic effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] MnO 2 -Mn 3 O 4 / The preparation of carbon nanotubes is divided into two steps, as follows:

[0028] (1) Preparation of oxidized carbon nanotubes

[0029] Oxidized carbon nanotubes were synthesized using a modified Hummers method. Weigh 1 g of multi-walled carbon nanotubes into a 250 mL round-bottomed flask, slowly add 23 mL of concentrated sulfuric acid, and stir for 24 h. Transfer the round bottom flask to a 35 °C water bath and add 0.2 g NaNO 3 and keep stirring. To be NaNO 3 After dissolving, add 1g KMnO very slowly 4 , to be KMnO 4 After the addition, the stirring was continued for 120 min. Slowly add 46 mL of deionized water, transfer to a 98°C water bath and heat for 30 min, remove and cool to room temperature and stir continuously, add 140 mL of deionized water and 10 mL of 30% hydrogen peroxide in sequence and stir for 5 min. The oxidized carbon nanotubes in the suspension were collected by centrifugation. During the centrifugation process, they were...

Embodiment 2

[0036] According to the method of Example 1, in MnO 2 -Mn 3 O 4 25 mg of oxidized carbon nanotubes were added to the preparation of carbon nanotubes.

[0037] The evaluation method of catalytic performance is the same as that of Example 1.

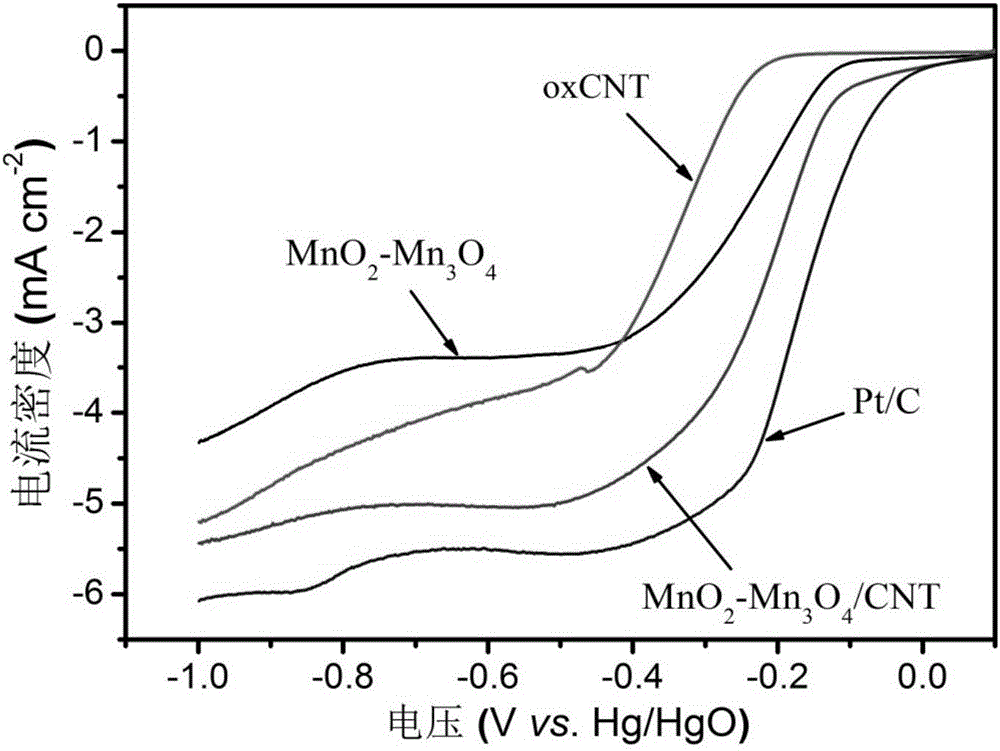

[0038] The obtained MnO 2 -Mn 3 O 4 The onset potential of the composite / carbon nanotube composite as ORR catalyst is -0.09V (vs.Hg / HgO), the half-wave potential is -0.22V (vs.Hg / HgO), and the limiting current density is -5.6mA / cm 2 . In the galvanometric evaluation, the current density retention rate was about 90% after continuous operation for 7200 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com