Photoelectric response based method for identifying and detecting vapor of explosive

A photoelectric response and detection method technology, applied in the field of explosives detection, can solve the problems of complex structure of sensing system, complex construction process, multiple synthesis or modification steps, etc., to simplify the sensor array structure, compensate for the complex structure, and improve the detection limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

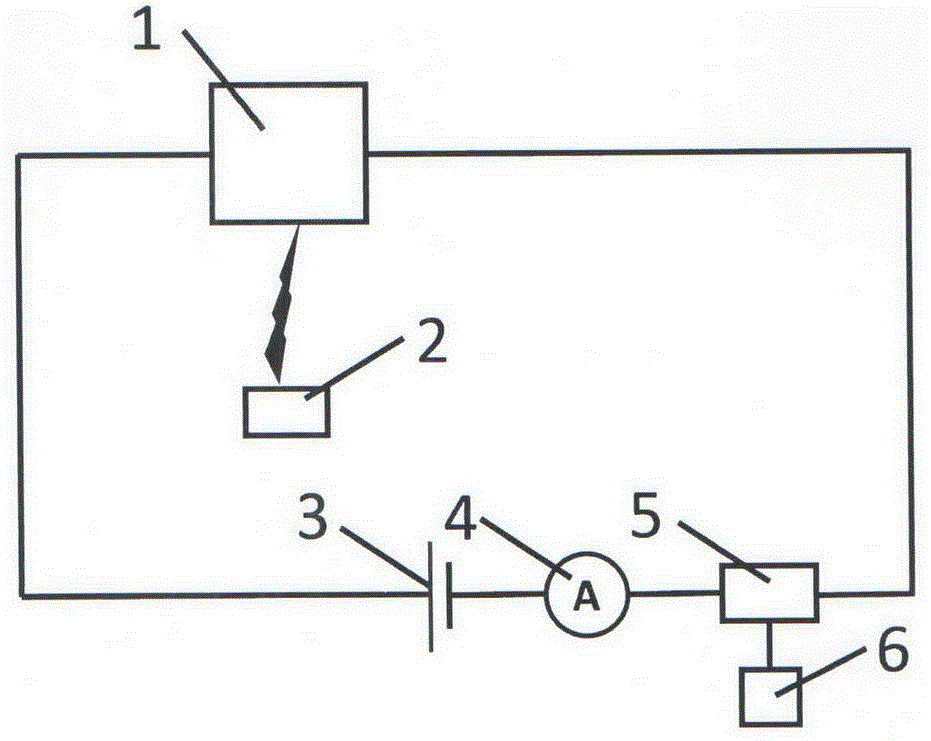

[0027]A method for identifying and detecting explosive vapor based on photoelectric response according to the present invention, the devices involved in the method are composed of sensors, light sources, power supplies, ammeters, signal processors and alarms, sensor 1, light source 2, power supply 3 , the ammeter 4 is connected in series with the signal processor 5, the signal processor 5 is connected with the alarm 6, and the light source 2 that can be periodically switched and changed in light intensity is used to irradiate a single sensor 1 with a fast photoelectric response, and on the sensor 1 The sensitive materials are silicon-zinc oxide p-n junction, silicon nanowire / graphene Schottky junction, titanium dioxide / graphene Schottky junction, silicon-zinc oxide core-shell nanowire array / graphene Schottky junction, silicon nanowire Wire / metal Schottky junction, silicon nanowire array, titanium dioxide modified silicon nanowire array / graphene Schottky junction or gold nanopar...

Embodiment 2

[0034] The device involved in the method is the same as in Example 1, and the specific operations are carried out in the following steps:

[0035] a. A light source 2 is installed above the silicon-zinc oxide sensitive material of the sensor 1, and the light source 2 with a wavelength of 468nm irradiates the sensitive material;

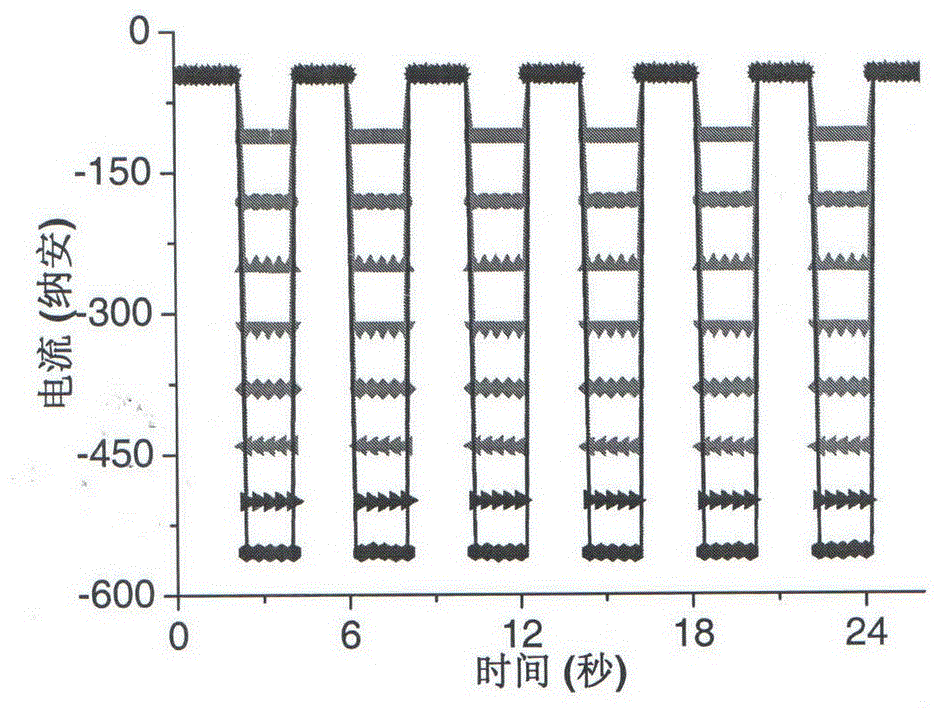

[0036] b. Put the sensor 1 in the air, and at room temperature, turn on and off the light source 2 periodically at an interval of 1 ms and change the light intensity. The light intensity is 1 W / m 2 , 2W / m 2 , 3W / m 2 , 4W / m 2 , 5W / m 2 、6W / m 2 , measure the photocurrent of the silicon-zinc oxide sensitive material under different light intensities, and obtain the baseline current value;

[0037] c. Place the sensor 1 at room temperature respectively in trinitrotoluene (TNT), dinitrotoluene (DNT), picric acid (PA), RDX, pentaerythritol tetranitrate (PETN) and cyclotetraethylene In the saturated vapor of methyltetranitramine (HMX), by periodically t...

Embodiment 3

[0041] The device involved in the method is the same as in Example 1, and the specific operations are carried out in the following steps:

[0042] a. A laser light source 2 is installed above the titanium dioxide-modified silicon nanowire array / graphene Schottky junction sensitive material of the sensor 1, and the light source 2 has a wavelength of 532nm to irradiate the sensitive material;

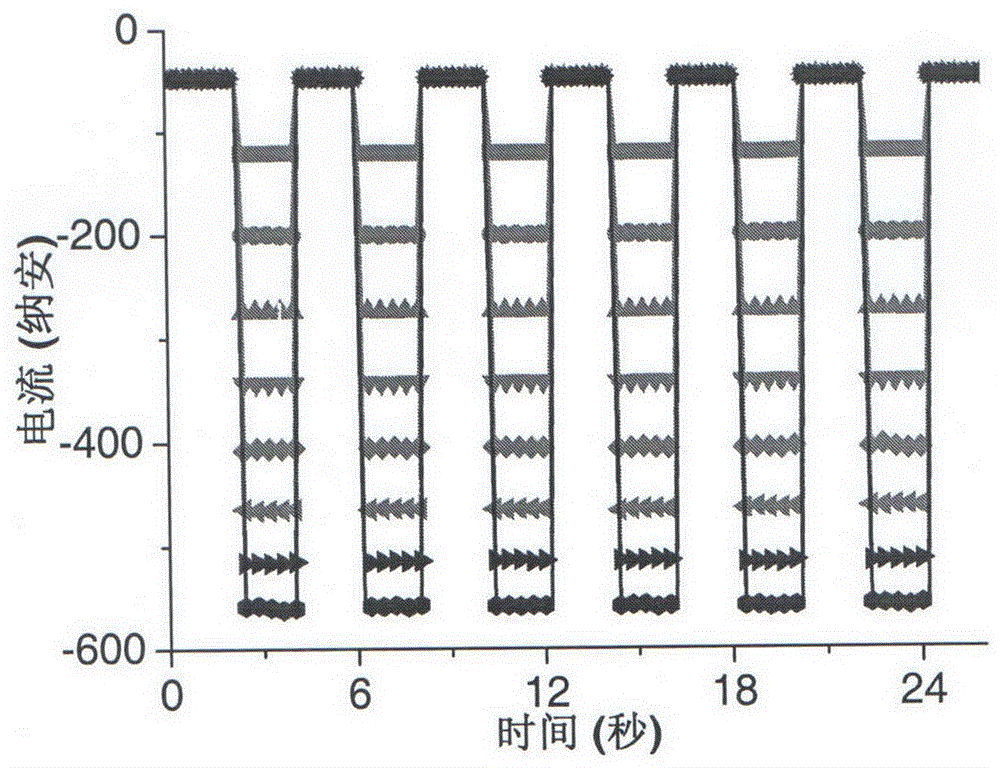

[0043] b. Put the sensor 1 in the air, at room temperature, turn on and off the light source 2 periodically at an interval of 100ms and change the light intensity, the light intensity is 1W / m 2 , 2W / m 2 , 3W / m 2 , 4W / m 2 , 5W / m 2 、6W / m 2 , 7W / m 2 , 8W / m 2 , 9W / m 2 , 10W / m 2 , measure the photocurrent of titanium dioxide-modified silicon nanowire array / graphene Schottky junction sensitive material under different light intensities, and obtain the baseline current value;

[0044] c. Place the sensor 1 in the saturated vapor of black powder (BP), dinitrotoluene (DNT), picric acid (P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com