A kind of graphene type anti-radiation coating

A technology of anti-radiation coatings and graphene, applied in the field of anti-radiation coatings, can solve the problems of increased coating costs, more graphene, and difficult large-scale application of products, and achieve reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of graphene type anti-radiation coating

[0036] 1. Take resin, wave-absorbing filler, graphene, surfactant and solvent by weight ratio in Table 1;

[0037] 2. Mix the above materials to obtain a mixed solution, and stir in a double planetary mixer for 50-60 minutes, so that the graphene is evenly coated on the outer periphery of the wave-absorbing filler;

[0038] 3. The mixed solution obtained in step 2 is filtered, and vacuum defoaming is made into a graphene-type anti-radiation coating.

[0039] In this example,

[0040] The resin is polyurethane resin R-961;

[0041] The wave-absorbing filler is made of wave-absorbing particles, and the wave-absorbing particles are made of FeSiAl wave-absorbing particles;

[0042] Graphene is graphene powder with 4-8 carbon layers;

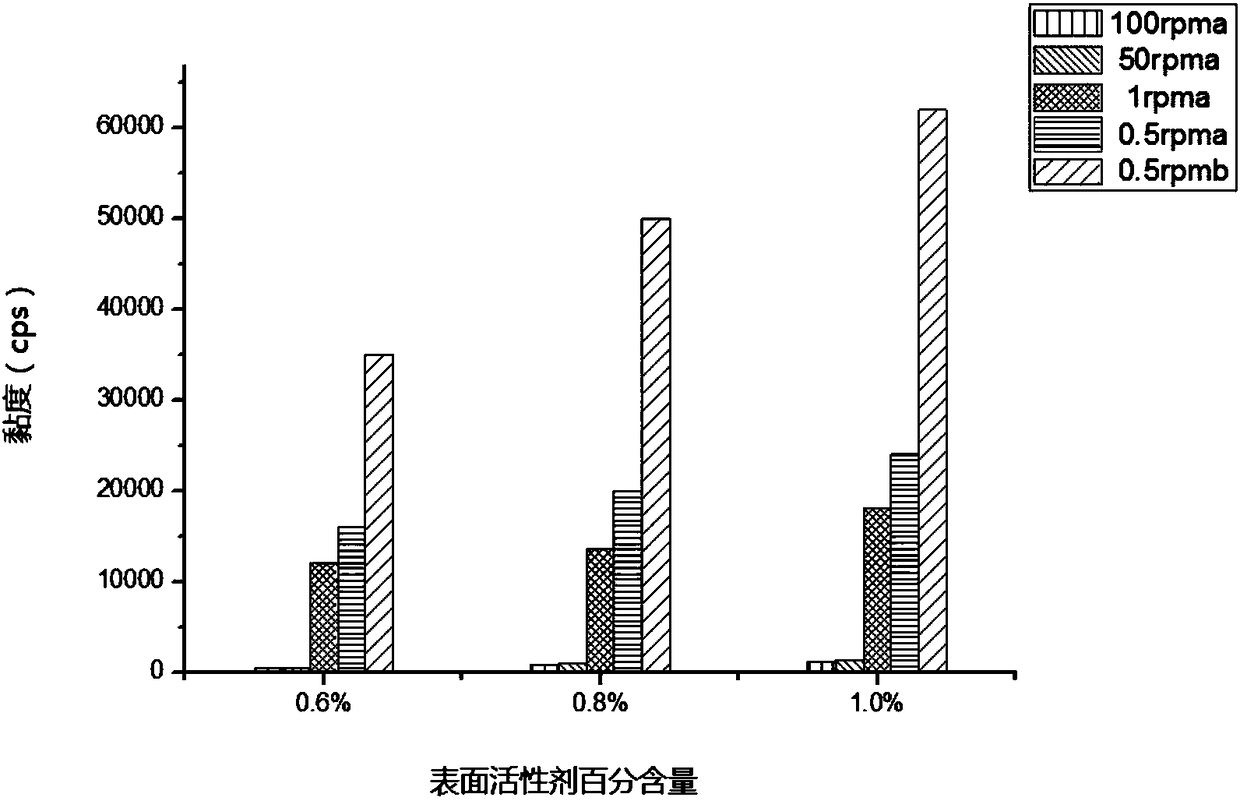

[0043] The surfactant is BYK420;

[0044] The solvent is water.

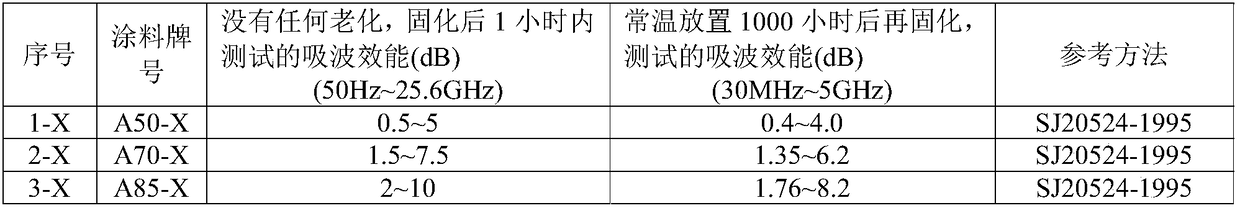

[0045] Table 1

[0046] serial number

Paint grade

Absorbing filler

Graphene powder

resin

...

Embodiment 2

[0051] Preparation of graphene type anti-radiation coating

[0052] 1. Take resin, wave-absorbing filler, surface treatment agent, surfactant and solvent according to the weight ratio in Table 3;

[0053] 2. Put the wave-absorbing filler in the vibrating sieve; the vibrating sieve vibrates at a frequency of 70 Hz, and drip the surface treatment agent while vibrating; mix the wave-absorbing filler and the surface treatment agent evenly, and then place it in an oven at 120 degrees to bake Bake for 1 hour to obtain the wave-absorbing stuffing with coating;

[0054] 3. Mix the coated wave-absorbing filler, resin, surfactant and solvent obtained in step 2, and stir in a double planetary mixer for 50-60 minutes to obtain a uniformly mixed mixture;

[0055] 4. The mixed solution that step 3 is obtained is filtered, and vacuum defoaming is made into graphene type anti-radiation coating.

[0056] In this example,

[0057] The resin is polyurethane resin R-961;

[0058] The wave-absor...

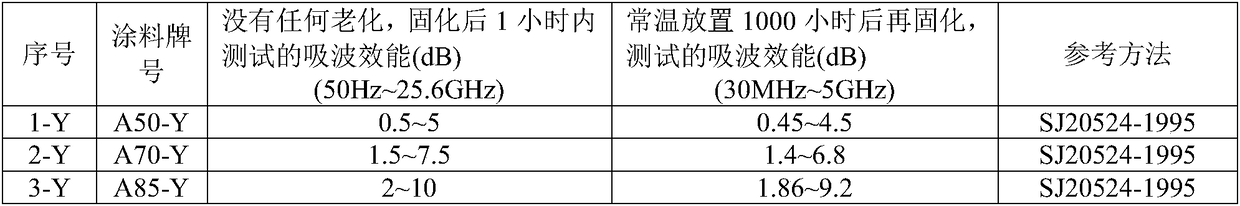

Embodiment 3

[0068] Preparation of graphene type anti-radiation coating

[0069] 1. Take resin, wave-absorbing filler, surface treatment agent, graphene, surfactant and solvent by weight ratio in Table 5;

[0070] 2. First mix the graphene and the surface treatment agent evenly, then place the wave-absorbing filler in the vibrating sieve, the vibrating sieve vibrates at a frequency of 70 Hz, and drop the surface treatment agent mixed with graphene while vibrating; make the wave-absorbing filler Mix evenly with the surface treatment agent doped with graphene, then place in an oven and bake at 120 degrees for 1 hour to obtain a wave-absorbing filler with a coating;

[0071] 3. Mix the coated wave-absorbing filler, resin, surfactant and solvent obtained in step 2, and stir in a double planetary mixer for 50-60 minutes to obtain a uniformly mixed mixture;

[0072] 4. The mixed solution that step 3 is obtained is filtered, and vacuum defoaming is made into graphene type anti-radiation coating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com