Xenon light source lens automobile lamp manufactured through BMC (bulk molding compound)

A light source and car light technology, applied to electric light sources, motor vehicles, road vehicles, etc., can solve problems such as high cost, rising cost, and increased investment in new equipment, and achieve the effect of improving the progress of replacement and transformation and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

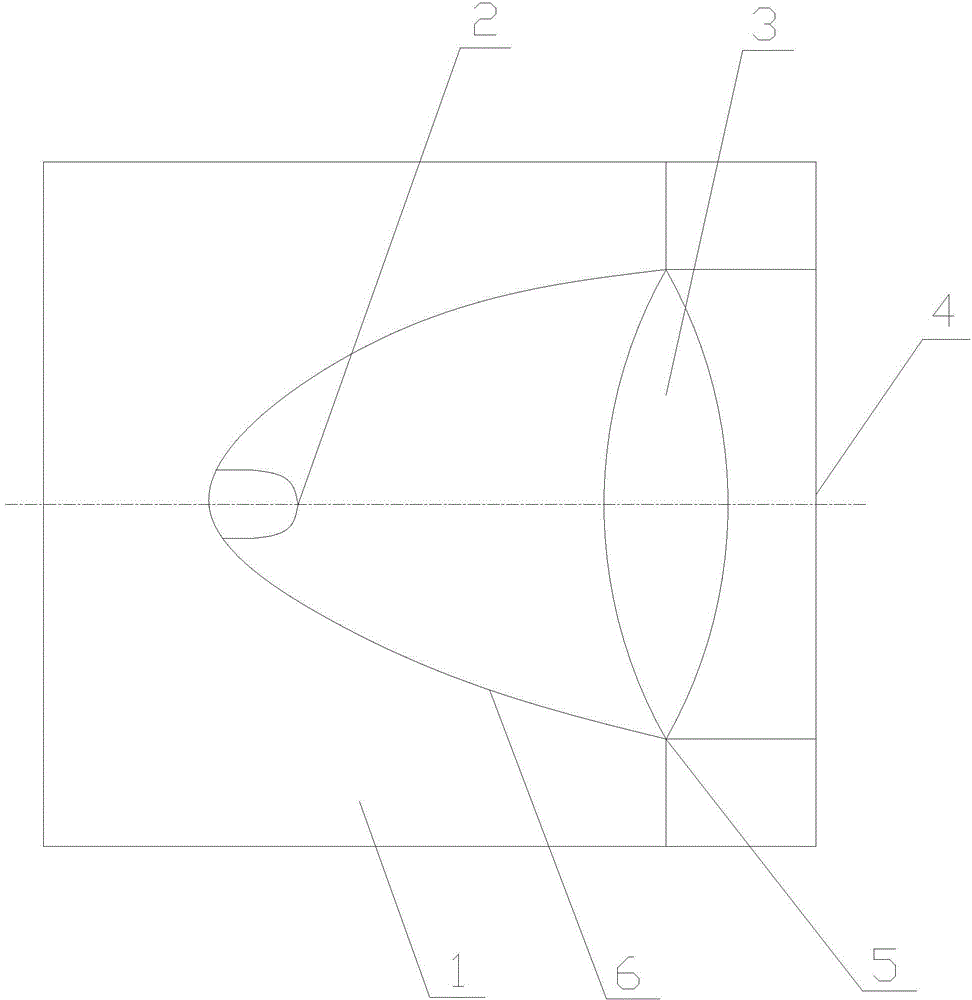

[0015] Such as figure 1 As shown, the xenon light source lens vehicle lamp made of BMC, the vehicle lamp includes a lamp holder 1, a light source 2 and a lens 3, the lamp holder 1 of the vehicle lamp is made of BMC material, and the lamp holder 1 is equipped with double The curved reflective surface 6 is provided with a light source 2 at the center of the reflective surface 6, and a lens 3 is provided in front of the light source 2, and an aluminum-plated reflective layer is provided on the surface of the reflective surface 6.

[0016] In this embodiment, the lamp holder 1 is made of BMC material through injection molding to form an integral structure, and the front of the lens 3 is arranged on the lampshade 4 . A heat insulating layer is provided between the reflective layer and the reflective surface of the lamp holder 1; the vehicle lamp is also provided with a dimming plate 5, and the surface of the dimming plate 5 is also provided with a reflective layer. The light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com