Surface plating composite coating process for die

A composite coating and process technology, applied in the field of surface infiltration composite coating technology for molds, can solve the problems of high production cost and harsh process conditions, and achieve the effects of reducing friction coefficient, low process temperature and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

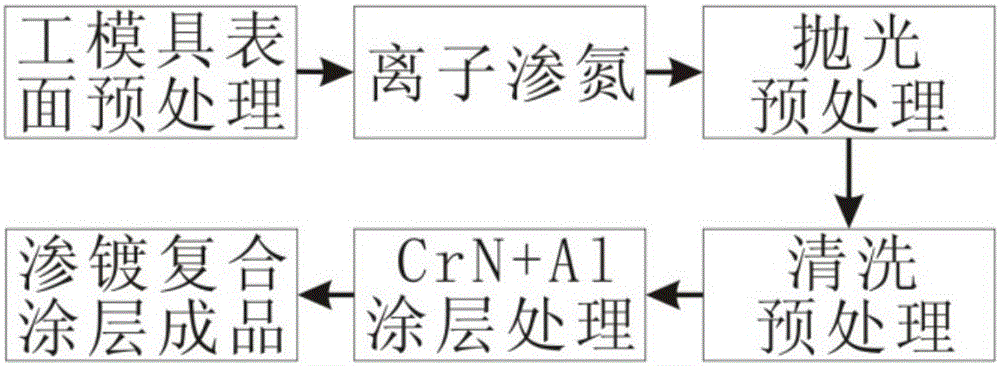

[0028] A kind of surface permeation plating composite coating technology for mold, its technological process is as attached figure 1 Shown, wherein, described ion nitriding comprises the following steps:

[0029] (1) Loading mold workpieces: When loading, pay attention to the sufficient distance between different workpieces, and use screws or splints to block the screw holes or gaps on the workpieces whose size is less than 6mm;

[0030] (2) Vacuuming: Select the nitriding program on the control panel, start the Vessel button, start vacuuming, and start heating when the vacuum reaches the critical value;

[0031] (3) Heating stage: vacuumize to below 10Pa to start heating, and conduct heating by pulse voltage ion discharge. Three thermocouples are evenly installed in the furnace to measure and adjust the temperature to keep the temperature in the furnace uniform, and heat to 430°C; specifically, The heating process includes three stages. The first stage is: heating from room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com