Double-cylinder steady-flow conveying pump and towed pump and pump truck adopting the double-cylinder steady-flow conveying pump

A delivery pump and steady flow technology, which is applied to the components, pumps, piston pumps, etc. of the pumping device used for elastic fluids, and can solve the impact of pumping equipment, delivery pipeline valves, affecting reliability and service life, delivery Pipeline blockage and other problems, to achieve stable delivery flow and pressure, not easy to fatigue damage, eliminate the effect of pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

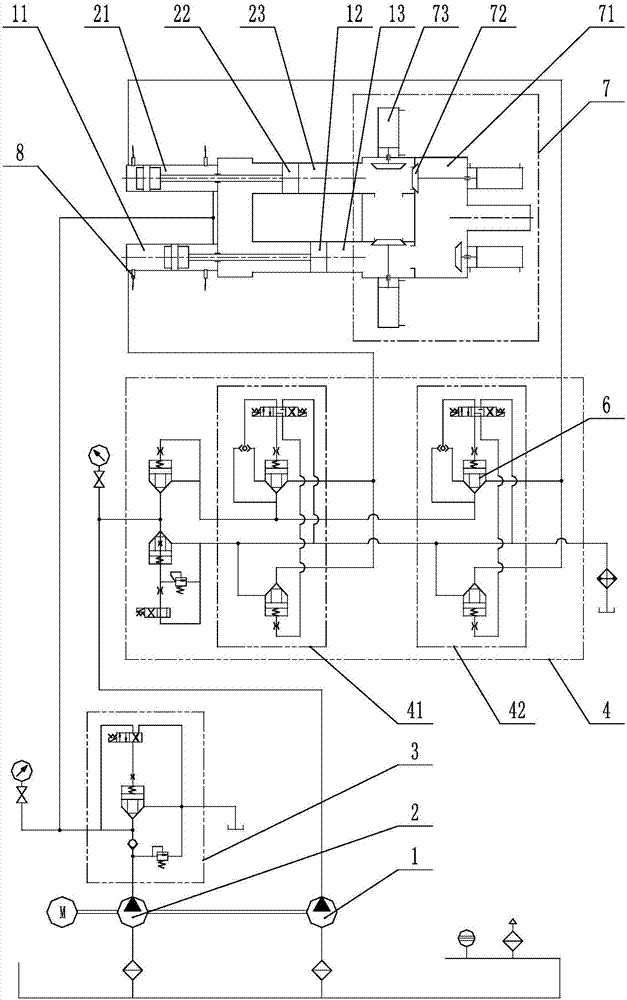

[0059] see figure 1 , which shows a schematic diagram of a dual-cylinder steady-flow delivery pump in a preferred embodiment of the present invention. The double-cylinder steady-flow conveying pump includes: pumping hydraulic pump 1, fast-reverse hydraulic pump 2, fast-reverse hydraulic valve group 3, pumping hydraulic valve group 4, cartridge valve 6, distribution valve group 7, pressure-resistant travel switch 8 , Pumping hydraulic cylinder A11, Pumping piston A12, Pumping cylinder A13, Pumping hydraulic cylinder B21, Pumping piston B22, Pumping cylinder B23, Pumping hydraulic valve group A41, Pumping hydraulic valve group B42, Distribution valve box 71, seat valve valve head 72, valve driving device 73.

[0060] In the figure, the part within the double-dot dash line indicated by serial number 3 is the fast-reverse hydraulic valve group, the part within the double-dot dash line indicated by serial number 4 is the pumping hydraulic valve group, and the part within the doubl...

Embodiment 2

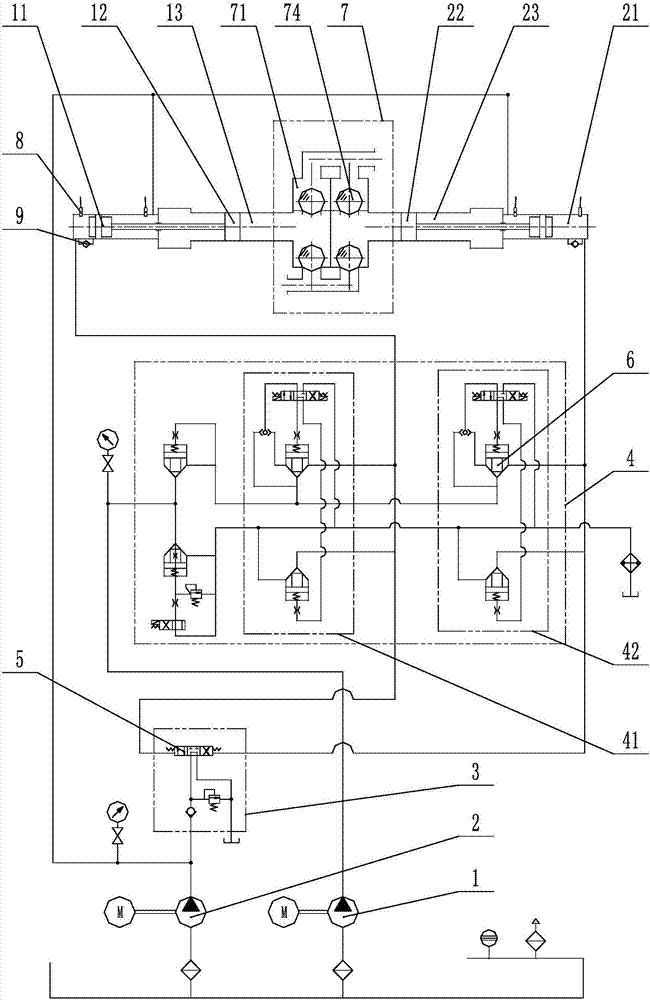

[0105] see figure 2 , which shows a schematic diagram of a double-cylinder steady-flow delivery pump according to another preferred embodiment of the present invention. The double-cylinder steady-flow conveying pump includes: pumping hydraulic pump 1, fast-reverse hydraulic pump 2, fast-reverse hydraulic valve group 3, pumping hydraulic valve group 4, hydraulic reversing valve 5, cartridge valve 6, distribution valve group 7 , pressure limit switch 8, one-way valve 9, pumping hydraulic cylinder A11, pumping piston A12, pumping cylinder A13, pumping hydraulic cylinder B21, pumping piston B22, pumping cylinder B23, pumping hydraulic valve group A41 , Pumping hydraulic valve group B42, distribution valve box 71, valve ball 74.

[0106] In the figure, the part within the double-dot dash line indicated by serial number 3 is the fast-reverse hydraulic valve group, the part within the double-dot dash line indicated by serial number 4 is the pumping hydraulic valve group, and the pa...

Embodiment 3

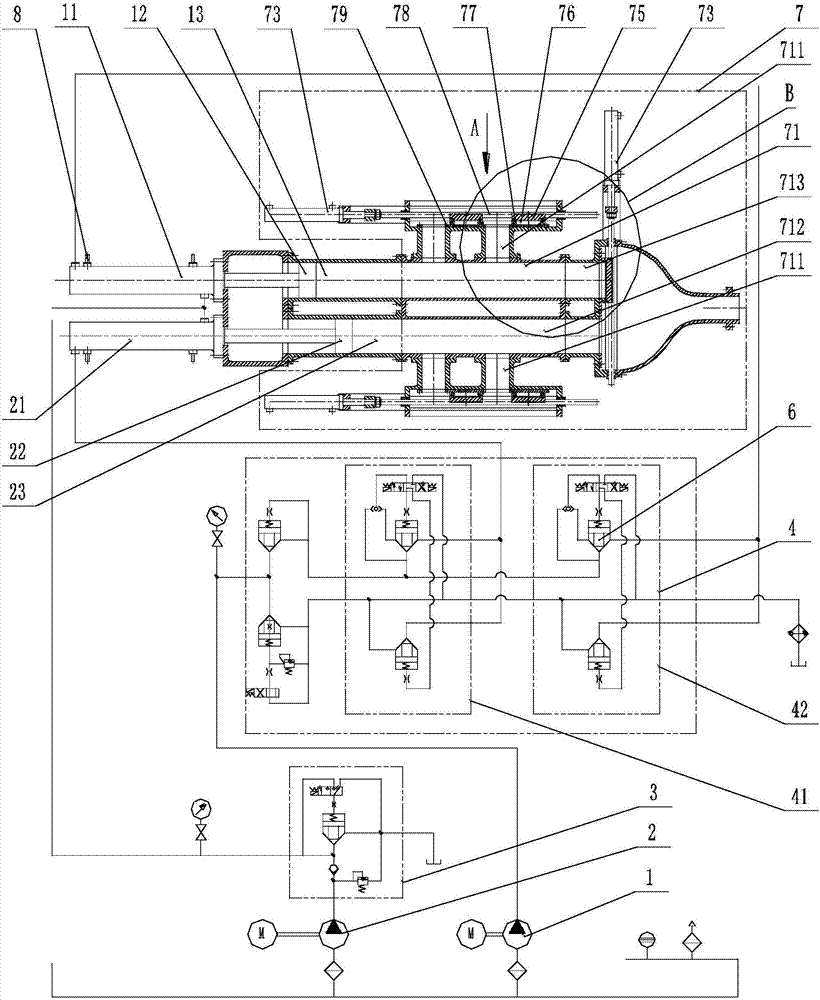

[0140] see image 3 , Figure 4 and Figure 5 , which shows a schematic diagram of a double-cylinder steady-flow delivery pump according to another preferred embodiment of the present invention. The double-cylinder steady-flow conveying pump includes: pumping hydraulic pump 1, fast-reverse hydraulic pump 2, fast-reverse hydraulic valve group 3, pumping hydraulic valve group 4, cartridge valve 6, distribution valve group 7, pressure-resistant travel switch 8 , Pumping hydraulic cylinder A11, Pumping piston A12, Pumping cylinder A13, Pumping hydraulic cylinder B21, Pumping piston B22, Pumping cylinder B23, Pumping hydraulic valve group A41, Pumping hydraulic valve group B42, Distribution valve box 71. Valve driving device 73, sliding body 75, sliding seal 76, elastic seal 77, guide rod 78, friction plate 79. The distribution valve box 71 further includes a distribution valve body 1 711 , a distribution valve body 2 712 and a distribution valve body 3 713 , and the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com