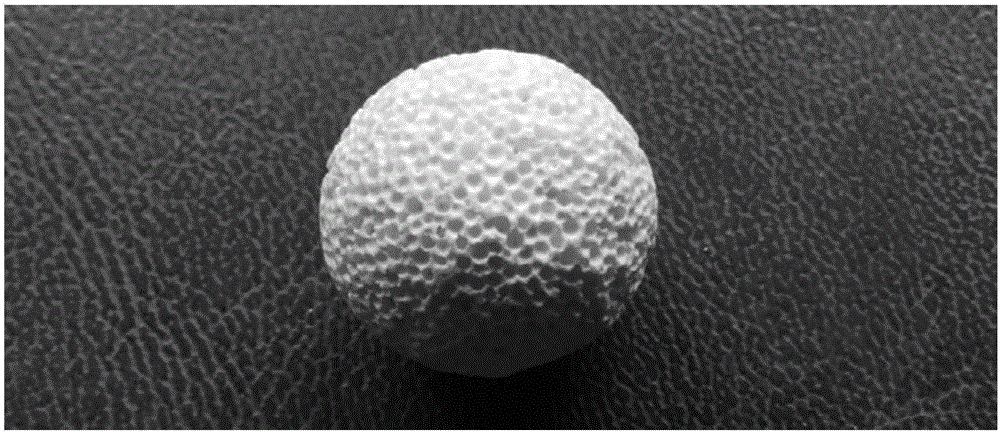

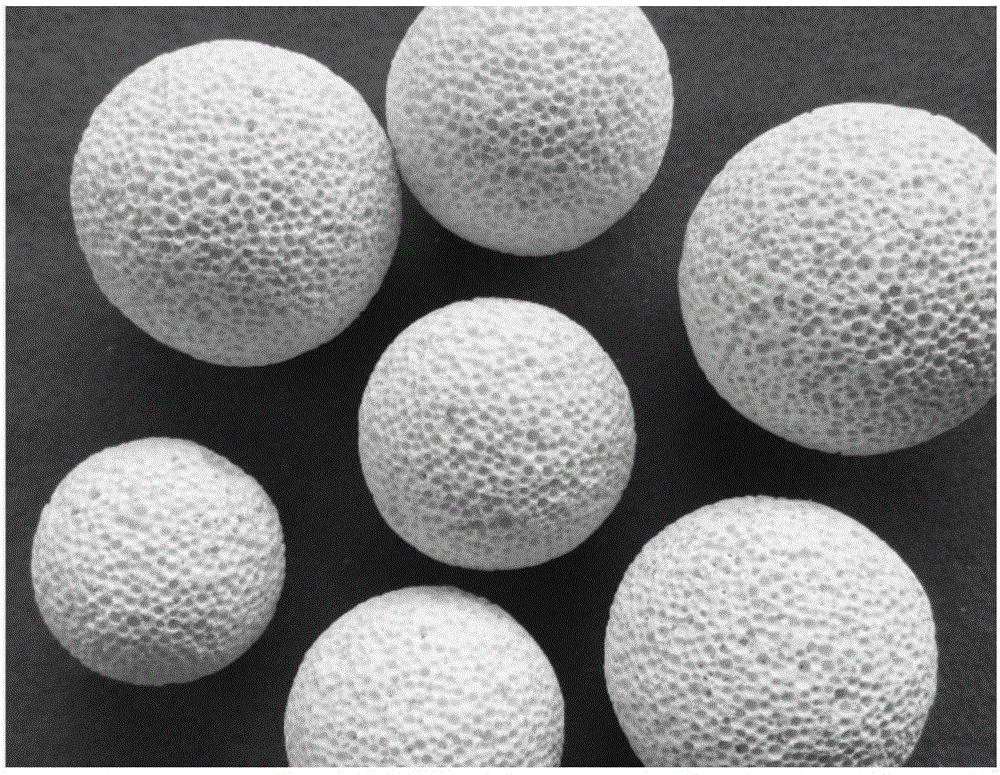

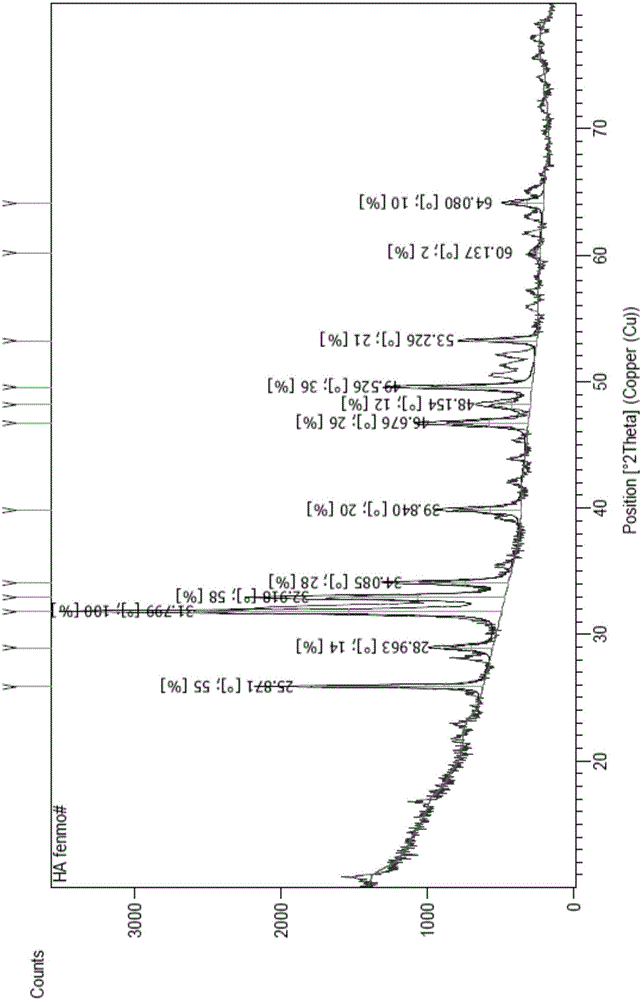

Method for manufacturing porous hydroxyapatite orbital implant

A technology for hydroxyapatite and a manufacturing method, which is applied in ceramic products, applications, medical science and other directions, can solve the problems affecting the biological activity and biocompatibility of hydroxyapatite, the prosthetic eye seat has no pores, and the manufacturing process is complicated. , to achieve the effect of adjustable apparent density, controllable porosity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take the production of 80 grams of hydroxyapatite powder raw material as an example:

[0035] Weigh 107.1 g (NH) 2 HPO 4 , dissolved in 2000 ml deionized water, add 1150 ml concentrated NH 4 OH, measured pH ≈ 12, add deionized water to 4850 ml.

[0036] Weigh 319.2 g Ca(NO 3 ) 2 Dissolve in 1200 ml of deionized water, add 50 ml of concentrated NH 4 OH, measured pH ≈ 12, add deionized water to 2400 ml.

[0037] Under rapid stirring with a stirrer, the (NH) 2 HPO 4 The solution was slowly dripped into Ca(NO 3 ) 2 During the synthesis reaction, the solution was continuously stirred for more than 24 hours for aging treatment, and then centrifugally cleaned with a centrifuge.

[0038] The speed of the centrifuge is 4000 rpm. After centrifuging for about 7 minutes, take out the colloidal sediment and add deionized water to stir evenly, and then perform the next centrifugal cleaning until the pH value of the upper layer of centrifuged separation is PH≈7.

[0039] St...

Embodiment 2

[0043] Prepare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 dilute solution, add NH 4 OH to adjust the solution to pH 10 respectively, under rapid stirring, the (NH) 2 HPO 4 The solution was slowly dropped into Ca(NO 3 ) 2 Synthesis reaction in solution. Continuous stirring for 24 hours for aging treatment, centrifugal cleaning, until the upper water of centrifugal separation is neutral, degassing treatment in a vacuum drying oven at 100°C with a negative pressure of 100mmHg to eliminate fine air bubbles and adsorption in the colloidal sediment Gas, to obtain colloidal precipitation of hydroxyapatite with high interfacial free energy composed of a large amount of hydroxyapatite amorphous state, crystal nuclei and microcrystals.

[0044] The colloidal precipitate of hydroxyapatite is dried and treated at a low temperature of 300°C to obtain colloidal aggregates of hydroxyapatite; after cooling, it is then ground to produce hydroxyapatite with a particle size of 20-60 μm and higher ...

Embodiment 3

[0048] Prepare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 dilute solution, add NH 4 OH to adjust the solution to pH 12 respectively, under rapid stirring, the (NH) 2 HPO 4 The solution was slowly dropped into Ca(NO 3 ) 2 Synthesis reaction in solution. Continuous stirring for 10 hours for aging treatment, centrifugal cleaning, until the upper water of centrifugal separation is neutral, degassing treatment in a vacuum drying oven at 40°C with a negative pressure of 400mmHg to eliminate fine air bubbles and adsorption in the colloidal sediment Gas, to obtain colloidal precipitation of hydroxyapatite with high interfacial free energy composed of a large amount of hydroxyapatite amorphous state, crystal nuclei and microcrystals.

[0049] Hydroxyapatite colloidal precipitates are dried and treated at a low temperature of 200°C to obtain hydroxyapatite colloidal aggregates; after cooling, they are then ground to produce hydroxyphosphorus with a particle size of 20-60 μm and higher int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com