Multilayer ceramic electronic device

A technology for electronic components and ceramics, which is applied in the field of laminated ceramic electronic components, can solve the problem of not establishing cracks, etc., and achieve the effects of less reduction in electrostatic capacitance and suppression of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

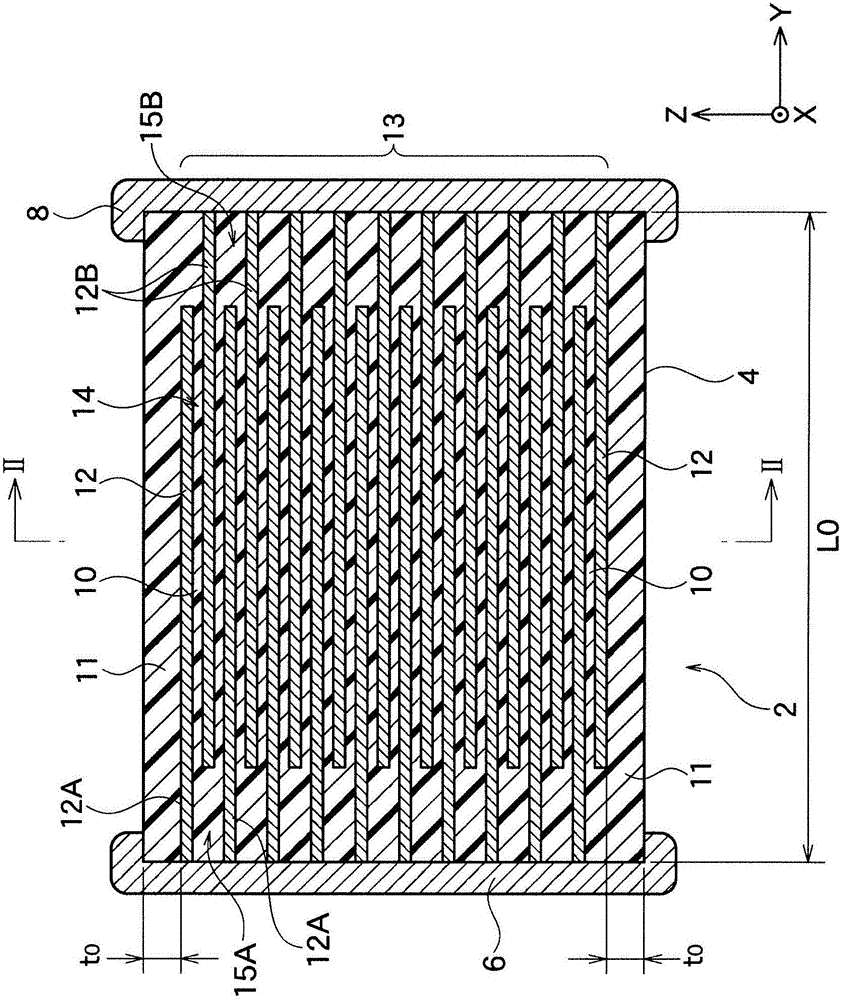

Embodiment 1

[0086] First, as the raw material powder of the main raw material, {(Ba 1-x-y Ca x Sr y )O} u (Ti 1-z Zr z ) v o 3 powder (x=0.05, y=0, z=0.05, u / v=1.004), then prepare MgCO 3 , MnCO 3 , Y 2 o 3 , SiO 2 as a side ingredient. In addition, the subcomponents are preliminarily crushed and processed to a particle diameter of about 40 nm smaller than that of the barium titanate raw material.

[0087] Next, 0.5 mol of MgCO was weighed for each raw material powder prepared above with respect to 100 mol of the main raw material. 3 powder, 0.3 mol MnCO 3 powder, 0.2 mole of Y 2 o 3 powder and weigh 2 moles of SiO 2 powder. These respective powders were wet-mixed with a ball mill and dried for 20 hours to obtain a dielectric raw material for the capacitor part. BaCO added at this time 3 , MnCO 3 After firing, they are contained in the dielectric ceramic composition as BaO and MnO, respectively.

[0088] Next, the obtained dielectric raw material: 100 parts by weight,...

Embodiment 2

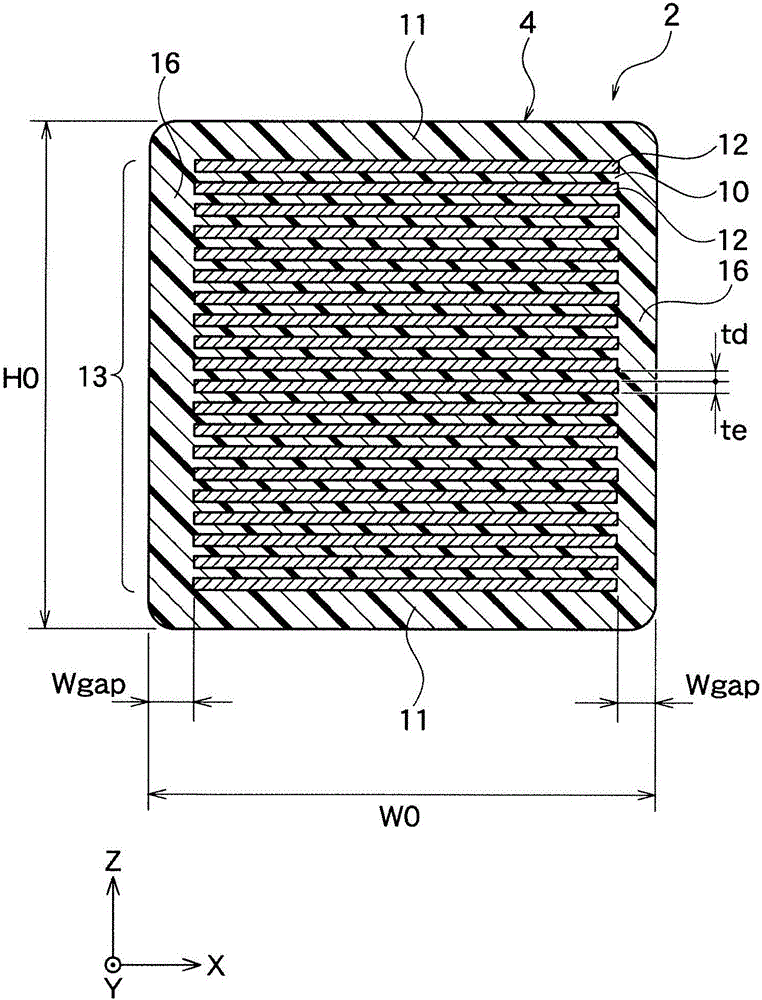

[0110] As shown in Table 2, except that the thickness td of the dielectric layer 10 after firing and the thickness te of the internal electrode layer 12 after firing were set to 0.3 μm, samples of laminated ceramic capacitors were produced in the same manner as in Example 1, and measured Their electrostatic capacitance and crack generation rate. The results are shown in Table 2.

[0111] [Table 2]

[0112]

[0113] Evaluation 1

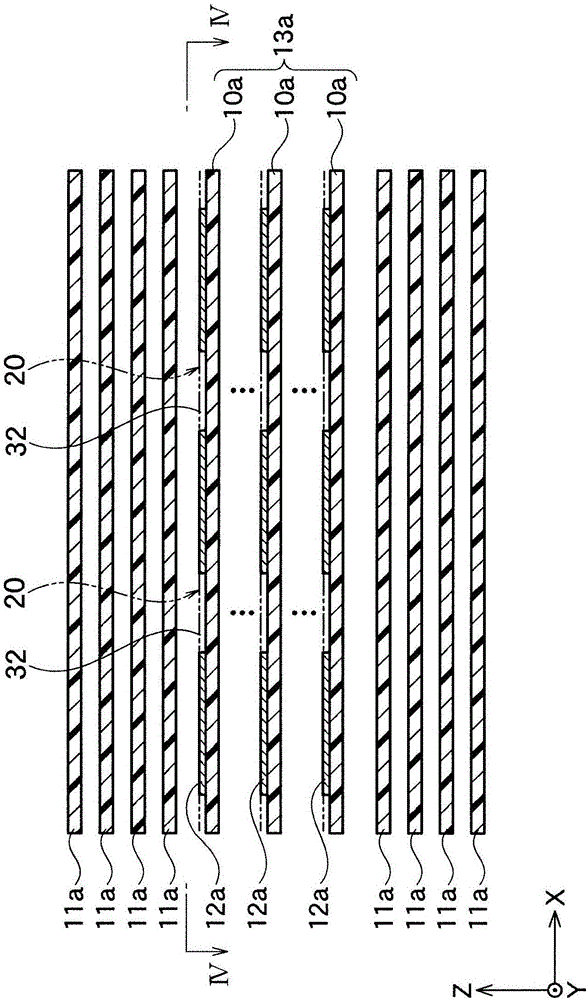

[0114] From the results shown in Table 1 and Table 2, it can be confirmed that the thickness td of the dielectric layer is 0.4 μm or less, the width dimension W0 is 0.59 mm or less, the gap dimension Wgap is 0.010 to 0.025 mm, and the ratio (Wgap / W0 dimension) is 0.025 or more, a multilayer ceramic capacitor with a low crack occurrence rate and a small decrease in capacitance.

Embodiment 3

[0116] As shown in Table 3, except that the thickness te of the internal electrode layer 12 after firing was changed, samples of multilayer ceramic capacitors were produced in the same manner as in Example 1, and their capacitances and crack occurrence rates were measured. The results are shown in Table 3.

[0117] [table 3]

[0118]

[0119] Evaluation 2

[0120] From the results shown in Table 3, it was confirmed that when te / td is less than 1.25, and particularly preferably te / td is 0.95 to 1.05, a multilayer ceramic capacitor with a low rate of occurrence of cracks and a small decrease in capacitance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gap size | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com