Preparation method of organic ferroelectric film with high polarization intensity

A technology of polarization strength and thin film preparation, applied in the field of organic ferroelectric polymer materials, can solve the problems of no improvement in electrical properties, and achieve the effects of easy process control, excellent electrical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) The ITO substrate was ultrasonically cleaned in deionized water, acetone, and absolute ethanol in sequence, and then dried by infrared lamps;

[0023] 2) Dissolve 1 g of PVDF-TrFE in 20 mL of tetrahydrofuran to obtain a tetrahydrofuran solution of PVDF-TrFE;

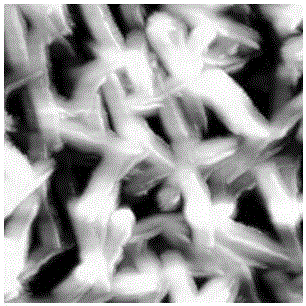

[0024] 3) Add 0.002g of PbTiO 3 nanosheets placed in the solution obtained in step 2), PbTiO 3 The mass / volume ratio of the tetrahydrofuran solution of nanosheets and PVDF-TrFE is 0.2%, and stirred to obtain a suspension;

[0025] 4) Ultrasonic treatment of the suspension obtained in step 3) to make PbTiO 3 The nanosheets were uniformly dispersed in PVDF-TrFE solution in tetrahydrofuran, and after standing for 20 min, it was spin-coated (1500 rpm, 30 s) onto a clean ITO substrate to obtain a thin film;

[0026] 5) The film obtained in step 4) was vacuum-dried and heat-treated at 180° C. for 1 hour.

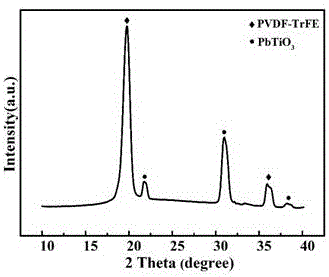

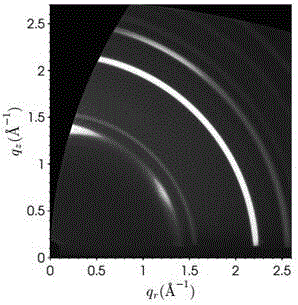

[0027] The thickness of the organic ferroelectric film prepared in this example is 0.8 μm, and its grazing i...

Embodiment 2

[0029] The specific process steps are the same as in Example 1, the difference is that the PbTiO taken in step 3) 3 Nanosheets are 0.005g , PbTiO 3 The mass / volume ratio of nanosheets to PVDF-TrFE in tetrahydrofuran solution was 0.5%, the resting time in step 4) was 40 min, and the heat treatment time in step 5) was 0.5 h. The remanent polarization of the organic ferroelectric thin film prepared in this example is 10μC / cm 2 .

Embodiment 3

[0031] The specific process steps are the same as in Example 1, the difference is that the Si substrate is used, and the PbTiO taken in step 3) is 3 Nanosheets are 0.0527g , PbTiO 3 The mass / volume ratio of nanosheets and PVDF-TrFE in tetrahydrofuran solution is 5.0%, step 4) standing time is 30 min, and step 5) heat treatment time is 2 hours, the remanent polarization of the organic ferroelectric thin film prepared in this example 8μC / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com