UV curable offset printing scale ink for gold and silver cardboards

A technology of offset printing and photoinitiator, which is applied in the field of ink, can solve the problems of environmental pollution, unfavorable health of operators, unfavorable environmental protection, etc., and achieve the effect of improving comprehensive performance, improving slipperiness and scratch resistance, and reducing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

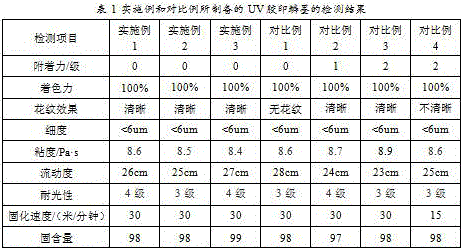

Examples

Embodiment 1

[0054] S1. 37 kg of aldehyde and ketone modified acrylate UV resin, 18 kg of polyester acrylate UV resin, 7 kg of trimethylolpropane triacrylate, 2.5 kg of 1-hydroxycyclohexyl phenyl ketone, 3.5 kg of 4- Isopropylthioxanthone, 7.5 kg of active amine, 21 kg of polyethylene wax, 0.6 kg of silicone leveling agent, and 0.4 kg of silicone defoamer were added while stirring and mixing evenly. The stirring speed was 800 rpm, stirring 10 minutes;

[0055] S2. Increase the rotating speed to 1600 rpm, add 2.5 kg of organic bentonite, stir for another 20 minutes, and filter and pack with a 150-mesh filter.

Embodiment 2

[0057] S1. 35 kg of aldehyde and ketone modified acrylate UV resin, 20 kg of polyester acrylate UV resin, 9 kg of trimethylolpropane triacrylate, 2 kg of 1-hydroxycyclohexyl phenyl ketone, 3 kg of 4- Isopropyl thioxanthone, 7 kg of active amine, 20 kg of polyethylene wax, 0.5 kg of silicone leveling agent, 0.5 kg of silicone defoamer and stir to mix evenly while adding, the stirring speed is 800 rpm, stirring 15 minutes;

[0058] S2. Increase the rotation speed to 1800 rpm, add 3 kg of organic bentonite, stir for another 10 minutes, and filter and pack with a 150-mesh filter.

Embodiment 3

[0060] S1. 33 kilograms of aldehyde and ketone modified acrylate UV resin, 22 kilograms of polyester acrylate UV resin, 12 kilograms of trimethylolpropane triacrylate, 1.5 kilograms of 1-hydroxycyclohexyl phenyl ketone, 2.5 kilograms of 4- Isopropyl thioxanthone, 6.5 kilograms of amine photoinitiators, 18 kilograms of polyethylene wax, 0.4 kilograms of organic silicon leveling agent, 0.6 kilograms of organic silicon defoaming agent are stirred and mixed evenly while adding, and the stirring speed is 1000 rpm minutes, stirring for 5 minutes;

[0061]S2. Increase the rotating speed to 1600 rpm, add 3.5 kg of organic bentonite, stir for another 30 minutes, and filter and pack with a 150-mesh filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com