Method for preparing 1, 4-dioxane

A technology of dioxane and dimethyl ether, applied in the field of solid acid catalysis, to achieve the effects of highlighting environmental friendliness, avoiding environmental pollution, and eliminating industrial wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The H-ZSM-5 molecular sieve with a silicon-aluminum ratio of Si / Al=50 is pressed into tablets under a pressure of 40 MPa and crushed to 20-40 mesh to obtain a catalyst.

[0057] 1 g of catalyst was filled into a fixed bed reactor for pretreatment. Catalyst pretreatment conditions are: N 2 The flow rate is 30ml / min, rising from 25°C to 500°C over 150min, and maintaining at 500°C for 180min.

[0058] The reaction raw material ethylene glycol dimethyl ether is under the condition of water bath temperature 40 ℃, by N 2 Bring it into the reactor at a flow rate of 30ml / min, and the space velocity is 0.08h -1 , The reaction pressure is 3.0Mpa.

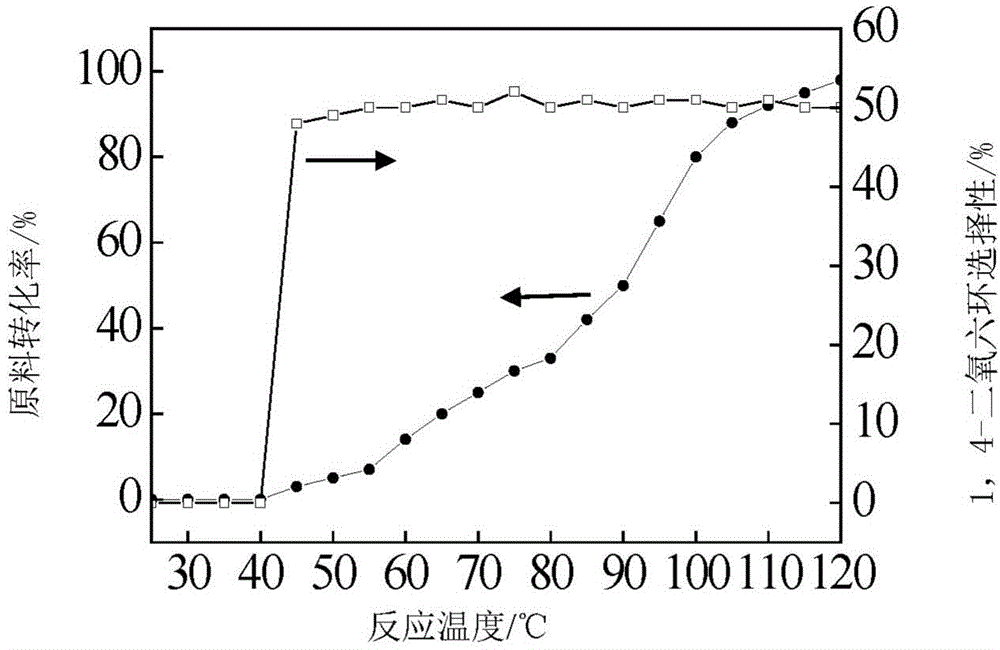

[0059] Raw material conversion rate and product selectivity change with temperature as shown in figure 1 shown. From figure 1 It can be seen in the figure that on the H-ZSM-5 (Si / Al=50) catalyst, when the reaction temperature is lower than 80°C, the conversion of raw materials is lower than 40%. However, as the reaction temperat...

Embodiment 2

[0061] The hydrogen-type mordenite with a silicon-aluminum ratio of Si / Al=14.5 was pressed into tablets under a pressure of 40 MPa and crushed to 20-40 mesh to obtain a catalyst.

[0062] 1 g of catalyst was filled into a fixed bed reactor for pretreatment. The pretreatment condition is: N 2 The flow rate is 30ml / min, rising from 25°C to 500°C over 150min, and maintaining at 500°C for 180min.

[0063] The reaction raw material ethylene glycol dimethyl ether is under the condition of water bath temperature 40 ℃, by N 2 Bring it into the reactor at a flow rate of 30ml / min, and the space velocity is 0.4h -1 , The reaction pressure is 0.5Mpa.

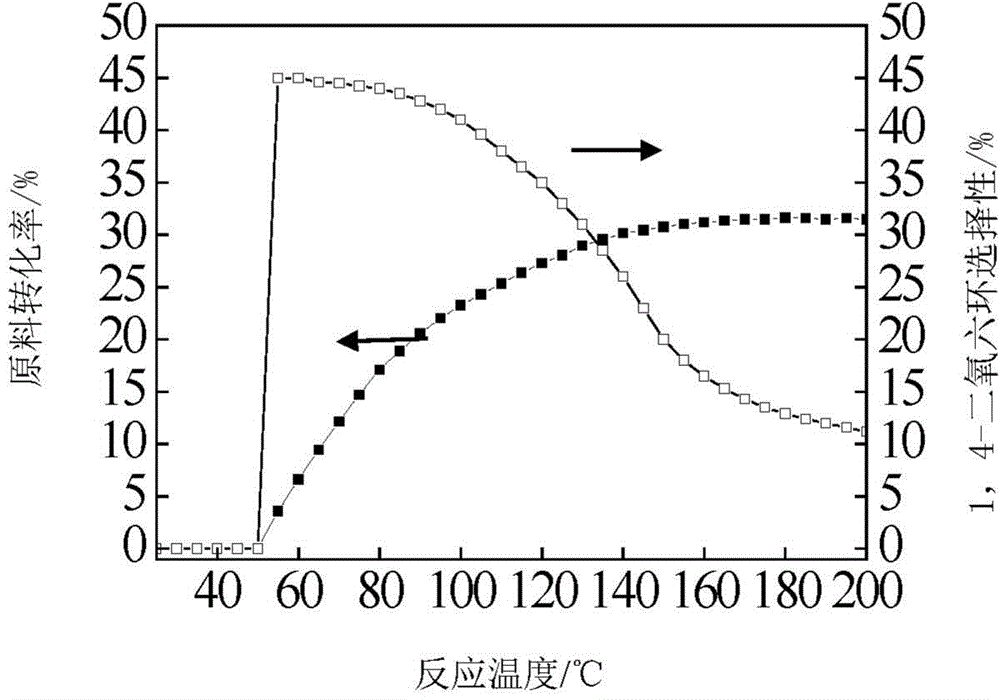

[0064] Raw material conversion rate and product selectivity change with temperature as shown in figure 2 shown. From figure 2 It can be seen that when hydrogen-type mordenite (Si / Al=14.5) is used as the catalyst, the conversion rate of raw materials gradually increases with the increase of reaction temperature. At 200°C, the convers...

Embodiment 3

[0066] The H-Beta molecular sieve with a silicon-aluminum ratio of Si / Al=16 was pressed into tablets under a pressure of 40 MPa and crushed to 20-40 mesh to obtain a catalyst.

[0067] 1 g of catalyst was filled into a fixed bed reactor for pretreatment. The pretreatment conditions are: N2 flow rate 30ml / min, starting from 25°C over 150min to 500°C, and maintaining at 500°C for 180min. The reaction raw material ethylene glycol dimethyl ether was prepared by N 2 Bring it into the reactor at a flow rate of 30ml / min, and the space velocity is 0.05h -1 , The reaction pressure is 5.0Mpa.

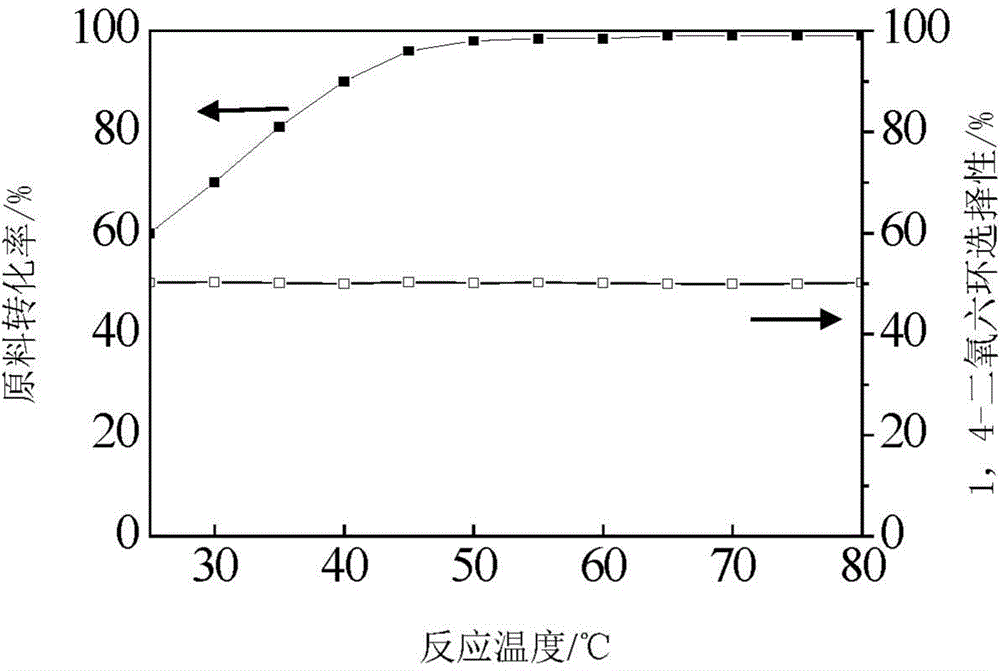

[0068] Raw material conversion rate and product selectivity change with temperature as shown in image 3 shown. From image 3 It can be seen that when using H-Beta (Si / Al=16) as a catalyst, the conversion rate of the raw material can reach 60% at a lower room temperature (25°C); when the reaction temperature is higher than 50°C, the raw material The conversion rate of ethylene glycol dimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com