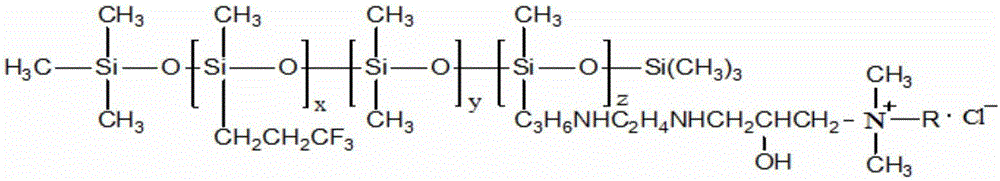

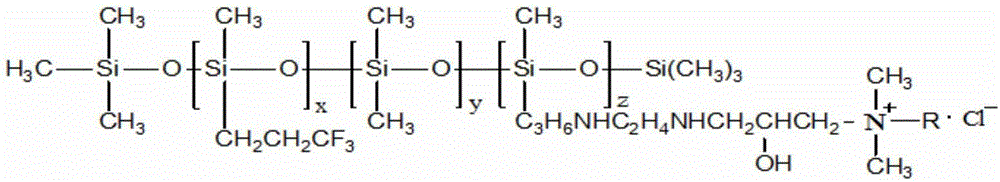

Cation-type quaternization organic fluorosilicon oil darkening finishing agent, and preparation method and application thereof

An organic fluorosilicone oil and cationic technology, which is applied in the field of darkening treatment of dark polyester fabrics, can solve problems such as further improvement of darkening effect, impact on textile quality, and occurrence of oil floating, and achieves environmental protection in the preparation process, convenient preparation, and easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a method for preparing a cationic quaternized organofluorosilicone oil darkening finishing agent includes the following steps:

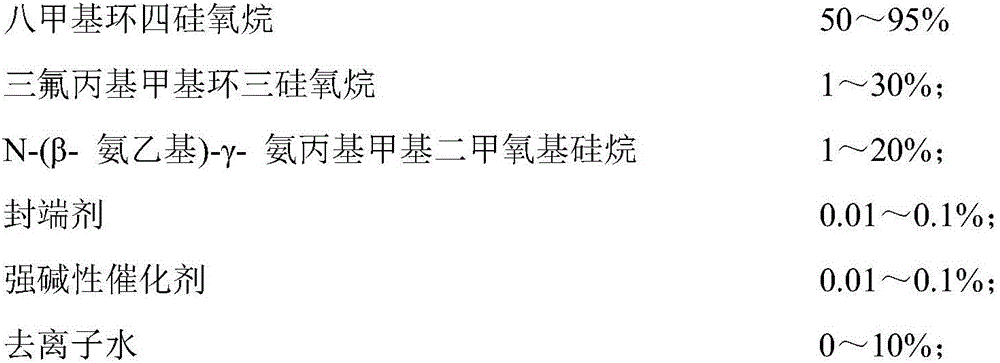

[0033] a. Synthesis of aminohydrocarbyl modified organic fluorosilicone oil: the raw materials used and their weights are as follows:

[0034]

[0035] First, 30g of octamethylcyclotetrasiloxane (D4) was added to a three-necked flask equipped with a stirrer and a reflux condenser, and the water bath was heated to 90°C, and 3g of N-(β-aminoethyl)- γ-aminopropylmethyldimethoxysilane (KH602) is mixed with 0.6g of deionized water to prepare an aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane; then Slowly drop the aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane into the three-necked flask, mix and stir with the octamethylcyclotetrasiloxane in the three-necked flask, and stir After uniformity, add 0.015g of KOH strong basic catalyst, react at 90°C for 1 hour, then raise the tempe...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

[0042] A method for preparing a cationic quaternized organofluorosilicone oil darkening finishing agent, comprising the following steps:

[0043] a. Synthesis of aminohydrocarbyl modified organic fluorosilicone oil: the raw materials used and their weights are as follows:

[0044]

[0045] First, 25g of octamethylcyclotetrasiloxane (D4) was added to a three-necked flask equipped with a stirrer and a reflux condenser, the water bath was heated to 90°C, and 3g of N-(β-aminoethyl)- γ-aminopropylmethyldimethoxysilane (KH602) is mixed with 0.6g of deionized water to prepare an aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane; then Slowly drop the aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane into the three-necked flask, mix and stir with the octamethylcyclotetrasiloxane in the three-necked flask, and stir After uniformity, add 0.015g of KOH stron...

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

[0052] In this embodiment, a method for preparing a cationic quaternized organofluorosilicone oil darkening finishing agent includes the following steps:

[0053] a. Synthesis of aminohydrocarbyl modified organic fluorosilicone oil: the raw materials used and their weights are as follows:

[0054]

[0055] First, 30g of octamethylcyclotetrasiloxane (D4) was added to a three-necked flask equipped with a stirrer and a reflux condenser, and the water bath was heated to 90°C, and 3g of N-(β-aminoethyl)- γ-aminopropylmethyldimethoxysilane (KH602) is mixed with 0.6g of deionized water to prepare an aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane; then Slowly drop the aqueous solution of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane into the three-necked flask, mix and stir with the octamethylcyclotetrasiloxane in the three-necked flask, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com