Preparation method of MnFe2O4 nano magnetic material

A nano-magnetic material, mnfe2o4 technology, applied in the direction of nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inability to prepare microstructures, and achieve the effects of good dispersion, simple process, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

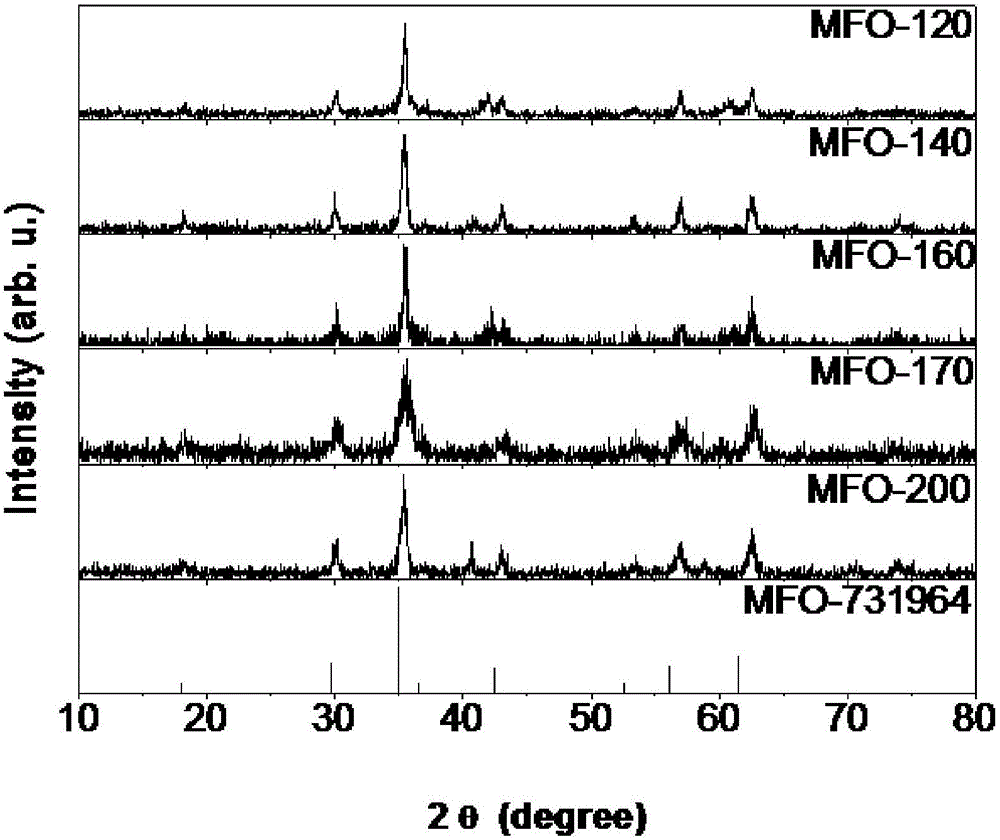

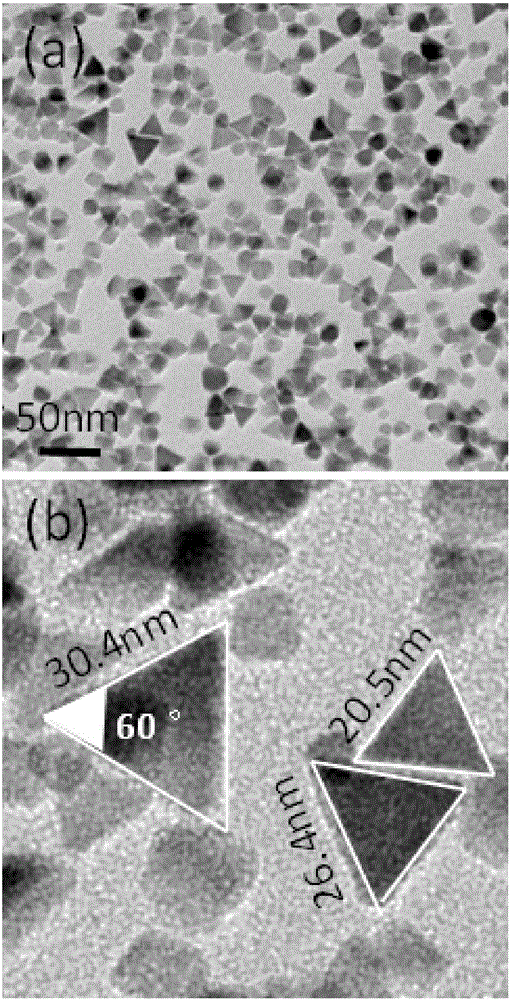

[0048] Example 1: Three-degree symmetric MnFe 2 o 4 Preparation of Nanomaterials

[0049] According to the molar ratio of manganese: iron element is 1:2, weigh 0.8678g of divalent acetylacetonate manganese salt and 2.3965g of trivalent acetylacetonate iron salt sample and dissolve them in 100ml of dibenzyl ether organic solvent. At the same time, add 20ml of oleylamine, Oleic acid, magnetically stirred at 30°C for 30mins to fully dissolve the acetylacetonate in the organic solvent, then raised the temperature to 120°C for 15 minutes, then raised the temperature to 200°C for 2 hours, and finally raised the temperature to 290°C for 1 hour, removed the heating device, and cooled naturally to room temperature, add an appropriate amount of alcohol to wash until the solution is completely clear, and dry to obtain a three-degree symmetrical MnFe 2 o 4 Nanoparticle samples.

Embodiment 2

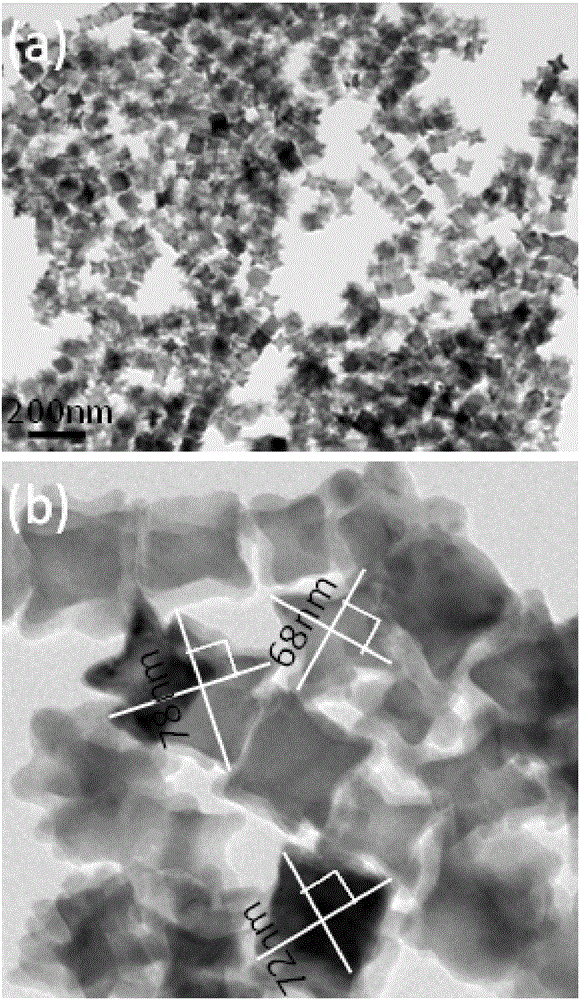

[0050] Embodiment 2, four-degree symmetric MnFe 2 o 4 Preparation of Nanomaterials

[0051] According to the molar ratio of manganese: iron element is 1:2, weigh 0.8678g of divalent acetylacetonate manganese salt and 2.3965g of trivalent acetylacetonate iron salt sample and dissolve them in 100ml of dibenzyl ether organic solvent. At the same time, add 20ml of oleylamine, Oleic acid, magnetic stirring at 30°C for 30mins to fully dissolve the acetylacetonate in the organic solvent, then raise the temperature to 140°C, remove the heat source, naturally cool down to 120°C for 15 minutes, then raise the temperature to 200°C for 2 hours, and finally raise the temperature to 290°C Constant temperature for 1h, remove the heating device, cool to room temperature naturally, add appropriate amount of alcohol to wash until the solution is completely clear, and dry to obtain four-degree symmetrical MnFe 2 o 4 Nanoparticle samples.

Embodiment 3

[0052] Example 3: Four-degree symmetric MnFe 2 o 4 Preparation of Nanomaterials

[0053] According to the molar ratio of manganese: iron element is 1:2, weigh 0.8678g of divalent acetylacetonate manganese salt and 2.3965g of trivalent acetylacetonate iron salt sample and dissolve them in 100ml of dibenzyl ether organic solvent. At the same time, add 20ml of oleylamine, Oleic acid, magnetic stirring at 30°C for 30 minutes to fully dissolve the acetylacetonate salt in the organic solvent, then raise the temperature to 150°C, remove the heat source, naturally cool down to 120°C for 15 minutes, then raise the temperature to 200°C for 2 hours, and finally raise the temperature to 290°C Constant temperature for 1h, remove the heating device, cool to room temperature naturally, add appropriate amount of alcohol to wash until the solution is completely clear, and dry to obtain four-degree symmetrical MnFe 2 o 4 Nanoparticle samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com