Multifunctional power maintenance safety protection glove material

A safety protection and multi-functional technology, applied in the field of electric power, can solve the problems of short service life and poor effect of gloves, and achieve the effect of superior flame retardant and improved product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

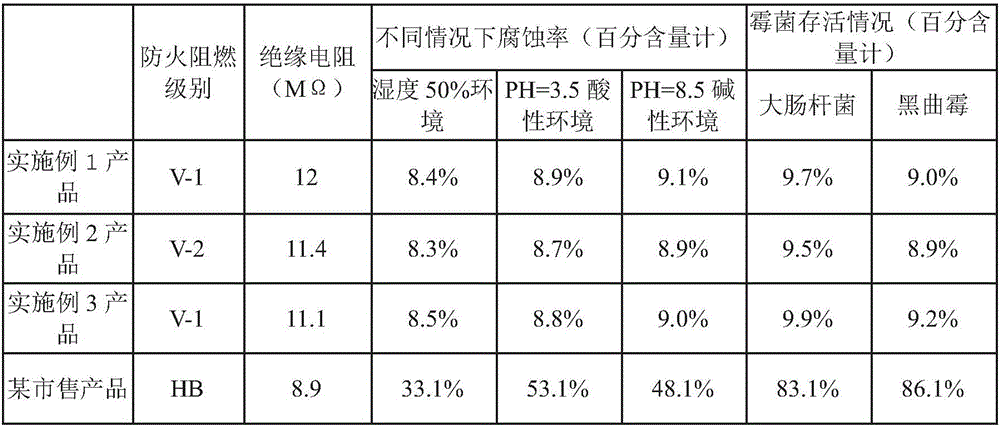

Embodiment 1

[0016] The multifunctional power maintenance safety protective glove material in this embodiment is composed of the following components in parts by mass: 24 parts of polyisoprene, 22 parts of furfuryl alcohol resin, 22 parts of chlorohydrin rubber, 20 parts of polyacrylic acid emulsion, poly 22 parts of glycerin ricinoleate, 22 parts of polyethylene wax emulsion, 20 parts of rose essential oil, 22 parts of grape seed oil, 22 parts of ethyl p-hydroxybenzoate, 20 parts of oxazolidinone, tetramethyl qiuran disulfide 20 parts of molasses, 20 parts of dibromomethane, 22 parts of aluminum silicate fiber, 20 parts of sodium silicate powder, 18 parts of Portland cement, 22 parts of diatom mud, 20 parts of siliceous shale powder, 18 parts of conch shell powder, 20 parts of sepiolite powder, 18 parts of seaweed mud, 18 parts of pyromellitic dianhydride, 20 parts of tricresyl phosphate, 20 parts of hexahydrophthalic anhydride, 20 parts of triethylene glycol diisocaprylate, 20 parts of t...

Embodiment 2

[0022] The multifunctional power maintenance safety protective glove material in this embodiment is composed of the following components in parts by mass: 26 parts of polyisoprene, 24 parts of furfuryl alcohol resin, 24 parts of chlorohydrin rubber, 22 parts of polyacrylic acid emulsion, poly 24 parts of glycerin ricinoleate, 24 parts of polyethylene wax emulsion, 22 parts of rose essential oil, 24 parts of grape seed oil, 24 parts of ethyl p-hydroxybenzoate, 22 parts of oxazolidinone, tetramethyl qiuran disulfide 22 parts of molasses, 22 parts of dibromomethane, 24 parts of aluminum silicate fiber, 22 parts of sodium silicate powder, 20 parts of Portland cement, 24 parts of diatom mud, 22 parts of siliceous shale powder, 20 parts of conch shell powder, 22 parts of sepiolite powder, 20 parts of seaweed mud, 20 parts of pyromellitic dianhydride, 22 parts of tricresyl phosphate, 22 parts of hexahydrophthalic anhydride, 22 parts of triethylene glycol diisocaprylate, 22 parts of t...

Embodiment 3

[0028] The multifunctional power maintenance safety protective glove material in this embodiment is composed of the following components in parts by mass: 28 parts of polyisoprene, 26 parts of furfuryl alcohol resin, 26 parts of chlorohydrin rubber, 24 parts of polyacrylic acid emulsion, poly 26 parts of glycerin ricinoleate, 26 parts of polyethylene wax emulsion, 24 parts of rose essential oil, 26 parts of grape seed oil, 26 parts of ethyl p-hydroxybenzoate, 24 parts of oxazolidinone, tetramethyl qiuran disulfide 24 parts of molasses, 24 parts of dibromomethane, 26 parts of aluminum silicate fiber, 24 parts of sodium silicate powder, 22 parts of Portland cement, 26 parts of diatom mud, 24 parts of siliceous shale powder, 22 parts of conch shell powder, 24 parts of sepiolite powder, 22 parts of seaweed mud, 22 parts of pyromellitic dianhydride, 24 parts of tricresyl phosphate, 24 parts of hexahydrophthalic anhydride, 24 parts of triethylene glycol diisocaprylate, 24 parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com