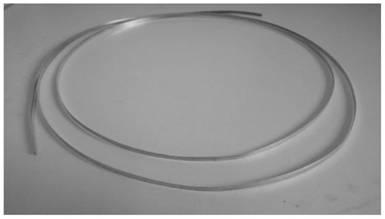

Method for preparing bismuth ferrite-based strip material by coating ceramic powder with silver tube

A ceramic powder and bismuth ferrite-based technology, which is applied in the field of preparing bismuth ferrite-based strips coated with silver tube ceramic powder, achieves the effects of high efficiency, improved uniformity, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

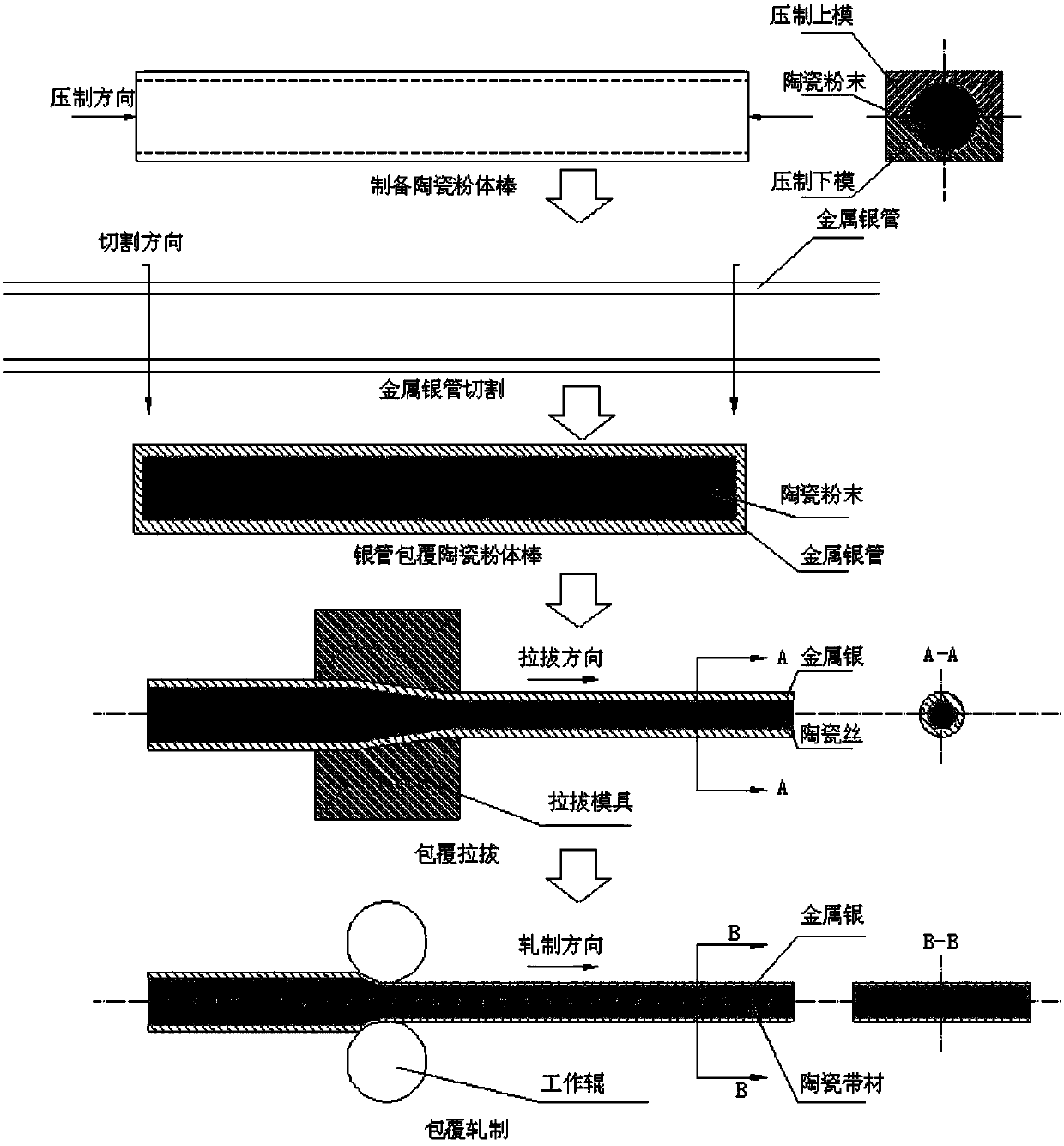

[0031] The method for preparing bismuth ferrite-based strip material by coating ceramic powder with silver tube includes the following steps:

[0032] Step 1. Prepare ceramic powder rod:

[0033] (1) Using the sol-gel self-combustion method, prepare 9g of bismuth ferrite-based ceramic powder with a particle size of ≤500nm.

[0034] (2) Fill the bismuth ferrite-based ceramic powder in the lower mold, and then close the upper and lower molds and place them on the hydraulic press for compression; it is compressed into a ceramic powder rod with a diameter of 6mm and a length of 115mm. 4MPa, the pressing time is 10s;

[0035] Step 2. Silver tube coated ceramic powder rod:

[0036] (1) Cut to obtain a silver tube; among them, the wall thickness of the silver tube is 1mm, the outer diameter of the silver tube is 8mm, and the length of the silver tube is 120mm;

[0037] (2) Put the ceramic powder rod into the silver tube, and seal both ends of the silver tube by argon arc welding;

[0038] Step ...

Embodiment 2

[0044] The method for preparing bismuth ferrite-based strip material by coating ceramic powder with silver tube includes the following steps:

[0045] Step 1. Prepare ceramic powder rod:

[0046] (1) Using traditional sol-gel method to prepare 0.97BiFeO3-0.03BaTiO 3 18g of bismuth ferrite-based binary solid solution powder, particle size ≤500nm;

[0047] (2) Fill the binary solid solution powder in the lower mold, then close the upper and lower molds, and place them on the hydraulic press for pressing; press into a ceramic powder rod with a diameter of 8mm and a length of 110mm, where the pressure during pressing 8MPa, the pressing time is 15s;

[0048] Step 2. Silver tube coated ceramic powder rod:

[0049] (1) Cut to obtain a silver tube; wherein the wall thickness of the silver tube is 1mm, the outer diameter of the silver tube is 10mm, and the length of the silver tube is 120mm;

[0050] (2) Put the ceramic powder rod into the silver tube, and seal both ends of the silver tube by ar...

Embodiment 3

[0057] The method for preparing bismuth ferrite-based strip material by coating ceramic powder with silver tube includes the following steps:

[0058] Step 1. Prepare ceramic powder rod:

[0059] (1) Using the sol-gel self-combustion method, prepare 7g of bismuth ferrite-based ceramic powder with a particle size of ≤500nm;

[0060] (2) Fill the bismuth ferrite-based ceramic powder in the lower mold, then close the upper and lower molds, and place them on the hydraulic press for pressing; press into a ceramic powder rod with a diameter of 4mm and a length of 110mm. The pressure is 2MPa, and the pressing time is 10s;

[0061] Step 2. Silver tube coated ceramic powder rod:

[0062] (1) Cut to obtain a silver tube; wherein the wall thickness of the silver tube is 1mm, the outer diameter of the silver tube is 6mm, and the length of the silver tube is 120mm;

[0063] (2) Put the ceramic powder rod into the silver tube, and seal both ends of the silver tube by argon arc welding;

[0064] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com