Flue gas purifying device and circulating fluidized bed boiler with device

A circulating fluidized bed and flue gas purification technology, which is applied to fluidized bed combustion equipment, fuel burned in a molten state, gas treatment, etc., can solve the problems of catalyst loss, denitrification rate, high input and operating costs, etc. Achieve the effects of reducing the difficulty of processing and installation, reducing the power of the blower to induce air, and reducing the amount of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

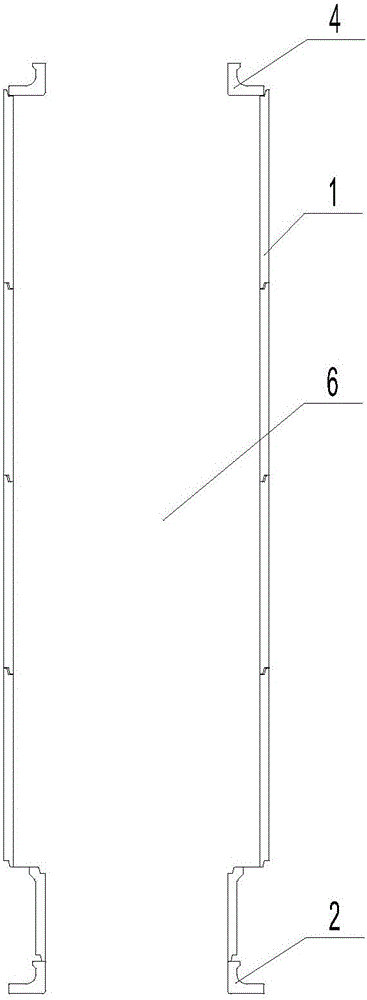

[0025] Embodiment 1: A flue gas purification device, including several pipelines 6 arranged side by side or alternately, the pipeline 6 includes a middle section 1, an inlet section 2, and an outlet section 4, and the inner diameters of the inlet section 2 and the outlet section 4 are smaller than the middle section 1 enclosed inner diameter.

Embodiment 2

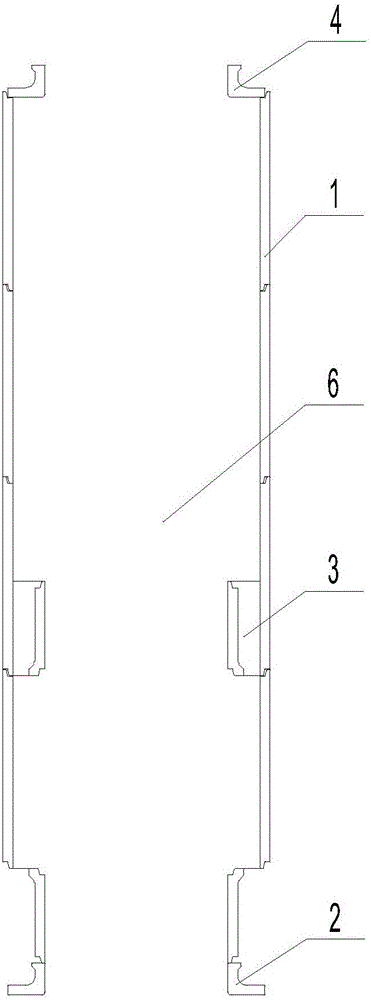

[0026] Embodiment 2: A flue gas purification device, including several pipes 6 arranged side by side or alternately, the pipe 6 includes a middle section 1, an inlet section 2, and an outlet section 4, and the inner diameters of the inlet section 2 and the outlet section 4 are smaller than the middle section Inner diameter enclosed by segment 1. An inner diameter reducing section 3 is provided on the inner wall of the middle section 1 , and the inner diameter enclosed by the inner diameter reducing section 3 is smaller than or equal to the inner diameters of the inlet section 2 and the outlet section 4 . There is one inner diameter narrowing section 3 , which is located in the middle of the middle section 1 near the inlet section 2 . The cross sections of the inlet section 2, the pipe 6, the inner diameter reducing section 3 and the outlet section 4 are circular. The pipeline 6 is a split assembly structure.

Embodiment 3

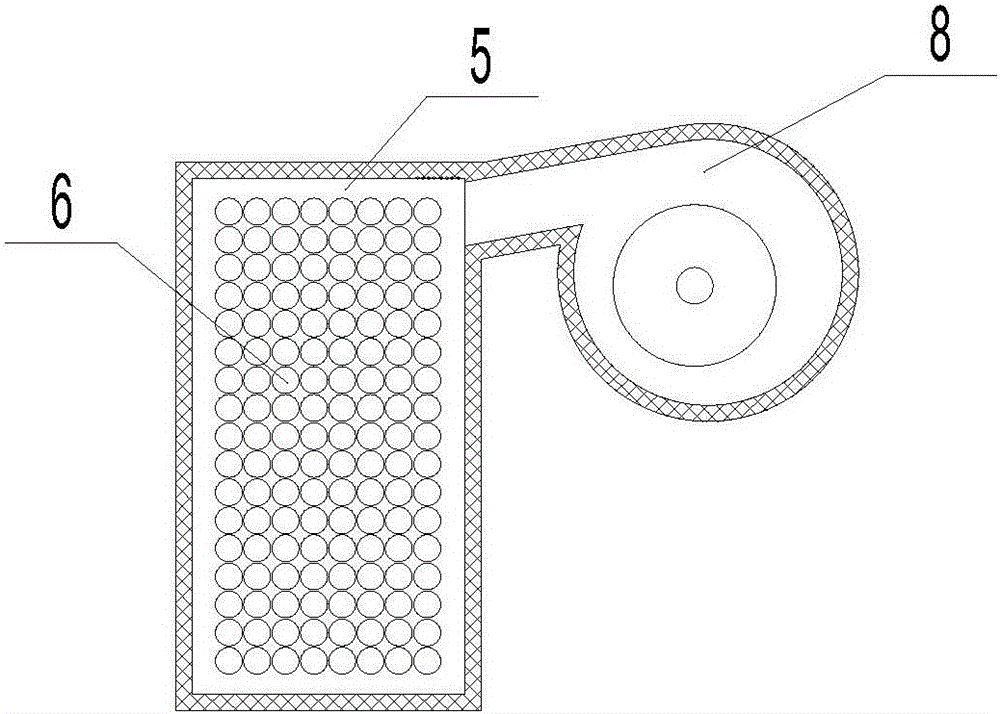

[0027] Embodiment 3: A circulating fluidized bed boiler equipped with a flue gas purification device, including a furnace 7, a separator 8, a feeding device and a heat exchanger, the furnace 7 is connected to the separator 8, and the separator 8 is installed below the Return device, the return device is connected with the furnace 7, the heat exchanger is located at one side of the separator 8 and connected with the separator 8, wherein the air inlet 9 of the furnace 7 is provided with a wind cap 10, and the top of the wind cap 10 is installed with A flue gas purification device, the flue gas purification device includes a number of pipes 6 arranged side by side or alternately, the pipe 6 includes a middle section 1, an inlet section 2, and an outlet section 4, and the inner diameters of the inlet section 2 and the outlet section 4 are smaller than that of the middle section 1 enclosed inner diameter; the refractory material 5 is poured between the adjacent pipes 6 and between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com