Ionic liquid functional composite membrane modified electrode and preparation method and application thereof to detection of chlorophenol

A technology of ionic liquids and modified electrodes, which is used in measurement devices, electrochemical variables of materials, material analysis by electromagnetic means, etc., to achieve the effects of enhancing electrical conductivity, simple method operation, and improving specific surface area and electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (a) Preparation of AuNPs dispersion

[0034] Take 100mL of HAuCl with a mass concentration of 0.01% 4 Aqueous solution, heated to boiling, slowly added 1.5mL sodium citrate solution with a mass fraction of 1% under continuous stirring, continued stirring and heating and boiling for 15min, the solution turned purple and cooled to room temperature, and restored to the original volume with deionized water to obtain AuNPs Dispersions;

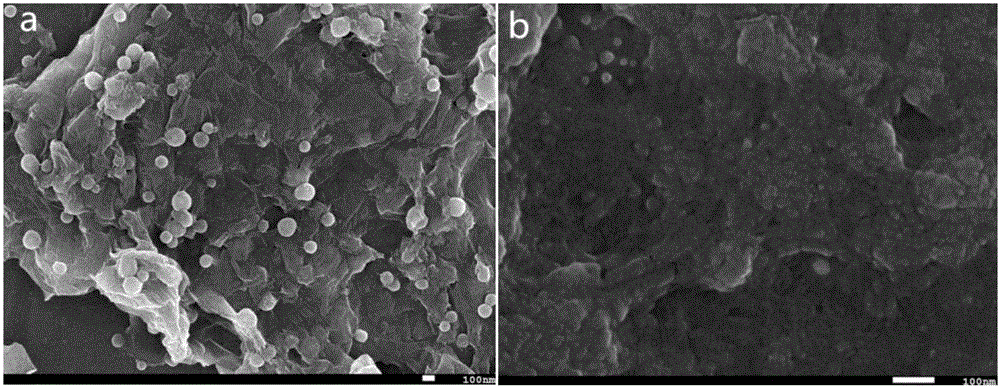

[0035] (b) Preparation of GO-AuNPs nanocomposites

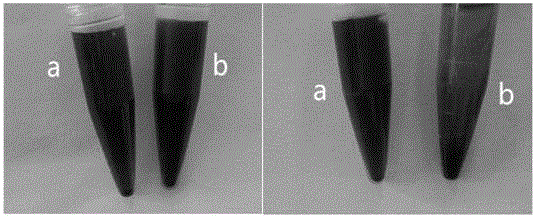

[0036] GO was prepared by the hummer method, and a certain amount of GO was dispersed in water to make the concentration 5mg / mL, ultrasonically dispersed for 2 hours, and centrifuged at 3000rpm for 10min to remove undispersed GO to obtain a stripped GO dispersion; take 20mL of the GO Dispersion solution, slowly add 10mL of AuNPs dispersion solution dropwise under constant stirring, mix well and then stir for 12 hours under airtight conditions at room temperature, centrifuge at 5000rmp for...

Embodiment 2

[0042] (a) Preparation of AuNPs

[0043] Prepared according to the method and conditions in step (a) in Example 1;

[0044] (b) Preparation of GO-AuNPs nanocomposites

[0045] Prepared according to the method and conditions in step (b) in Example 1;

[0046] (c) Preparation of IL-GR-AuNPs composites

[0047] Weigh 20 mg of the GO-AuNPs composite obtained in step (b) and disperse it in 20 mL of deionized water, slowly add 10 mg IL and 10 mg KOH to it, and then sonicate for 30 min; heat, stir and reflux the sonicated dispersion at 80 °C for 24 h , the obtained product was centrifuged at 8000rmp for 5min, washed with water and absolute ethanol three times in turn, and the obtained black solid substance was the IL-GR-AuNPs complex;

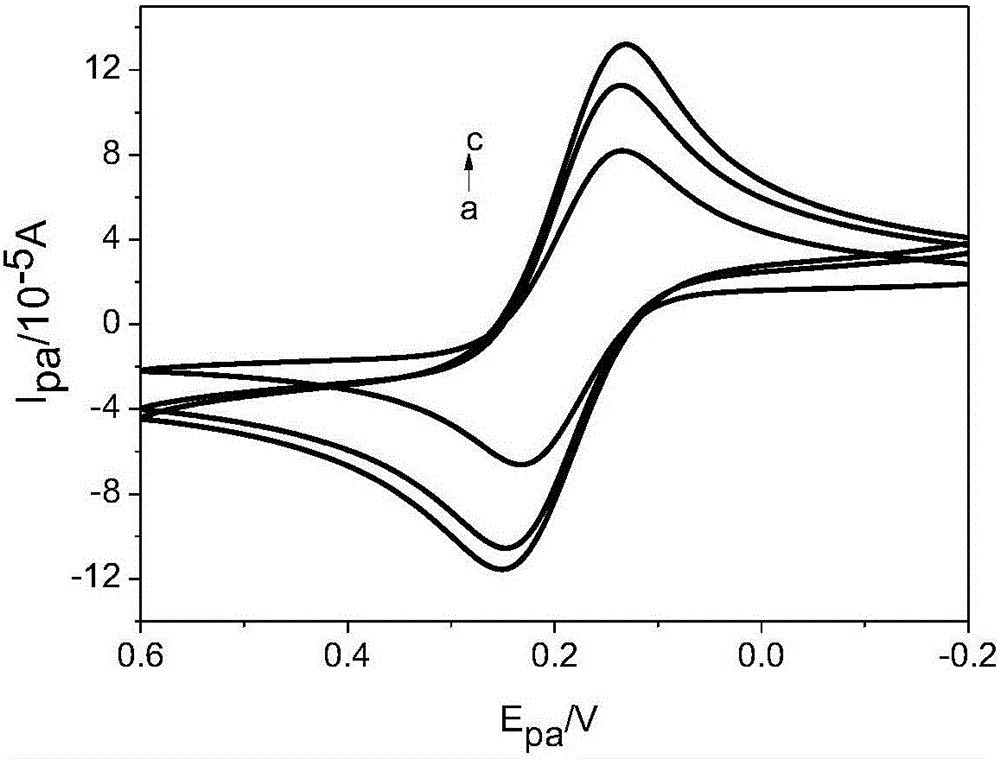

[0048] (d) Preparation of IL-GR-AuNPs composite modified glassy carbon electrode

[0049] Prepare according to the method and conditions in step (d) in Example 1.

Embodiment 3

[0051] (a) Preparation of AuNPs

[0052] Prepared according to the method and conditions in step (a) in Example 1;

[0053] (b) Preparation of GO-AuNPs nanocomposites

[0054] Prepared according to the method and conditions in step (b) in Example 1;

[0055] (c) Preparation of IL-GR-AuNPs composites

[0056] Weigh 30 mg of the GO-AuNPs composite obtained in step (b) and disperse it in 20 mL of deionized water, slowly add 10 mg IL and 10 mg KOH to it, and then sonicate for 30 min; heat, stir and reflux the sonicated dispersion at 80 °C for 24 h , the obtained product was centrifuged at 8000rmp for 5min, washed with water and absolute ethanol three times in turn, and the obtained black solid substance was the IL-GR-AuNPs complex;

[0057] (d) Preparation of IL-GR-AuNPs composite modified glassy carbon electrode

[0058] Prepare the IL-GR-AuNPs composite material obtained in step (c) with deionized water into a slurry with a concentration of 1 mg / mL, take 10 μL of the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com