Method for recrystallizing TATB

A recrystallization and crystal form technology, applied in organic chemistry, amino compound purification/separation, etc., can solve the problems of high sulfuric acid impurity content, danger, difficult control of crystal shape and particle size, etc., and achieve simple reaction operation and mild reaction conditions , the effect of controllable particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

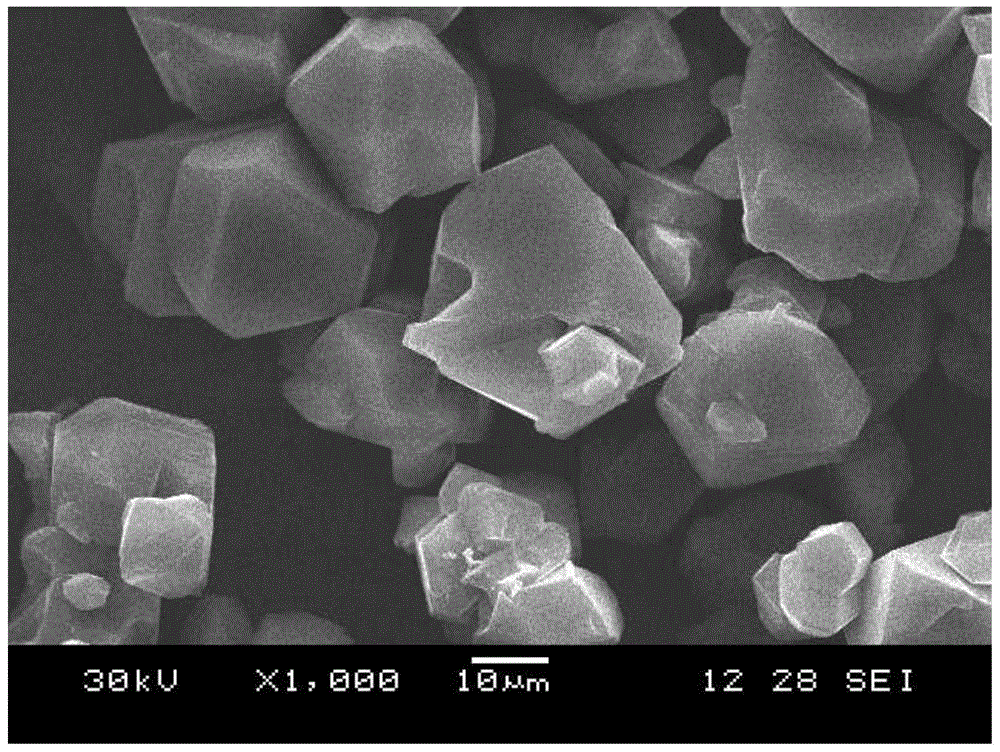

[0021] Add 0.200 g TATB, 50ml DMSO and 0.496% TW-20 into a four-neck flask, heat it in an oil bath to 125°C under constant stirring, TATB is completely dissolved, and keep it warm for 10 minutes. Cool down to 75°C at 1°C / min, then cool naturally to room temperature, filter to obtain TATB, wash with water and ethanol for 2-3 times in turn, and then dry at 110°C to obtain TATB product. The purity of TATB was 99.82% by HPLC analysis, and the exothermic decomposition temperature was 378.93°C by DSC analysis. The particle size of TATB measured by micron particle size tester was 10.64 μm. Scanning electron microscope SEM shows that the crystal shape of TATB is relatively regular and the surface is relatively smooth, such as figure 1 shown.

Embodiment 2

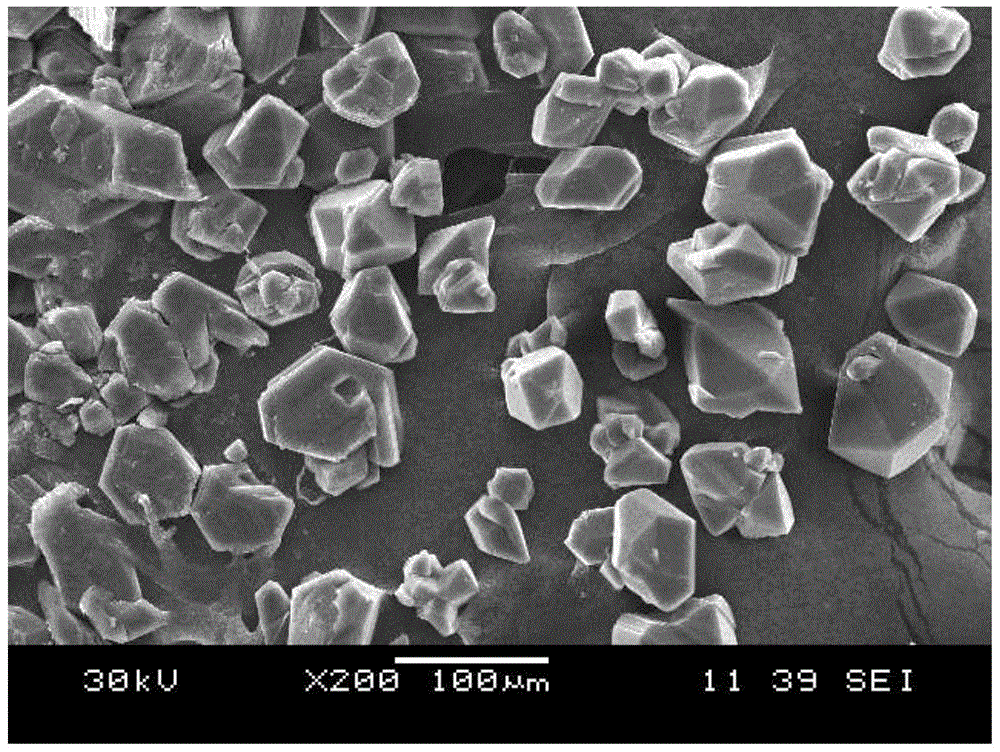

[0023] Add 0.200 g TATB, 50ml DMSO and 0.514% SPAN-85 into a four-neck flask, heat it in an oil bath to 125°C under constant stirring, TATB is completely dissolved, and keep it warm for 20 minutes. Cool down to 75°C at 1°C / min, then cool naturally to room temperature, filter to obtain TATB, wash with ethanol 2-3 times, and dry at 110°C to obtain TATB product. The purity of TATB was 99.79% by HPLC analysis, and the exothermic decomposition temperature was 379.62°C by DSC analysis. The particle size of TATB measured by micron particle size tester was 11.38 μm. Scanning electron microscope (SEM) showed that the crystal shape of TATB was relatively regular, the surface was relatively smooth, and a small amount of small grains adhered.

Embodiment 3

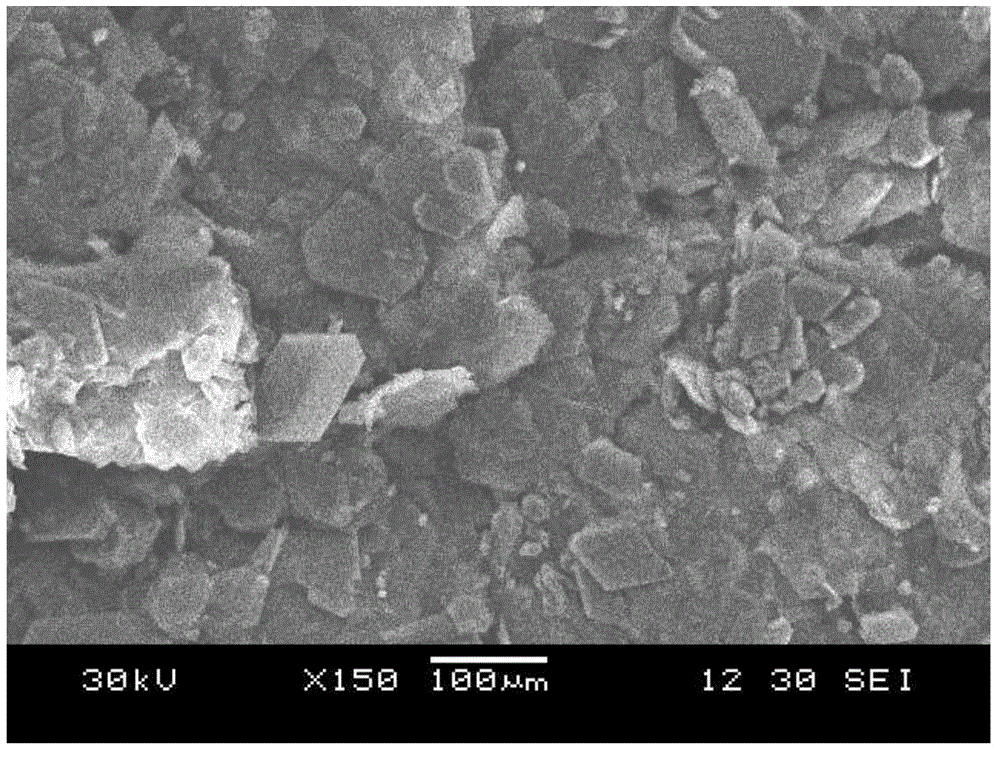

[0025] Add 0.150 g TATB, 50 ml DMSO and 0.478% benzyltriethylammonium chloride into a four-neck flask, heat to 115°C in an oil bath with constant stirring, TATB is completely dissolved, and keep the reaction for 10 min. Stir continuously at a speed of 1 min, cool down to room temperature at 1°C / min, filter to obtain TATB, wash with water and ethanol for 2-3 times in turn, and dry at 100°C to obtain TATB product. The purity of TATB was 99.84% by HPLC analysis, and the exothermic decomposition temperature was 381.96°C by DSC analysis. Scanning electron microscope SEM shows that the crystal form of TATB is relatively regular flake, and the surface is relatively smooth, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com