A method for regulating the growth of spherical rubrene crystal thin films by co-solvent of polymer-induced layer

A rubrene and polymer technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of poor film formation and difficult crystallization, and achieve good film formation, low cost and high load. The effect of carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

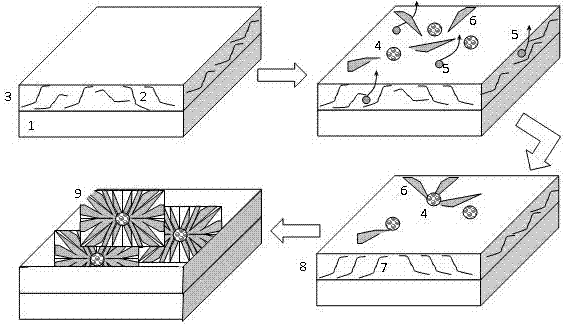

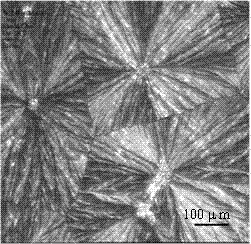

[0009] Such as figure 1 As shown, the Si / SiO 2 Substrate Substrate (1) Soak in piranha solution heated at 90°C in a water bath for 25 minutes for substrate treatment. Rinse once, blow dry with nitrogen, and dry in an oven. Treated Si / SiO 2 The substrate substrate (1) is placed on the glue homogenizer, and the PS solution (2) of chloroform solvent is uniformly dripped on the substrate, and the forward rotation is 400rpm, and the rear rotation is 1250rpm. Coat the PS film to form a layer of PS film (3) with a uniform and directional arrangement on the substrate modification layer; then apply the rubrene solution (4) in chloroform solvent evenly on the PS film, and in the chloroform solvent (5) During the volatilization process, the control-induced layer PS film (3) arranged more orderly (2), and rubrene crystals also began to gather and grow orderly (6); then, the film was cured and dried for 10 min in an 80°C drying oven. Using the properties of the co-solvent, the microsco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com