Multi-layer flame-retardant wood-based composite board and its manufacturing method

A manufacturing method and composite panel technology, applied in chemical instruments and methods, laminated, layered products, etc., can solve the problems of damage to the physical properties of flame-retardant wood-based panels, environmental and human life hazards, and difficulty in meeting fire protection standards. Achieve the effects of low cost, good environmental performance, and delayed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

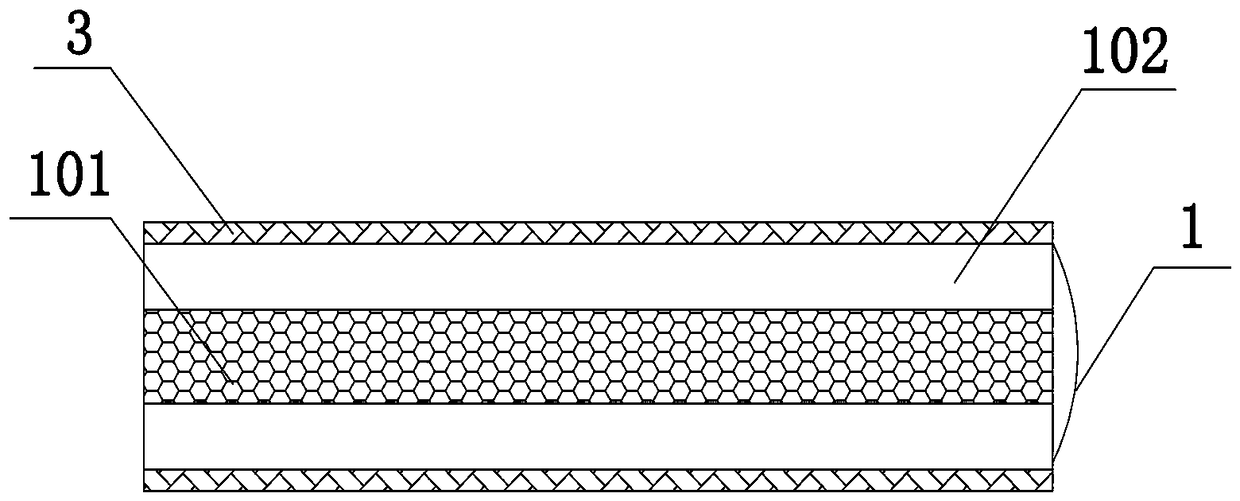

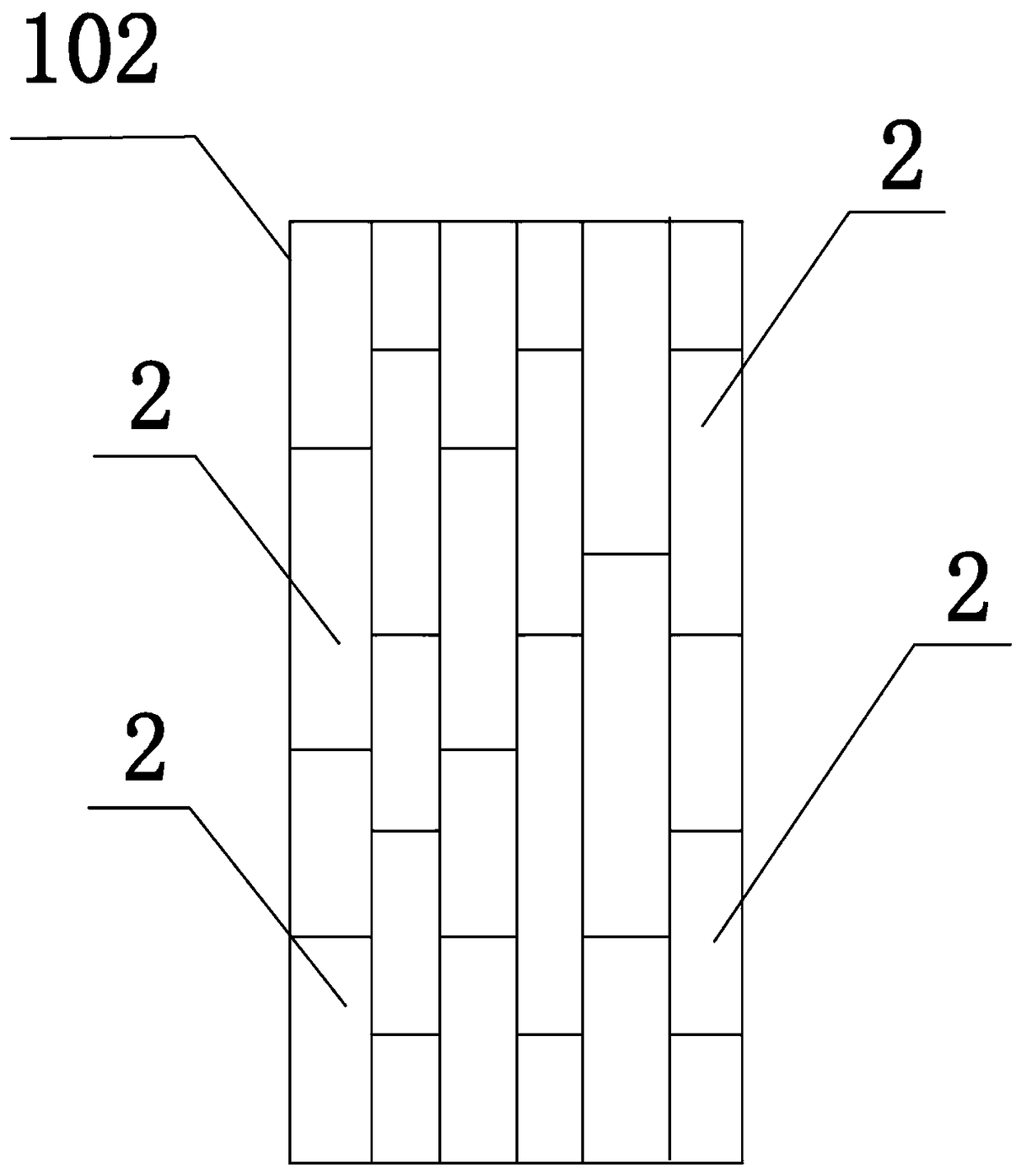

[0041] see figure 1 , this embodiment provides a multi-layer flame-retardant wood-based composite board, which has a five-layer structure, and specifically includes a set of flame-retardant sandwich panels 1, and the two sides of the flame-retardant sandwich panels are respectively provided with facing layers 3; The flame-retardant sandwich panel is composed of a layer of inorganic fireproof substrate layer 101 and wooden veneer layers 102 symmetrically arranged on both sides of the inorganic fireproof substrate layer; the inorganic fireproof substrate layer and the wooden veneer layer are water-soluble Bonded with flame retardant adhesive. Wherein, the veneer layer is wood chips with a thickness of 0.5 mm, and the substrate layer is a glass magnesium board with a thickness of 2 mm. see figure 2 , the wood veneer layer includes a plurality of wood boards 2, and the wood veneer layer is made of a plurality of wood boards with a thickness of 1.5 mm according to the actual siz...

Embodiment 2

[0053] This embodiment provides a multi-layer flame-retardant wood-based composite board, which has a 5-layer structure, and the structure is basically the same as the multi-layer flame-retardant wood-based composite board provided in the embodiment. The raw material composition is different. Specifically, in this example, magnesium sulfate 7 Kg, magnesium chloride 3 Kg, water 20 Kg, polyvinyl alcohol 1 Kg, boron phenol mixture 1.0 Kg, magnesium oxide 15 Kg, ammonium dihydrogen phosphate 0.15 Kg, ammonium polyphosphate 0.5 Kg , Calcium formate 0.1 Kg.

[0054] The preparation method of the above-mentioned multi-layer flame-retardant wood-based composite board provided in this example is basically the same as the preparation method of the multi-layer flame-retardant wood-based composite board provided in Example 1, except that the process parameters in the preparation steps are different. Specifically, in this embodiment, the number of slabs overlapped and stacked in the machi...

Embodiment 3

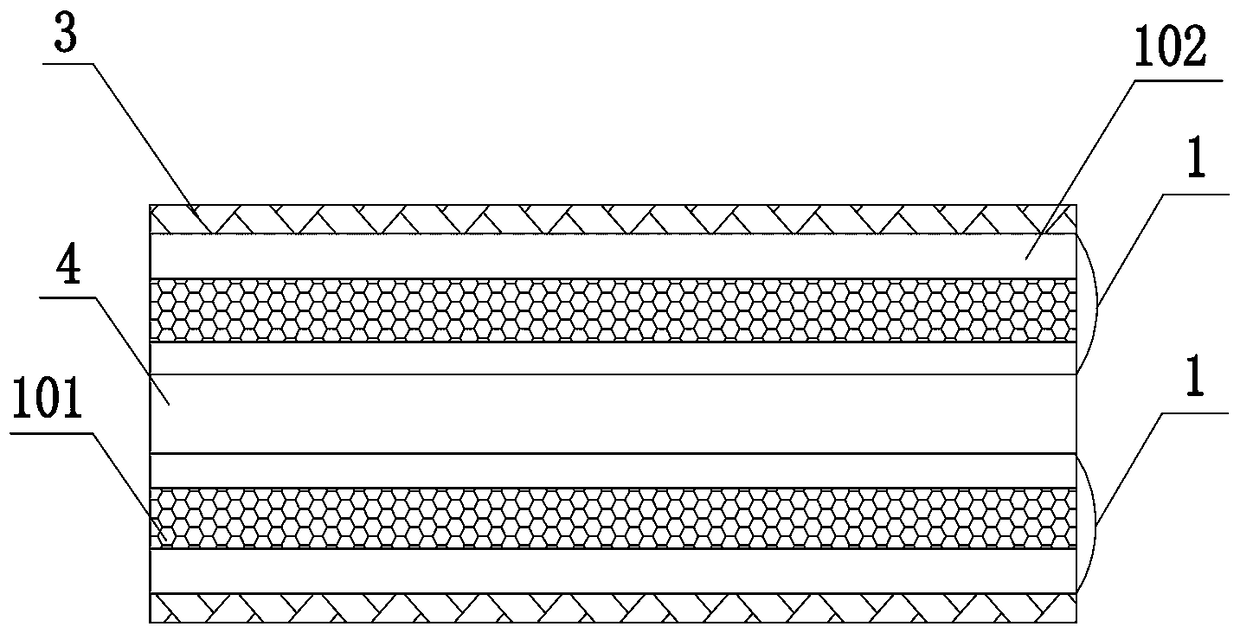

[0058] see image 3 , this embodiment provides a multi-layer flame-retardant wood-based composite board, which has a nine-layer structure. Specifically, the multi-layer fire-retardant wood-based composite board includes two sets of fire-retardant sandwich panels 1, and a core wood veneer layer 4 is also arranged between the two sets of fire-retardant sandwich panels; The face and bottom of the first-layer flame-retardant wood-based composite board are also provided with the said facing layer 3 respectively.

[0059] In this example, the raw material components in the water-soluble flame-retardant adhesive are the same as those in Example 1.

[0060] The preparation method of the above-mentioned multi-layer flame-retardant wood-based composite board provided in this example is basically the same as the preparation method of the multi-layer flame-retardant wood-based composite board provided in Example 1, the difference is: in the one-time combined molding step , two groups of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com