Preparation method for blended yarns of hemp cotton and antibacterial fibers

A technology of antibacterial fiber and blended yarn, which is applied in the textile field, can solve the problems of unstable antibacterial effect and short antibacterial time, and achieve the effect of obvious antibacterial effect, fast sterilization rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

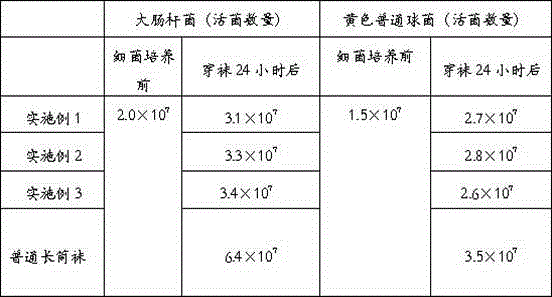

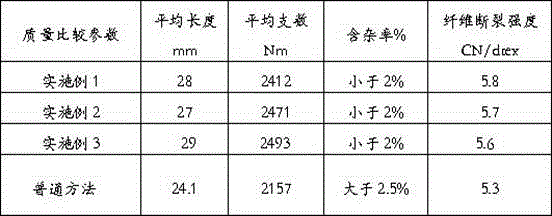

Embodiment 1

[0044] A kind of hemp cotton of the present invention adds the preparation method of the blended yarn of antibacterial fiber, comprises the steps:

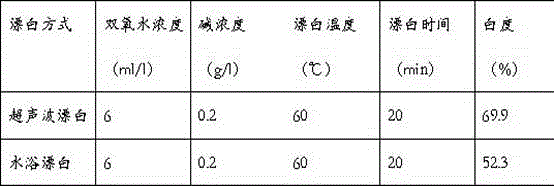

[0045] (1) Proportionally blending the prepared hemp-cotton blended fiber and antibacterial fiber, plying and twisting to obtain a roving, after mixing and matching, spinning into a raw roving and then scouring and bleaching the roving;

[0046] The preparation steps of hemp-cotton blended fiber are:

[0047] Soak the hemp fiber and cotton fiber in acetone, carry out ultrasonic shock treatment at the same time, dehydrate and dry after washing, and obtain the hemp-cotton blended fiber; mix the hemp-cotton blended fiber in proportion and twist it into a blended yarn; wherein, the The mass ratio of hemp fiber and cotton fiber mentioned above is 2:1.

[0048] The antibacterial fiber includes the following components counted in parts by weight:

[0049] 10 parts of hydroxymethyl cellulose

[0050] 20 parts methyl cellulose

[0051]...

Embodiment 2

[0068] The difference between embodiment 2 and embodiment 1 is:

[0069] A kind of hemp cotton of the present invention adds the preparation method of the blended yarn of antibacterial fiber, comprises the steps:

[0070] In step (1), the mass ratio of the hemp fiber to the cotton fiber is 4:1.

[0071] The antibacterial fiber includes the following components counted in parts by weight:

[0072] 12 parts of hydroxymethylcellulose,

[0073] 25 parts of methylcellulose,

[0074] Nano zinc oxide polyurethane microcapsules 18 parts,

[0075] 12 parts of silver nitrate composite particles,

[0076] Polyterephthalic acid 5 parts,

[0077] 15 parts of nano-silver oxide composite particles,

[0078] silk yarn 15 parts,

[0079] sisal yarn 13 parts.

[0080] nano-SiO 2 The dispersion was added dropwise to the AgNO 3 solution, adjust the pH value of the solution to 8, react for 4.5 hours, centrifuge, wash with deionized water and dry, that is, nano-silver loaded SiO 2 partic...

Embodiment 3

[0089] The difference between embodiment 3 and embodiment 1 is: a kind of hemp cotton of the present invention adds the preparation method of the blended yarn of antibacterial fiber, comprises the steps:

[0090] In step (1), the mass ratio of the hemp fiber to the cotton fiber is 6:1.

[0091] The antibacterial fiber includes the following components counted in parts by weight:

[0092] 15 parts of hydroxymethylcellulose,

[0093] 30 parts of methylcellulose,

[0094] Nano zinc oxide polyurethane microcapsules 30 parts,

[0095] 20 parts of silver nitrate composite particles,

[0096] Polyterephthalic acid 7 parts,

[0097] 20 parts of nano-silver oxide composite particles,

[0098] Silk yarn 20 parts,

[0099] sisal yarn 15 parts.

[0100] nano-SiO 2 The dispersion was added dropwise to the AgNO 3 solution, adjust the pH value of the solution to 9, react for 5 hours, centrifuge, wash with deionized water and dry to prepare nano-silver loaded SiO 2 particles.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com