Straw treating method and application thereof

A processing method and technology of straw, which can be applied in application, separation of raw materials, animal feed, etc., can solve the problems of low cellulose and hemicellulose content, unsatisfactory effect of straw, energy loss, etc., and achieve the improvement of crude protein, which is beneficial to Effect of digestion and absorption and reduction of feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The processing of embodiment 1 corn stalks

[0031] A method for processing stalks, comprising the steps of:

[0032] (1) Straw steam explosion pretreatment:

[0033] The crushed corn stalks are kept under pressure of 3.0MPa for 150s, and then the pressure is suddenly released for blasting pretreatment. The processed samples were naturally air-dried for later use;

[0034] (2) Fermentation of corn stalks:

[0035] There were 4 treatment groups in the test, corn stalk group (control group 1), corn stalk + fermented liquid group (control group 2), corn stalk treated by the method disclosed in CN102077903A (control group 3), and the patent blasting corn stalk + fermentation Liquid group (test group), 6 repetitions in each group. They were cultured in a constant temperature incubator at 30°C for 7 days, and samples were taken every 24 hours for determination of relevant indicators.

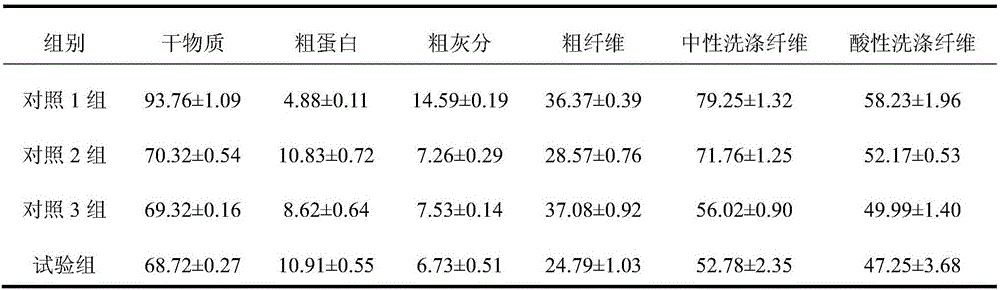

[0036] The physical and chemical indicators of determination include: dry matter, crud...

Embodiment 2

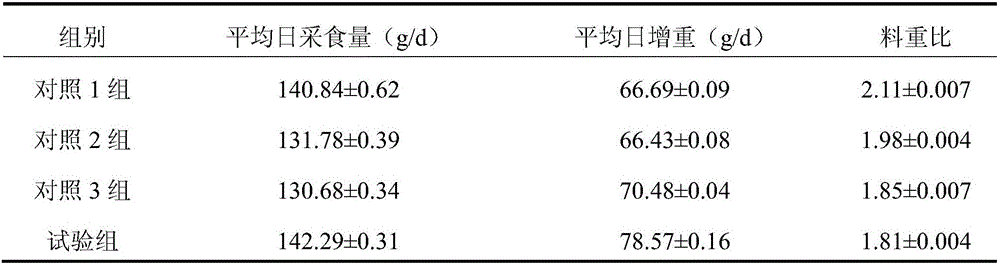

[0040] Embodiment 2 broiler chicken feeding test

[0041] 200 28-day-old broiler chickens were randomly divided into 4 groups, respectively full-price compound feed group (control group 1), corn stalk+fermentation liquid group (control group 2), corn stalks treated by the method disclosed in CN 102077903A (control group 3 groups), the application patent blasting corn stalks+fermentation liquid group (test group), 50 in each group. Control group 1 was fed full-price compound feed, control group 2 used fermented corn stalks instead of 5% full-price compound feed, control group 3 used corn stalks treated with CN 102077903A to replace 5% full-price compound feed, and the test group was fermented with blasting pretreatment Corn stalks were substituted for 5% full-price compound feed, and the test period was 14 days.

[0042] After feeding, the animal production performance indicators are as follows:

[0043] After the test, accurately record the feed consumption, and calculate th...

Embodiment 3

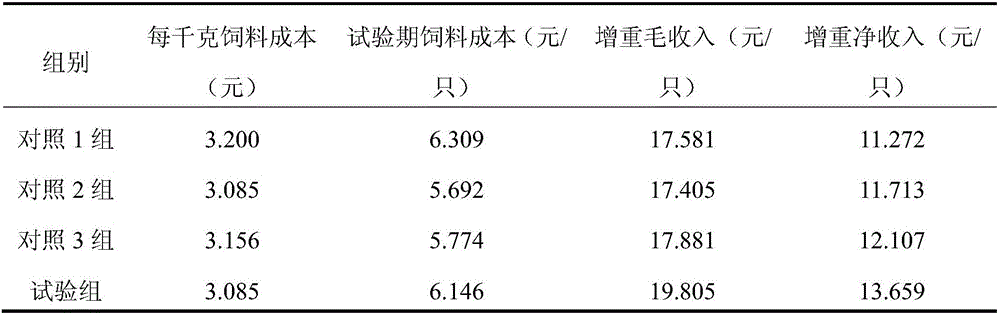

[0056] Embodiment 3 Fat pig feeding test

[0057] A total of 160 healthy and fattening pigs with a weight of about 25 kg were selected and randomly divided into 4 treatment groups, namely the full-price compound feed group (control group 1), corn stalk + fermentation liquid group (control group). 2 groups), corn stalks treated by the method disclosed in CN 102077903A (control group 3), the patented blasting corn stalks+fermentation liquid group (test group), each treatment group had 4 replicates, and each replicate had 10 pigs. Control group 1 was fed full-price compound feed for growing and finishing pigs, control group 2 added 10% fermented corn stalks to the full-price compound feed, and control group 3 added 10% corn stalks treated with CN102077903A to the full-price compound feed. The group added 10% blasting pretreated fermented corn stalks to the full-price compound feed, and the test period was 30 days.

[0058] After feeding, the animal production performance indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com