Treating method for discontinuous small-flow light-dydrocarbon-containing tail gas at low light dydrocarbon concentration

A treatment method and low-flow technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high energy consumption and unsuitable condensation method for hydrocarbon tail gas recovery and treatment, and achieve high treatment efficiency and savings. Energy and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

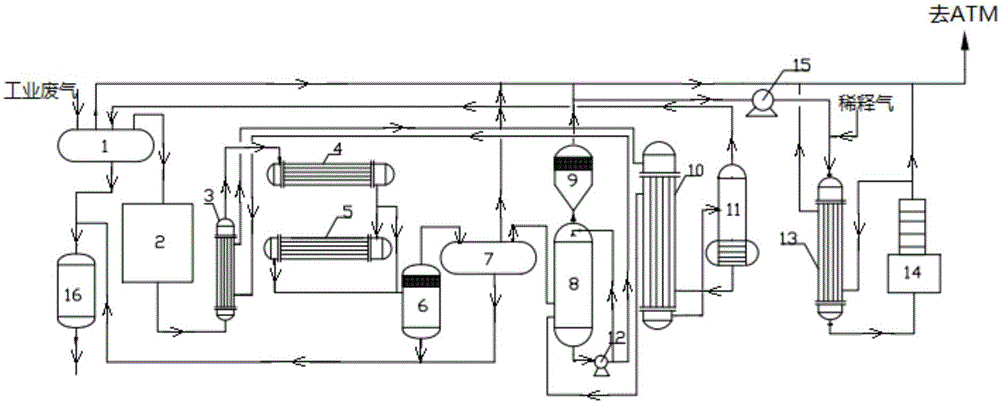

[0049] A treatment method for tail gas containing light hydrocarbons with intermittent, small flow rate and low concentration of light hydrocarbon components, which is processed by a process device as shown in Figure 1, and the treatment method specifically includes the following steps:

[0050] (a) The light hydrocarbon-containing tail gas with small flow rate and low light hydrocarbon component concentration discharged from different systems is collected into the buffer of the tail gas collection unit and cooled, wherein the condensate enters the condensate recovery tank, and the first non-condensable gas enters the step ( b) processing procedures;

[0051] (b) Pass the first non-condensable gas into the compression condensing unit for compression, heat exchange, and condensation, the condensate is passed into the condensate recovery tank, and the second non-condensable gas enters the processing procedure of step (c);

[0052] (c) The light hydrocarbon component concentratio...

Embodiment 2

[0068] The tail gas containing light hydrocarbon components and nitrogen (mostly) discharged from each unit is collected into the tail gas collection tank. The tail gas is collected and buffered in the collection tank. Under the condition of natural cooling, a small part of hydrocarbons condenses, and the condensate enters the condensate recovery tank. The preliminary measurement of the concentration of non-condensable gas at the outlet of the buffer tank is 1000g / m 3 .

[0069] The high concentration of hydrocarbon tail gas enters the process of compression and condensation treatment, in which the pressure of compressor 2 is controlled at 0.8MPa to 5.0MPa, and the temperature of the tail gas rises to about 130°C after the two-stage compression treatment of compressor 2. The gas at the outlet of the compressor 2 enters the primary water cooler 4 after heat exchange, and the cooling temperature is -10°C to 5°C to condense part of the hydrocarbons. The condensate and non-conden...

Embodiment 3

[0072] The tail gas containing light hydrocarbon components and nitrogen (mostly) discharged from each unit is collected into the tail gas collection tank. Preliminary measurement of the concentration of hydrocarbon components in the tail gas at the outlet of the buffer tank is 198g / m 3 , directly into the mineral oil absorption treatment process. After mineral oil absorption treatment, the concentration of hydrocarbon components in the tail gas is 3.96g / m 3 . Enter the catalytic oxidation link, after low-temperature catalytic oxidation and high-temperature catalytic oxidation treatment, the emissions meet the standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com