Method for purification of taxifolin

A technology of Douglas fir and Douglas fir, which is applied in the field of separation of natural products, can solve problems such as unsuitable for industrial production, complex process, cumbersome steps, etc., and achieve the effects of increasing raw material utilization, accelerating extraction efficiency, and overcoming heavy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

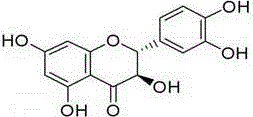

Image

Examples

Embodiment 1

[0020] Take Douglas fir and crush it, weigh 5kg, add 30kg of 40% ethanol solution, ultrasonically extract twice, the ultrasonic frequency is 65KHz, the ultrasonic time is 20min, filter, the filtrate is concentrated under reduced pressure, and the concentrated solution is placed on a D-101 macroporous resin column Adsorption, 3BV water → 4BV70% ethanol elutes the resin column, collects the eluate, concentrates until it has no alcohol smell, and passes through a 3000D hollow fiber polysulfone membrane ultrafiltration, controlling the inlet pressure to 0.25MPa, and the filtrate passes through a 400D hollow fiber Concentrate by nanofiltration of polysulfone membrane, control the inlet pressure to 2.0MPa, and vacuum-dry the concentrate at 75°C to obtain 4.36g of taxifolin with a content of 88.3%.

Embodiment 2

[0022] Take Douglas fir and crush it, weigh 2kg, add 20kg of 50% ethanol solution, ultrasonically extract twice, the ultrasonic frequency is 40KHz, the ultrasonic time is 30min, filter, the filtrate is concentrated under reduced pressure, and the concentrated solution is placed on an AB-8 macroporous resin column Adsorption, 4BV water → 6BV90% ethanol elutes the resin column, collects the eluate, concentrates until it has no alcohol smell, and passes through a 6000D hollow fiber polysulfone membrane ultrafiltration, controlling the inlet pressure to 0.2MPa, and the filtrate passes through a 500D hollow fiber Concentrate by nanofiltration of polysulfone membrane, control the inlet pressure to 1.0MPa, and vacuum-dry the concentrate at 75°C to obtain 2.16g of taxifolin with a content of 89.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com