Ultrasonic catalyzed cross-linking-cellulose filter-pressing separation system

A separation system and ultrasonic technology, applied in the fields of filtration treatment, chemical instruments and methods, processing wastewater treatment, etc., can solve the problems of unsatisfactory treatment effect, complicated process and equipment, large equipment investment and floor space, etc. Conducive to large-scale promotion and application, saving subsequent processing costs, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

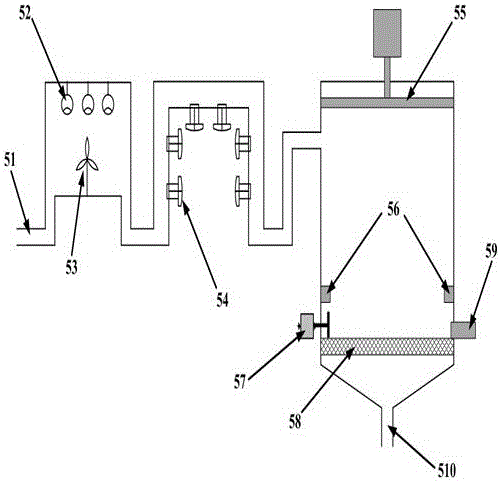

[0024] Such as figure 1As shown, ultrasonic catalyzed crosslinking-cellulose pressure filtration separation system, ultrasonic catalysis crosslinking-cellulose pressure filtration separation system 5 is composed of three parts: dosing premixing area, ultrasonic catalysis crosslinking reaction area and pressure filter tank. The front end is provided with a water inlet valve 51, and the water inlet valve 51 is connected to the dosing premixing area through a pipeline. There are three dosing nozzles 52 on the top of this area, and one stirring blade 53 is installed in the middle, and the dosing premixing area It is connected to the ultrasonic catalytic cross-linking reaction area through pipelines. Six ultrasonic generators 54 are installed side by side in this area. The ultrasonic catalytic cross-linking reaction area is connected to the pressure filter tank through pipelines. Piston type filter press device 55, a piston stopper 56 is installed on the left and right sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com