A fungal α-amylase variant with high maltose production rate and preparation method thereof

A high maltose and amylase technology, applied in the field of enzyme engineering, can solve problems such as methods for improving the maltose production rate of fungal alpha-amylase and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

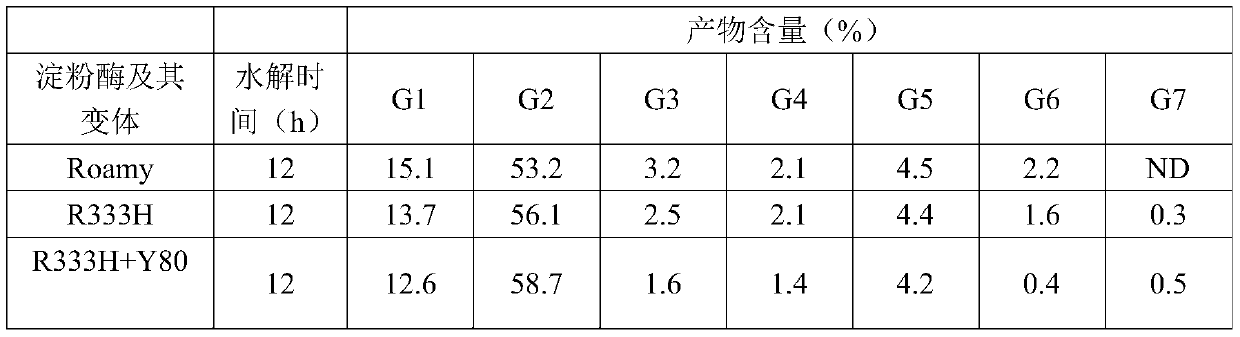

Examples

preparation example Construction

[0087] Preparation of fungal α-amylase variants

[0088] Extract the plasmid DNA in the above-mentioned positive recombinants, use restriction endonucleases EcoRI and NotI to carry out double digestion and connect with the expression plasmid vector pET-28a (+) of the same double digestion, and use the chemical transformation method to The ligation product was introduced into the competent cells of the recipient strain E.coli JM109 to obtain the recombinant plasmid pET-Roamy, which was extracted and introduced into the competent cells of the expression host strain E.coli BL21 to obtain the recombinant plasmid carrying the α-amylase variant coding gene. Recombinant Escherichia coli. The above-mentioned recombinant Escherichia coli is fermented and cultured and induced to express at low temperature to obtain a fermented cell liquid. The cells in the above-mentioned cell liquid were collected by centrifugation and crushed by ultrasonic crushing method. The α-amylase in the cell c...

Embodiment 1

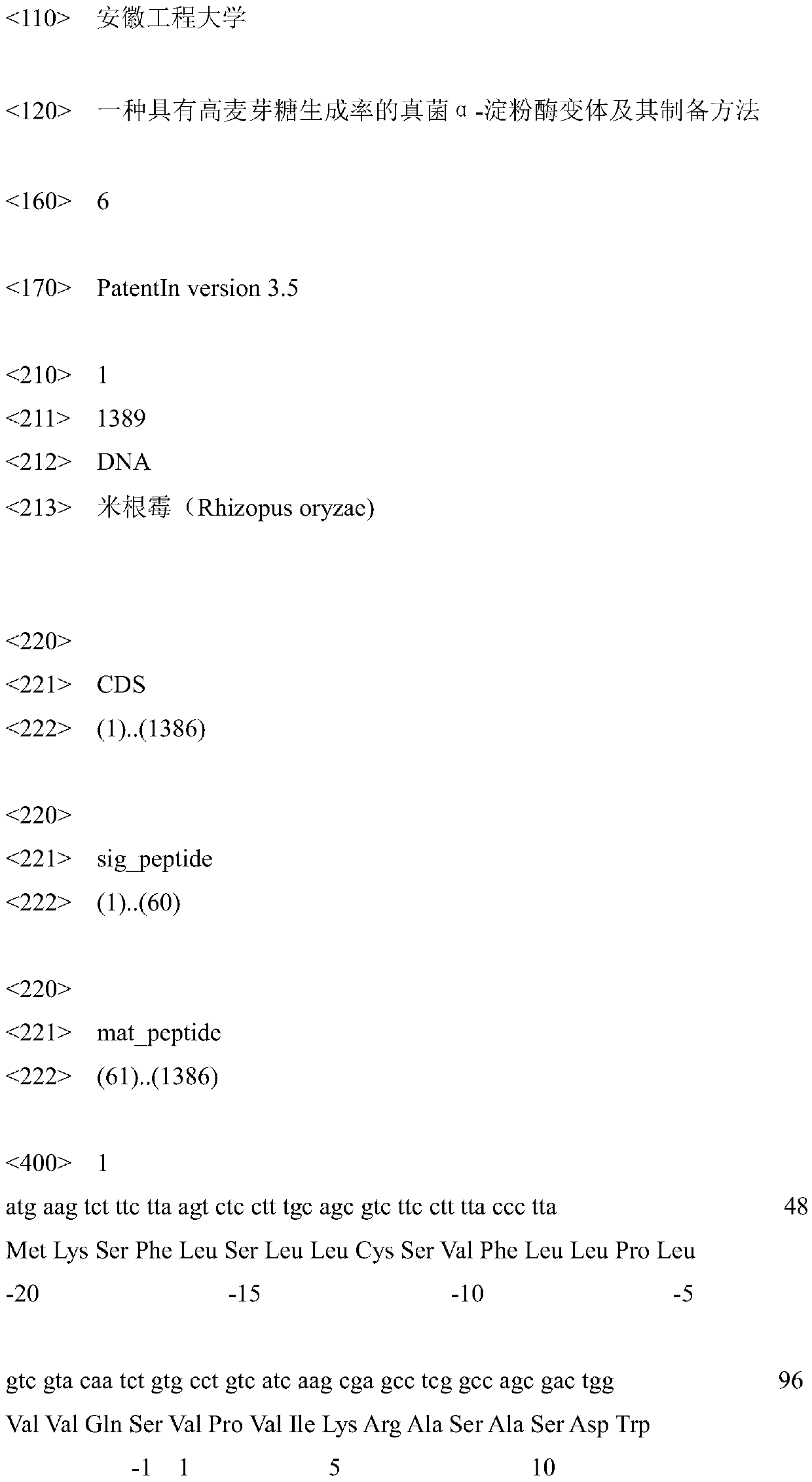

[0091] Cloning of parental fungal α-amylase gene

[0092] Using conventional DNA cloning techniques (Sam Brook J, Fritsch E F. Molecular Cloning Experiment Guide (Second Edition). Jin Dongyan, Li Mengfeng, Hou Yunde, etc. translation. Beijing: Science Press, 1998), extract Rhizopus, Specifically, the total RNA of Rhizopus oryzae F0071 was cloned by reverse transcription technology to obtain the cDNA of the parental α-amylase coding gene, and the cDNA sequence was ligated into the pMD18-simple vector, reacted at 16°C for 4 hours, and then passed the calcium chloride transformation method Introduce E.coli JM109 competent cells, use resistant LB plates to screen positive transformants and obtain recombinant plasmids. The recombinant plasmid was extracted and Sangon Bioengineering (Shanghai) Co., Ltd. was entrusted to complete the sequence determination of the target gene. The sequence of the parent Rhizopus oryzae α-amylase coding gene sequence was determined as SEQ ID NO.1.

[...

Embodiment 2

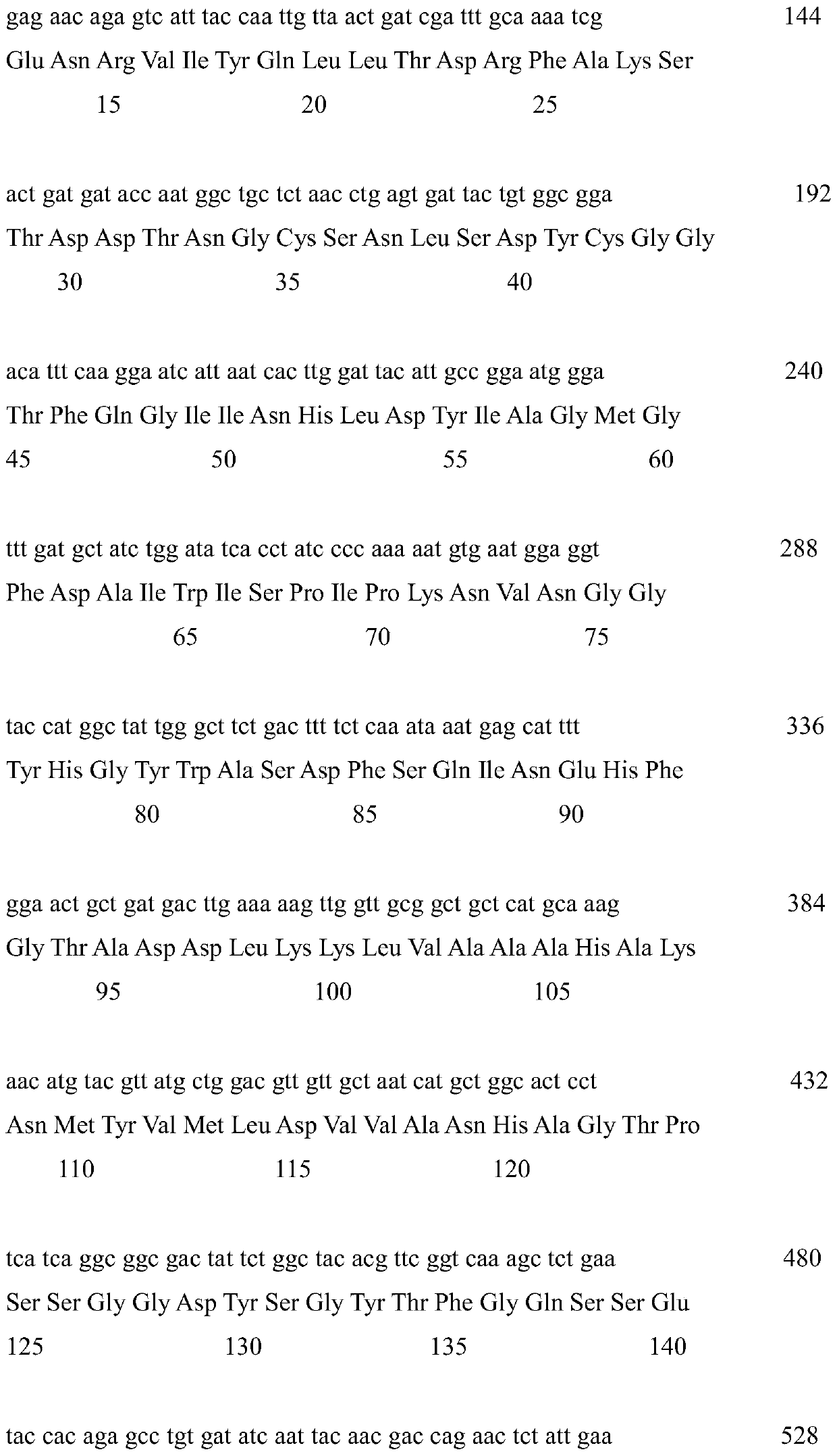

[0095] Construction of variant R333H

[0096] Based on the parent Rhizopus oryzae α-amylase information described in the sequences SEQ ID NO.1 and SEQ ID NO.2, the codon of Y was replaced by the codon of L through primer design, using a commercially available site-directed mutagenesis kit, Mutations were performed according to the instructions provided by the manufacturer (Shanghai Beyond Biotechnology Co., Ltd.) to construct variants of Rhizopus oryzae α-amylase as shown in the sequences SEQ ID NO.1 and SEQ ID NO.2.

[0097] Parent Rhizopus oryzae α-amylase coding gene has been in recombinant plasmid pET-Roamy, with recombinant plasmid pET-Roamy as template, using Pfu DNA polymerase and primer 1 (SEQ ID NO.3) and primer 2 (SEQ ID NO.3) .4) Perform PCR amplification.

[0098] Primer 1: 5ˊ-GTAACGATCCAAACAACCACGAGGTCTTATGGACC-3ˊ

[0099] Primer 2: 5ˊ-GGTCCATAAGACCTCGTGGTTGTTTGGATCGTTAC-3ˊ

[0100] The PCR product was digested with methylase DpnI and then poured into E.coli DH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com