Method for measuring oil length and/or oil content of oil-based drilling cuttings and application of method

A technology of oil-based drilling cuttings and measuring methods, which is applied in the petroleum field, can solve problems such as errors, high oil content of oil-based drilling cuttings, narrow linear range of quantitative fluorescence, etc., and achieve the effect of simple method, easy operation and accurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Method of measuring oil content and oil content of oil-based drill cuttings after treatment

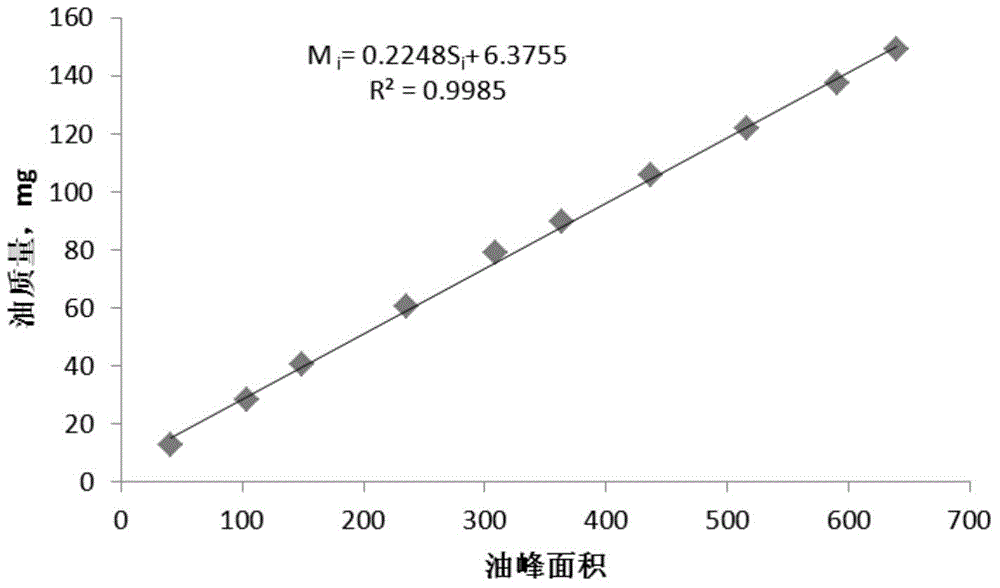

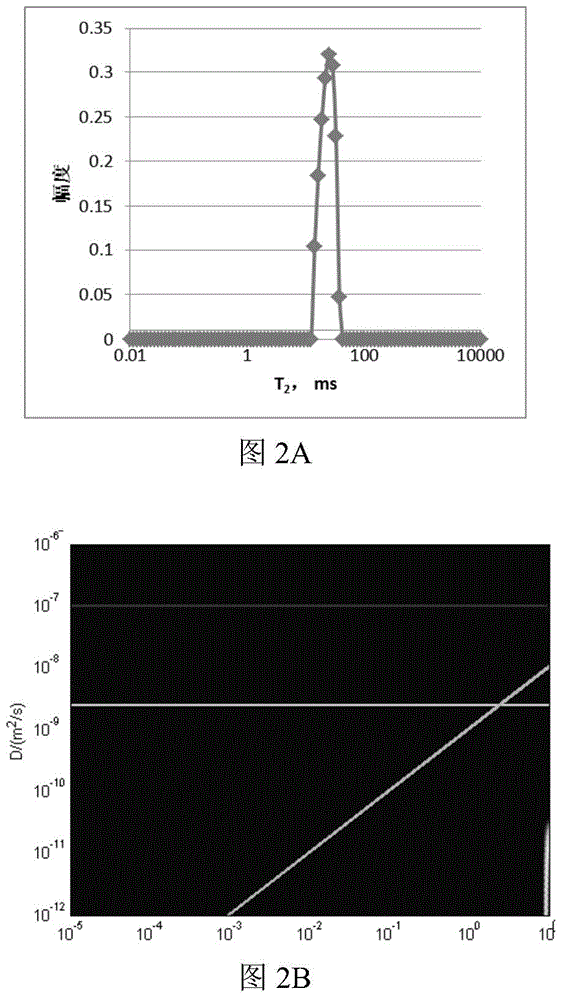

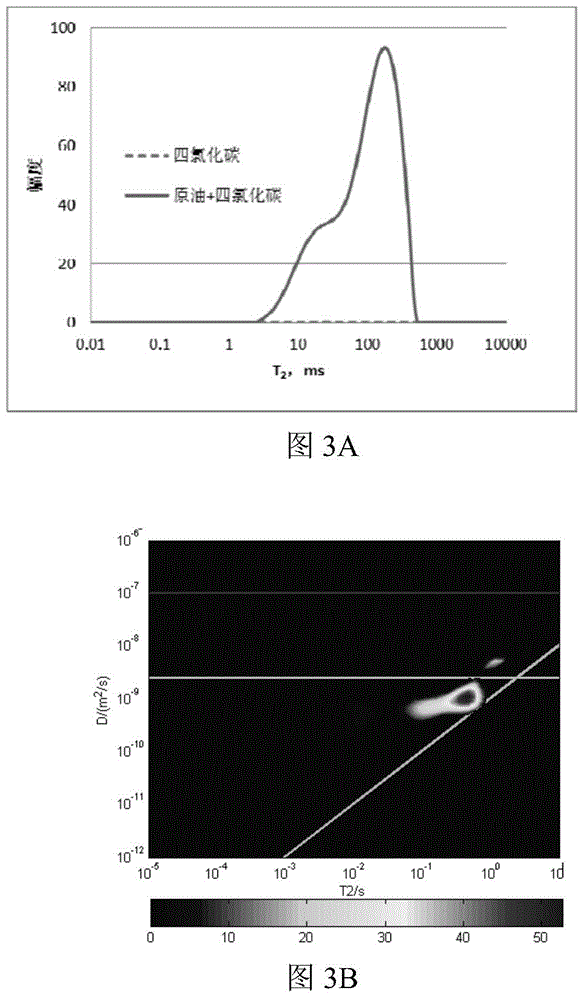

[0039] Use carbon tetrachloride solution to mix with various oil-based drilling fluid base oils of different qualities, and perform nuclear magnetic resonance measurement (the oil quality of various oil-based drilling fluid base oils of different qualities and the measured peak area of the oil sample are shown below Table 1), establish T 2 Spectral oil peak area (S i ) And base oil quality (M i ) Linear equation: M i =0.2248S i +6.3755 (see figure 1 ). Since the organic solvent does not contain hydrogen atoms, the organic reagent has no nuclear magnetic resonance signal (see figure 2 ), thus T 2 Spectrum or T 2 The peak of -D is the signal response of the base oil (see image 3 ).

[0040] Table 1

[0041] Oil sample peak area Oil quality, mg 40.8036212.9 103.89128.3 149.474240.6 235.432560.6 309.43278.9 363.520889.6 437.4061105.9 515.7525121.9 591.2319137.4 640.0...

Embodiment 2

[0050] Using the method described in Example 1, the oil-based drills treated with nanoporous tight sandstone formations (stone wheel drill bits), self-derived shale formations (PDC drill bits), and self-generating and self-storing shale formations (cone drill bits) The oil content and oil content of the chips are measured. The oil-based drill cuttings after the treatment of these different lithology and different drill bits, the carbon tetrachloride extract T 2 The oil-based drill cuttings with different lithologies and different bit types are analyzed and treated with carbon tetrachloride organic solvent. 2 See Figure 4 .

[0051] It can be seen that the method of the present invention is applicable to oil-based drill cuttings obtained from different lithologies and different types of drill bits.

Embodiment 3

[0053] The method described in Example 1 was used to measure the oil content and oil content of oil-based drill cuttings treated by centrifugal, extraction, and cleaning methods. The oil-based drill cuttings treated by these different methods are extracted with carbon tetrachloride organic solvent. 2 See Figure 5 .

[0054] It can be seen that the method of the present invention is suitable for oil-based drill cuttings treated by different treatment methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com