Method for preparing activated carbon with high specific surface area through rapid activation under fluidization

一种高比表面积、活性炭的技术,应用在化学仪器和方法、碳化合物、无机化学等方向,能够解决活化时间长、物料加热速率缓慢等问题,达到活化时间短、增加处理量、比表面积高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

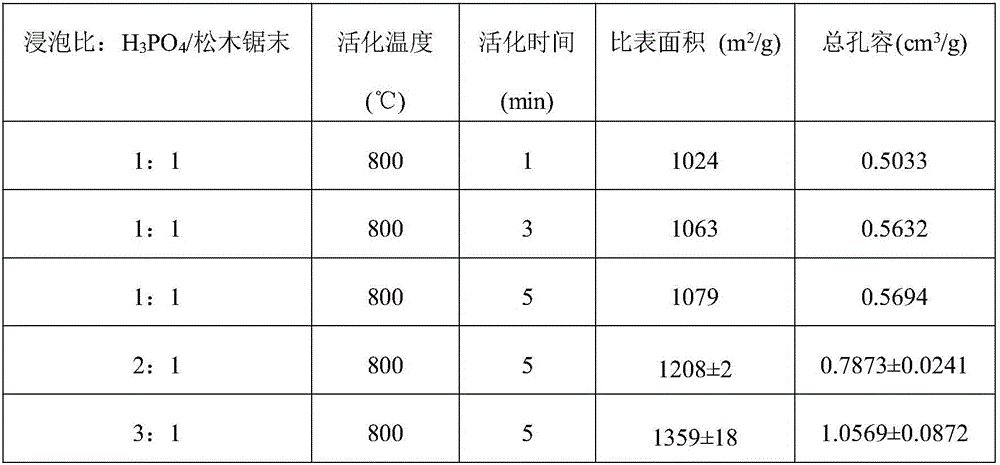

Embodiment 1

[0032] Mix and soak 85% phosphoric acid and pine sawdust, the material particle size is 0.56-0.9mm, the mass ratio of phosphoric acid and material is 1:1, 2:1, 3:1, soak at room temperature for 3 hours, and then put it in a constant temperature oven at 105°C Dry within 10h, then stir into granules. Activated in a spouted bed reactor, the activation temperature is 800°C, when the spouted bed reactor is heated up to 800°C, the fluidization gas nitrogen is introduced, and the immersion ratio (H 3 PO 4 / pine sawdust) is 1:1, 2:1, 3:1, the fluidizing gas volume of the fluidizing gas is 0.7m 3 / h, 1.5m 3 / h, 1.9m 3 / h, put 10g of granular material into the spouted bed reactor, and put 20g of quartz sand into it. Activation for 1-10min, after the activation, wash in warm water at 80°C until the pH is neutral. The following table is the quality parameters of activated carbon obtained by rapid activation of pine sawdust under fluidization. It can be concluded that the specific su...

Embodiment 2

[0036] Mix and soak 85% phosphoric acid and material walnut shells, the material particle size is 0.4-0.8mm, the mass ratio of phosphoric acid and material is 1.5:1 and 2:1, soak at room temperature for 3 hours, and then dry in a constant temperature oven at 105°C for 10 hours. Then stir until granulated. Activated in a spouted bed reactor, the activation temperature is 800°C, when the spouted bed reactor is heated up to 800°C, the fluidization gas nitrogen is introduced, and the immersion ratio (H 3 PO 4 / walnut shell) is 1.5:1, when 2:1, the fluidization gas volume of fluidization gas is 1.5m 3 / h, put 25g of quartz sand, put 10g of material into the spouted bed reactor, activate for 5min, wash in warm water at 80°C until the pH is neutral after activation.

[0037] The following table shows the quality of activated carbon prepared from walnut shells. It can also be concluded that under the phosphoric acid chemical activation method, high specific surface area activated ca...

Embodiment 3

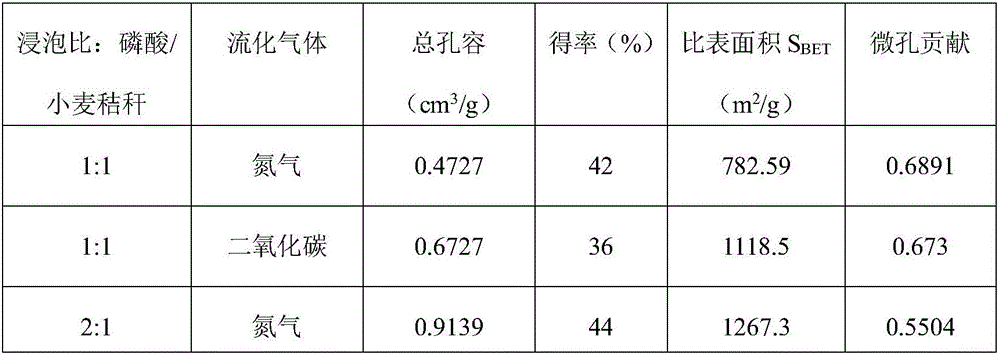

[0040] Mix and soak 85% phosphoric acid and wheat straw, the material particle size is 0.56-0.9mm, the soaking mass ratio of phosphoric acid and wheat straw is 1:1 and 2:1, soak for 3 hours at room temperature, and then dry in a constant temperature oven at 105°C After 10 hours, it was stirred into particles and activated in a spouted bed reactor at an activation temperature of 800°C. First heat the spouted bed reactor to 800°C, then feed fluidizing gas nitrogen or carbon dioxide, soaking ratio (H 3 PO 4 / wheat straw) is 1:1, 2:1, the fluidization gas volume of fluidization gas is 0.7m 3 / h, 1.5m 3 / h, put 30g of quartz sand, put 10g of material into the spouted bed reactor, activate for 5min, quickly pour out the material after activation, and wash in warm water at 80°C until the pH is neutral.

[0041] The following table is the quality parameters of the obtained activated carbon. It can be seen that even if the activation time is only 5 minutes, the specific surface ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com