Wide-temperature-range high-frequency low-loss magnetic material and preparing technology thereof

A magnetic material and low-loss technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve problems such as inability to guarantee mass production, and achieve low initial magnetic permeability, good wide temperature characteristics, good high frequency and low power loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

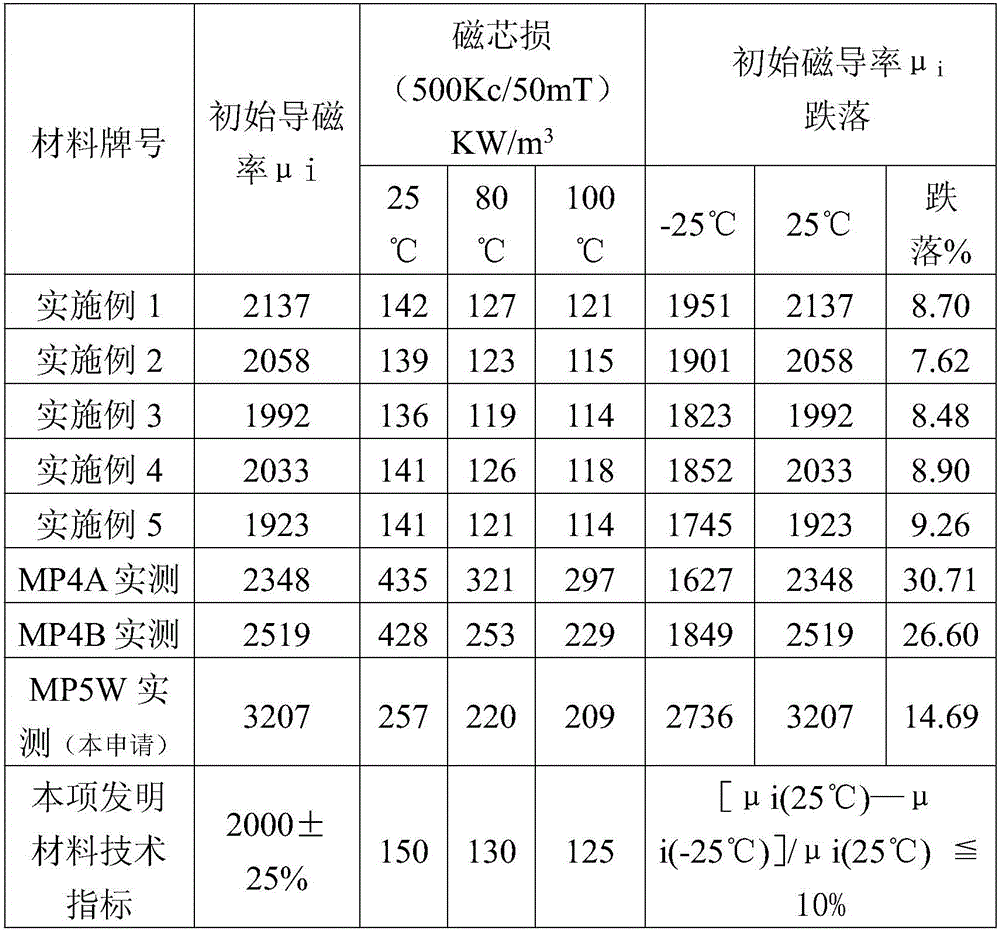

Examples

Embodiment 1

[0028] A wide-temperature, high-frequency, low-loss magnetic material of the present invention, the formula of the material is composed of three main raw materials of iron oxide, manganese tetraoxide and zinc oxide to form a basic formula, and several additives are added on this basis. The formula consists of The scope is as follows:

[0029] Iron oxide (Fe 2 o 3 ): 69.93g;

[0030] Trimanganese tetraoxide (Mn 3 o 4 ): 23.9g;

[0031] Zinc oxide (ZnO): 6.4g;

[0032] Silicon dioxide (SiO 2 ): 0.005g;

[0033] Calcium Carbonate (CaCO 3 ): 0.04g;

[0034] Cobalt tetroxide (Co 3 o 4 ): 0.36g;

[0035] Phosphorus pentoxide (P 2 o 5 ): 0.002g;

[0036] Tin dioxide (SnO 2 ): 0.1g;

[0037] Sodium bicarbonate (NaHCO 3 ): 0.01g;

[0038] Zirconia (ZrO 2 ): 0.02g;

[0039] Titanium dioxide (TiO 2 ): 0.2g;

[0040] Tantalum pentoxide (Ta 2 o 5 ): 0.015g.

[0041] A preparation process for a wide temperature, high frequency, low loss magnetic material. First, th...

Embodiment 2

[0043] A wide-temperature, high-frequency, low-loss magnetic material of the present invention, the formula of the material is composed of three main raw materials of iron oxide, manganese tetraoxide and zinc oxide to form a basic formula, and several additives are added on this basis. The formula consists of The scope is as follows:

[0044] Iron oxide (Fe 2 o 3 ): 70.31g;

[0045] Trimanganese tetraoxide (Mn 3 o 4 ): 23.87g;

[0046] Zinc oxide (ZnO): 6.12g;

[0047] Silicon dioxide (SiO 2 ): 0.006g;

[0048] Calcium Carbonate (CaCO 3 ): 0.05g;

[0049] Cobalt tetroxide (Co 3 o 4 ): 0.45g;

[0050] Phosphorus pentoxide (P 2 o 5 ): 0.003g;

[0051] Tin dioxide (SnO 2 ): 0.15g;

[0052] Sodium bicarbonate (NaHCO 3 ): 0.01g;

[0053] Zirconia (ZrO 2 ): 0.023g;

[0054] Titanium dioxide (TiO 2 ): 0.15g;

[0055] Tantalum pentoxide (Ta 2 o 5 ):0.02g;

[0056] Molybdenum trioxide (MoO 3 ): 0.02g.

[0057] A preparation process for a wide temperature, hi...

Embodiment 3

[0059] A wide-temperature, high-frequency, low-loss magnetic material of the present invention, the formula of the material is composed of three main raw materials of iron oxide, manganese tetraoxide and zinc oxide to form a basic formula, and several additives are added on this basis. The formula consists of The scope is as follows:

[0060] Iron oxide (Fe 2 o 3 ): 70.60g;

[0061] Trimanganese tetraoxide (Mn 3 o 4 ): 24.0g;

[0062] Zinc oxide (ZnO): 4.92g;

[0063] Silicon dioxide (SiO 2 ): 0.007g;

[0064] Calcium Carbonate (CaCO 3 ): 0.055g;

[0065] Cobalt tetroxide (Co 3 o 4 ): 0.35g;

[0066] Phosphorus pentoxide (P 2 o 5 ): 0.005g;

[0067] Tin dioxide (SnO 2 ): 0.12g;

[0068] Zirconia (ZrO 2 ): 0.03g;

[0069] Titanium dioxide (TiO 2 ): 0.19g;

[0070] Tantalum pentoxide (Ta 2 o 5 ):0.015g;

[0071] Molybdenum trioxide (MoO 3 ): 0.02g.

[0072] A preparation process for a wide temperature, high frequency, low loss magnetic material. First, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com