Silver mine tailings ultra-fine activated fine powder and preparation technology thereof

A kind of ultra-fine powder, technology, applied in the direction of grain processing, etc., can solve the problems of incomplete preparation technology, low production efficiency, small application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Structural arrangement for specific implementation.

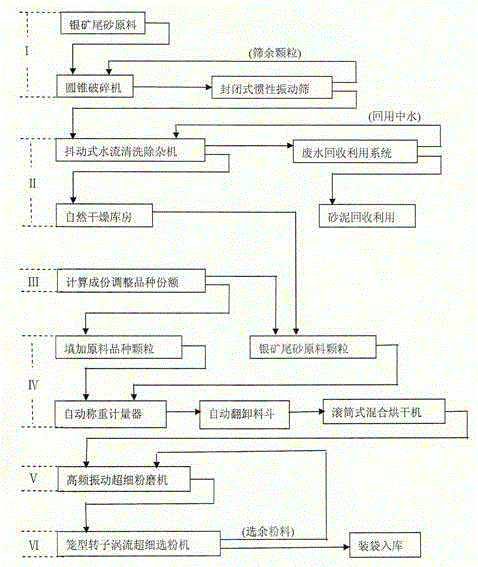

[0045] as attached figure 1 As shown, the silver ore tailings ultra-fine activated micro-powder and its preparation technology researched and designed in this patent include operational technology units such as crushing and screening, cleaning and impurity removal, component adjustment, mixing and drying, ultra-fine grinding, and eddy current powder selection. And its configured technical equipment and operating procedures.

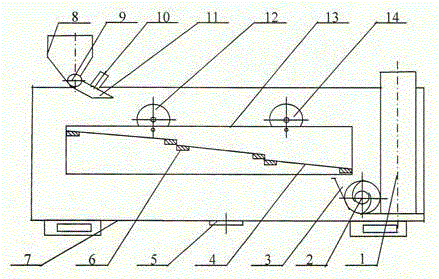

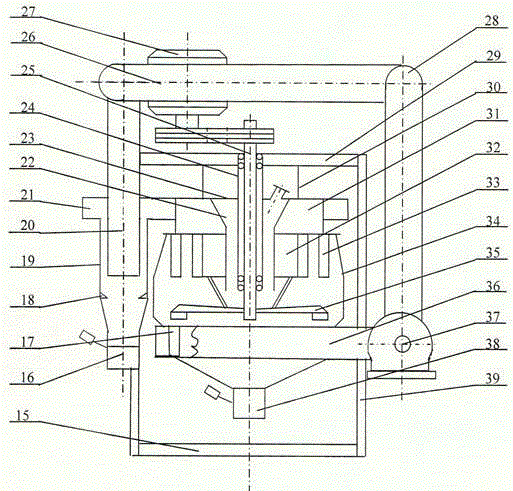

[0046] as attached figure 1 As shown, the crushing and screening operation technical unit (I) is completed by the configured cone crusher and closed inertia vibrating screen. The cone crusher consists of a machine base, a shell, a spring screw, a fixed cone, a moving cone, a main drive shaft, a distribution tray, an eccentric shaft sleeve, and a power transmission device; Structural layout, the cone-shaped crushing chamber is composed of the inner surface of the fixed cone and the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com