Purifying salt production system and method for synchronous removal of organic matters through evaporative crystallization of high-salinity organic wastewater

A technology of organic waste water and evaporative crystallization, which is applied in evaporative separation crystallization, chemical instruments and methods, crystallization separation, etc., can solve the problem of inability to obtain crystalline salt, and achieve the effects of compact structure, water saving and pollution elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

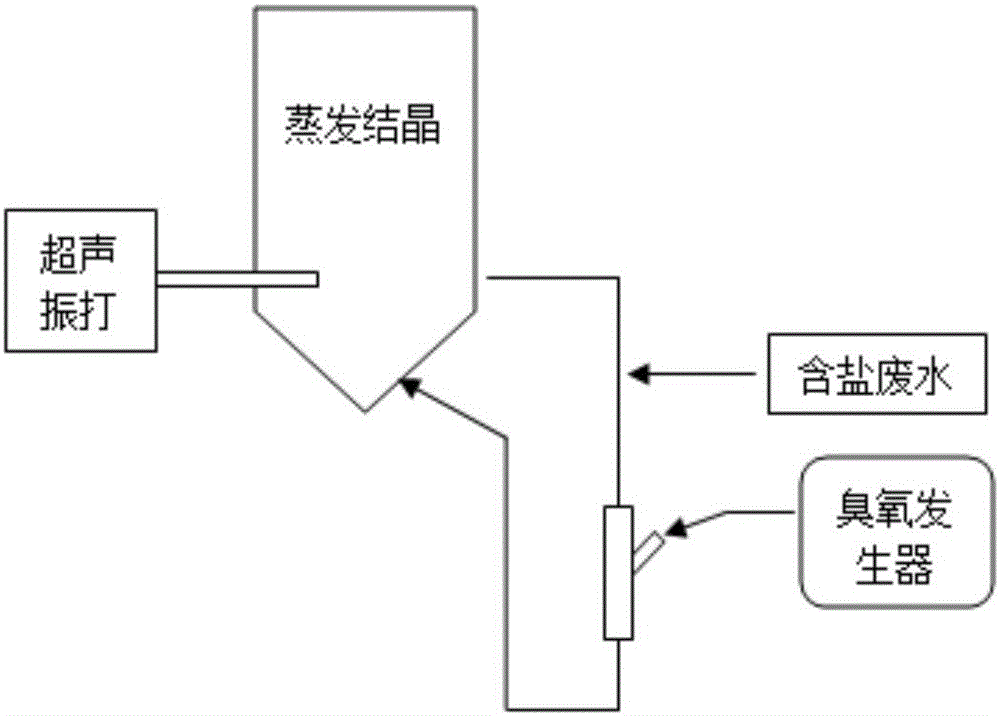

[0036] The high-salt organic wastewater evaporation and crystallization in this example is a purified salt-making system that simultaneously removes organic matter, such as figure 1 shown, including:

[0037] evaporative crystallizer;

[0038] A material circulation pipe connected to the evaporative crystallizer;

[0039] and an oxidation treatment reactor arranged on the material circulation pipe; the oxidation treatment reactor is an ozone oxidation reactor;

[0040] And the high-frequency ultrasonic rapping device arranged at the lower side of the evaporation crystallizer; the ultrasonic rapping device is an ultrasonic vibrating rod.

[0041] The method for purifying and producing salt by evaporating and crystallizing high-salt organic wastewater according to the present invention to simultaneously remove organic matter comprises:

[0042] 1) High-salt organic wastewater enters the evaporation crystallizer through the material circulation pipe; the COD of the saline wast...

Embodiment 2

[0049] The high-salt organic wastewater evaporation and crystallization in this example is a purified salt-making system that simultaneously removes organic matter, such as figure 1 shown, including:

[0050] evaporative crystallizer;

[0051] The material circulation pipe connected with the evaporative crystallizer;

[0052] and an oxidation treatment reactor arranged on the material circulation pipe; the oxidation treatment reactor is an ozone oxidation reactor;

[0053] and the ultrasonic vibrating device arranged at the lower side of the evaporation crystallizer; the ultrasonic vibrating device is an ultrasonic vibrating rod.

[0054] The method for purifying and producing salt by evaporating and crystallizing high-salt organic wastewater according to the present invention to simultaneously remove organic matter comprises:

[0055] 1) High-salt organic wastewater enters the evaporation crystallizer through the material circulation pipe; the COD of salty wastewater is 20...

Embodiment 3

[0062] The high-salt organic wastewater evaporation and crystallization in this example is a purified salt-making system that simultaneously removes organic matter, such as figure 1 shown, including:

[0063] evaporative crystallizer;

[0064] The material circulation pipe connected with the evaporative crystallizer;

[0065] and an oxidation treatment reactor arranged on the material circulation pipe; the oxidation treatment reactor is an ozone oxidation reactor;

[0066] and the ultrasonic vibrating device arranged at the lower side of the evaporation crystallizer; the ultrasonic vibrating device is an ultrasonic vibrating rod.

[0067] The method for purifying and producing salt by evaporating and crystallizing high-salt organic wastewater according to the present invention to simultaneously remove organic matter comprises:

[0068] 1) High-salt organic wastewater enters the evaporation crystallizer through the material circulation pipe; the salt-containing wastewater CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com