Anticorrosive and conductive coating and preparation method thereof

A coating and coating technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of electrical conductivity, oil resistance, water resistance, oil resistance and non-conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

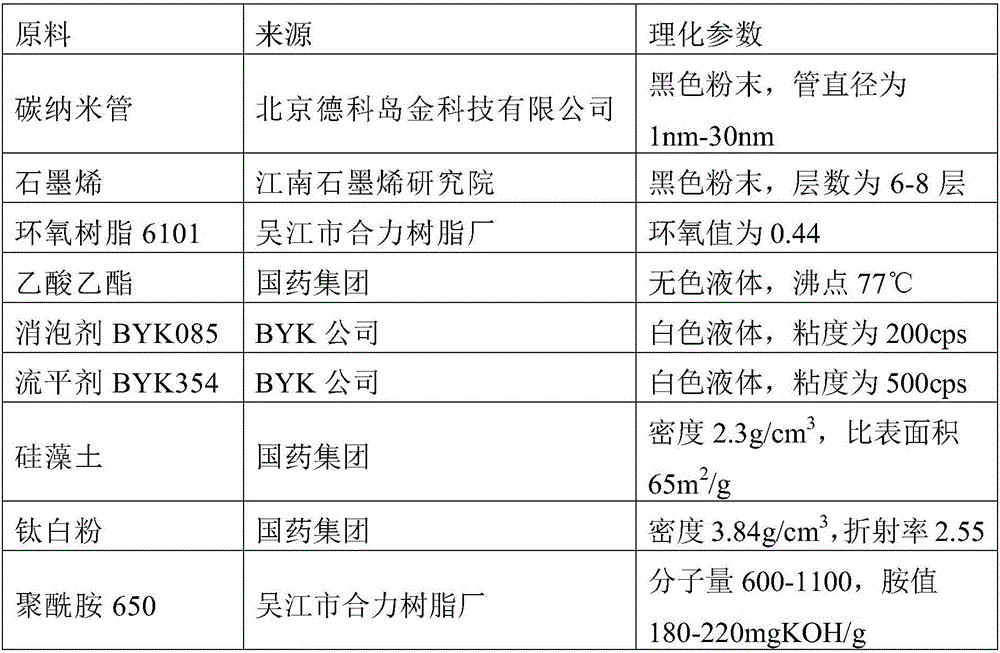

[0092] Example 1 - Coating 1

[0093] Disperse 0.03g of pyrogallol, 0.1g of carbon nanotubes, and 0.2g of graphene powder in 1.2L of tetrahydrofuran, ultrasonicate for 1.5 hours, add the resulting dispersion slurry to 100g of epoxy resin 6101, and then add 20mL of acetic acid in sequence Ethyl ester, 10mL xylene, 0.1g BYK085, 0.1g BYK354, 0.3g diatomaceous earth, 5.0g titanium dioxide and 10.0g barium sulfate, stirred at 1500r / min for 30min, then added 90g of polyamide 650, stirred evenly to obtain The coating 1.

[0094] result:

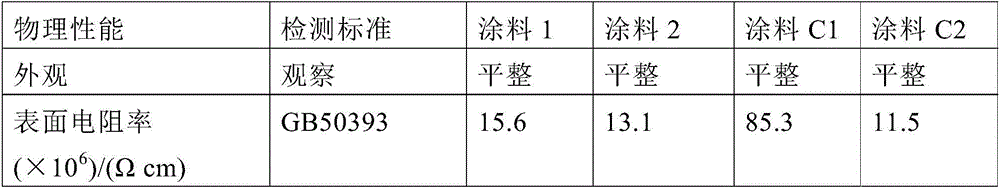

[0095] According to GB50393, GB / T 1732, ASTM-B117, GB1763, GB9274, the results are shown in Table 2 below. The surface resistivity, impact strength, salt spray resistance, salt water resistance and acid and alkali resistance of coating 1 are all meet the requirements.

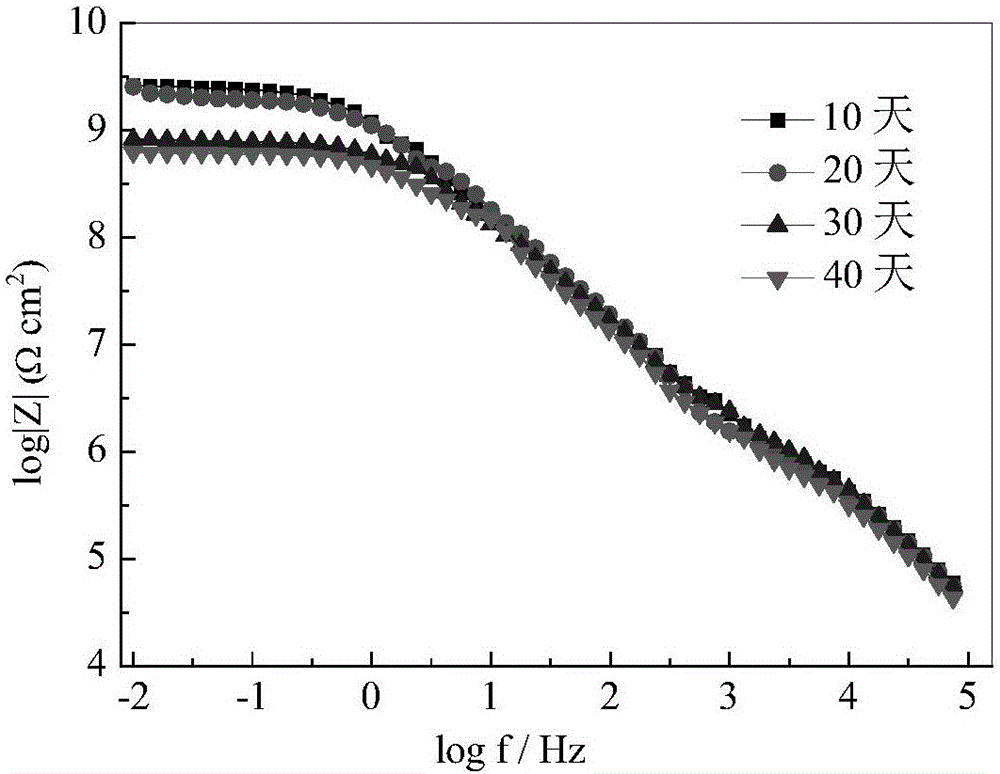

[0096] Coating 1 is coated on the Q235 carbon steel, soaked in the 3.5%NaCl solution for different time AC impedance spectrograms see figure 1 , the low-frequency impedance modul...

Embodiment 2-

[0097] Example 2 - Coating 2

[0098] With embodiment 1, difference is:

[0099] Disperse 0.02g of pyrogallol, 0.15g of carbon nanotubes, and 0.15g of graphene powder in 1.0L of acetone, 0.4g of diatomaceous earth, 6.0g of titanium dioxide, 11.0g of barium sulfate, and 11.0g of polyamide 650 80g, the coating 2 can be obtained.

[0100] result:

[0101] According to GB50393, GB / T 1732, ASTM-B117, GB1763, GB9274, the results are shown in Table 2 below. The surface resistivity, impact strength, salt spray resistance, salt water resistance and acid and alkali resistance of coating 2 are all meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com