Fe3O4/CNTs-based synergic microwave organic pesticide degradation method

A technology of organic pesticides and synergistic microwaves, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of incomplete degradation, secondary pollution, etc. High degradation efficiency and the effect of improving the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

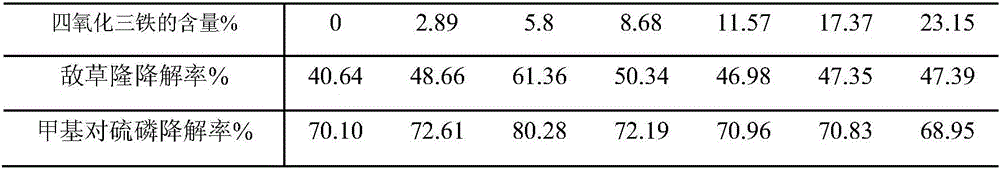

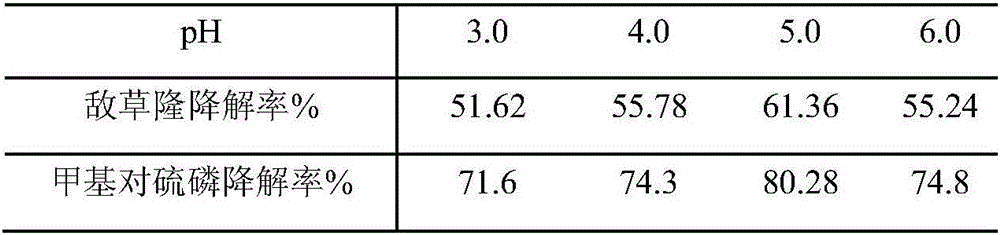

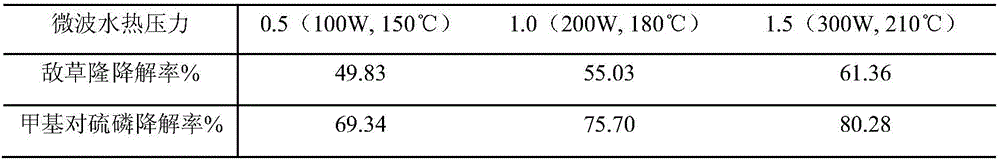

[0014] The influence of embodiment 1 catalyst on degradation organic pesticide

[0015] Pretreatment of carbon nanotube CNTs: accurately weigh 5.0 g of carbon nanotube CNTs (20-40 nm) powder, put it into 300 mL of 2.0 mol / L nitric acid solution, and boil at 100 ° C for 30 min. Cool to room temperature, filter, wash with deionized water several times until pH = 7, filter, dry in a vacuum drying oven at 105°C for 6.0 h, grind to obtain purified CNTs powder, store in a desiccator for future use.

[0016] Fe 3 o 4 Supported carbon nanotube nanoparticles Fe 3 o 4 / CNTs preparation: Ultrasonic dispersion of pretreated carbon nanotubes CNTs in deionized water, ultrasonic treatment for 15min, a certain amount of Fe(NO 3 ) 3 9H 2 O was added to the mixed solution, and ultrasonically treated for 20 minutes, and NaAc was added to adjust the pH of the solution to 2.5-6.0, and ultrasonicated for 15 minutes, then the mixed solution was added to a polytetrafluoroethylene autoclave, sea...

Embodiment 2

[0036] The method of embodiment 2 degradation organic pesticide methyl parathion

[0037] Pretreatment of carbon nanotube CNTs: accurately weigh 5.0g of carbon nanotube CNTs (20-40nm) powder, put it into 300mL, 2.0mol / L nitric acid solution, and boil at 100°C for 30min. Cool to room temperature, filter, wash with deionized water several times until pH = 7, filter, dry in a vacuum drying oven at 105°C for 6.0 h, grind to obtain purified CNTs powder, store in a desiccator for future use.

[0038] Fe 3 o 4 Supported carbon nanotube nanoparticles Fe 3 o 4 / CNTs preparation: Ultrasonic dispersion of pretreated carbon nanotubes CNTs in deionized water, ultrasonic treatment for 15min, a certain amount of Fe(NO 3 ) 3 9H 2 O was added to the mixed solution, and ultrasonically treated for 20 minutes, and NaAc was added to adjust the pH of the solution to 5.0, and ultrasonicated for 15 minutes. Pressure 1.5MPa, microwave 300W, temperature 210°C, microwave irradiation for 30min, ta...

Embodiment 3

[0054] Embodiment 3 comparative experiment

[0055] Prepared by co-precipitation method: 0.4g of purified carbon nanotubes (CNTs) were ultrasonically dispersed in 15mL of deionized water, and ultrasonically treated for 10min to form a stable suspension. A certain amount of Fe(NO 3 ) 3 9H 2 O (M=404.02) was added to the mixed solution, and ultrasonic treatment was performed for 15 minutes. Add NaAc to adjust the pH of the solution to 5.0, sonicate for 10 minutes, raise the temperature to 95°C while stirring, and maintain it for 60 minutes. The mixture was filtered, washed several times with deionized water, and dried in an oven at 180 °C for 2 h. Calcined at 250°C for 6h after taking out, cooling and grinding after taking out.

[0056] Prepared by hydrothermal method: 0.4g purified carbon nanotubes CNTs were ultrasonically dispersed in 15mL deionized water, and treated ultrasonically for 10min. A certain amount of Fe(NO 3 ) 3 9H 2 O (M=404.02) was added to the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com