Bacillus subtilis and application thereof to kitchen wastes

A technology of Bacillus subtilis and kitchen waste, applied in the field of microorganisms, can solve the problems of poor effect and low efficiency, and achieve the effect of good treatment effect, good development prospects, efficient, fast and stable treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Isolation and screening of Bacillus subtilis (Bacillus subtilis) CY-4

[0033] The separation process of Bacillus subtilis (Bacillus subtilis) CY-4 of the present invention: take Zhenjiang Jurong planting grape rhizosphere soil 10g, add 90mL sterile water, obtain 10 -1 Dilution, in a shaker at 30°C at 130r / min, cultured for 2-3h, continued to add sterile water to dilute to obtain 10 -5 , 10 -6 , 10 -7 , 10 -8 200uL of the above dilutions were spread on LB plates, cultured at 30°C for 48 hours, and a single colony was picked and inoculated on the slant of LB solid medium for preservation.

[0034] The physiological activity characteristics of Bacillus subtilis CY-4 are as follows:

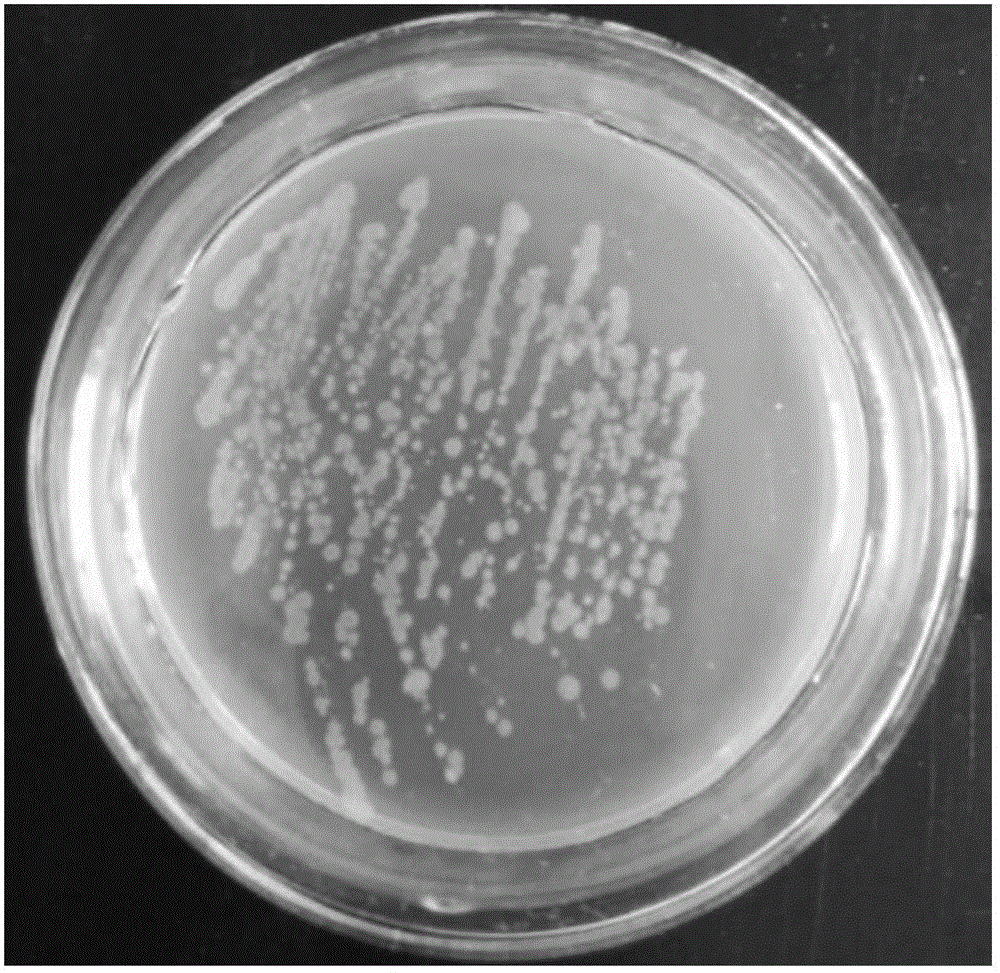

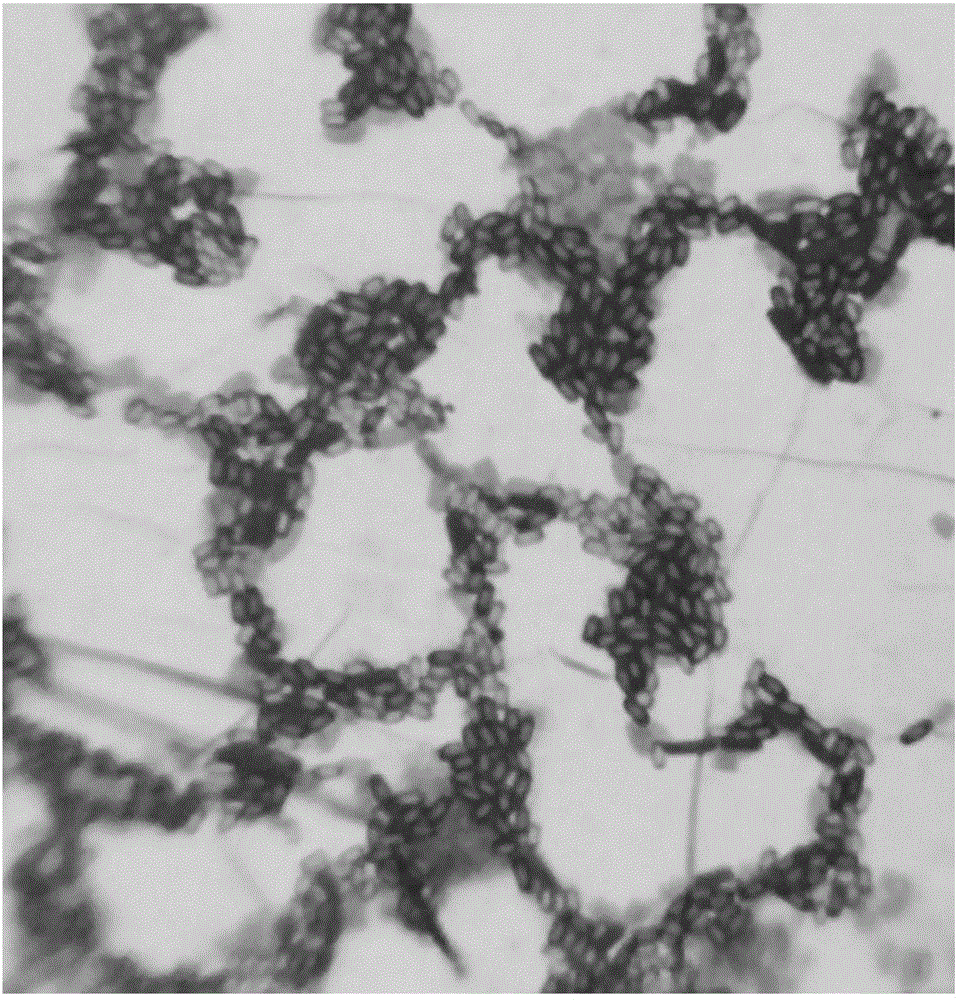

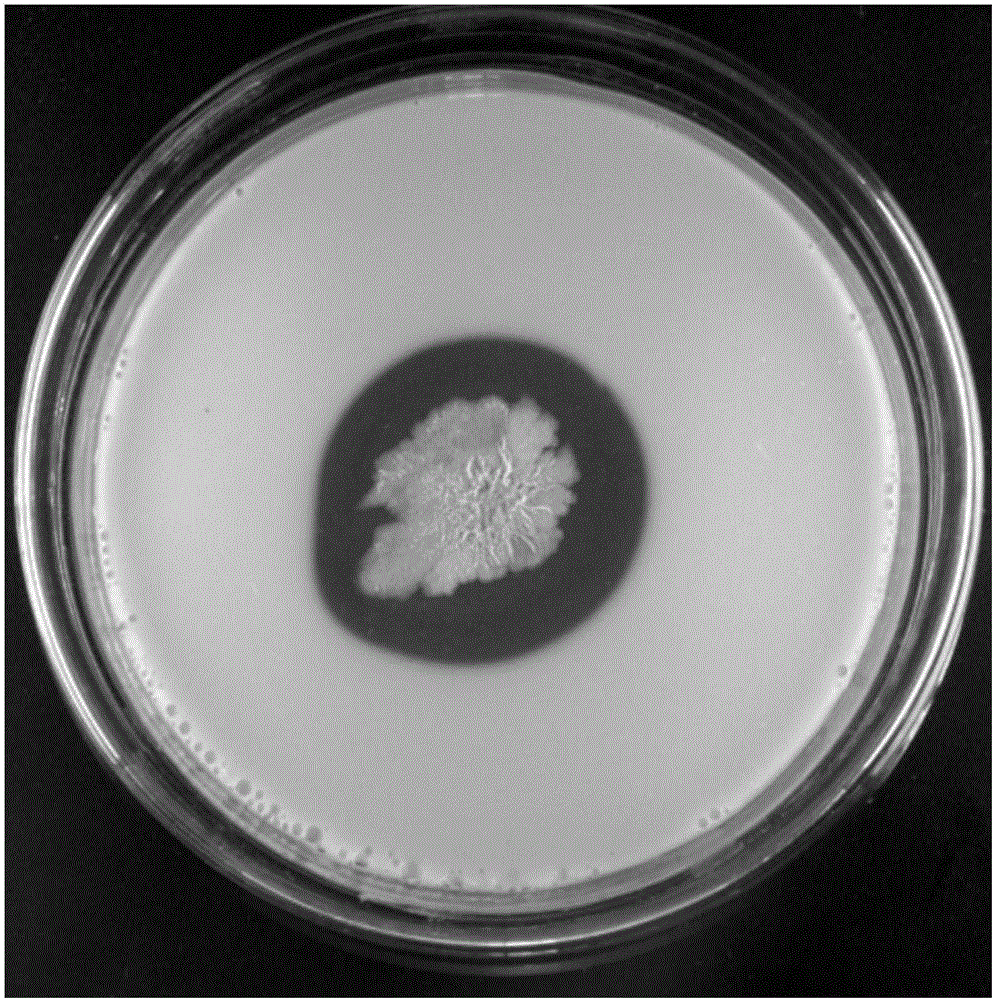

[0035] a. Morphological characteristics: Gram staining is positive, rod-shaped, with spores, and the spores are oval. On LB solid medium, the surface of the colony is rough and wrinkled, opaque, with irregular edges, milky white to slightly yellow;

[0036] b. Physiological an...

Embodiment 2

[0042] Example 2 Preparation of a biological treatment agent containing Bacillus subtilis and its application in kitchen waste

[0043] Preparation of biological treatment agent containing Bacillus subtilis:

[0044] (1) Culture Bacillus subtilis on LB solid culture at 30°C for 24h; inoculate it in a fermentation liquid shaker flask, and culture it with shaking at 30°C and 130r / min for 24h to form a seed liquid;

[0045] The seed liquid is inoculated into the culture material in the fermenter at a volume ratio of 1:400 for fermentation production. The basic working parameters of the fermenter are: temperature: 30-35°C, stirring speed: 130r / min, pH=6.6-7.2 , dissolved oxygen: 30%, tank pressure: 0.04MPa; stop fermentation after 24 hours of fermentation, then centrifuge at 6000r / min for 10 minutes, take the sediment and dilute it with sterile water to make bacterial agent; the concentration of viable bacteria in the bacterial agent is detected to be 6.3 ×10 9 CFU / mL;

[0046]...

Embodiment 3

[0056] Example 3 Preparation of Biological Treatment Agent Containing Bacillus subtilis Inoculum and Application in Kitchen Waste

[0057] This embodiment is basically the same as Example 2, except that in step (2), the mass ratio of sawdust, bran powder and rice husk is 8:1:1; in step (3), microbial inoculum and carrier The mass ratio is 2:15.

[0058] Weight loss efficiency test of biological treatment agent on food waste after treatment:

[0059] (1) The composition of kitchen waste: the food left in the canteen, remove the large and hard parts such as plastic or bones;

[0060] (2) The biological treatment agent prepared by the above method is applied to the treatment of kitchen waste: preheating operation 6h, ventilation and stirring at the same time; 10kg of food waste to be treated is added in the processor after the pre-operation, and biological treatment agent Mix for aerobic fermentation, and ventilate and stir at the same time; the amount of biological treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com