Method for planting spinaches in artificial light type plant factory

A technology of artificial light and spinach, applied in botanical equipment and methods, fertilization methods, plant cultivation, etc., to achieve the effects of reducing content, good taste, and reducing astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0046] The method for cultivating spinach in a semi-enclosed artificial light plant factory mainly controls the growth and development of spinach by setting different light conditions at different growth stages of spinach, and setting humidity, temperature and fertilization conditions in coordination. The different growth stages of the spinach are divided into three growth stages: seedling stage, vegetative growth stage and harvest stage.

[0047] Light source settings in each growth period: use LED lamps produced by Hunan Pussett Optoelectronics Technology Co., Ltd. as the light source

[0048] Seedling stage: The spectral characteristics of the light source are: the spectrum contains three emission peaks, the first emission peak is located at 580nm, with a relative height of 0.4; the second emission peak is located at 640nm, with a relative height of 1.0; the third emission The peak is located at 710nm, the relative height is 0.1, and the light intensity is 30μmol / (m 2 s), ...

Embodiment example 2

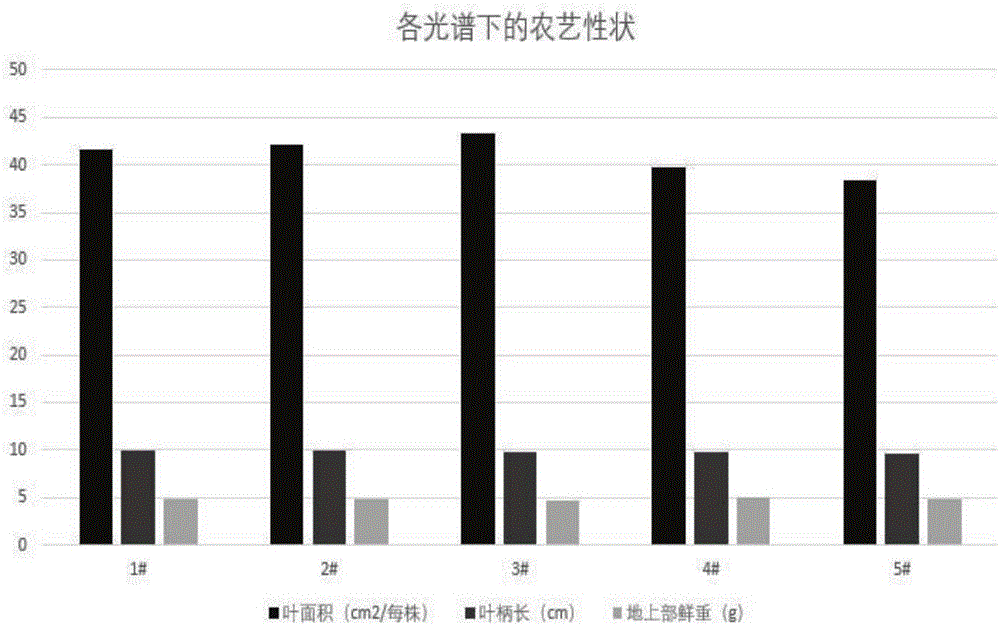

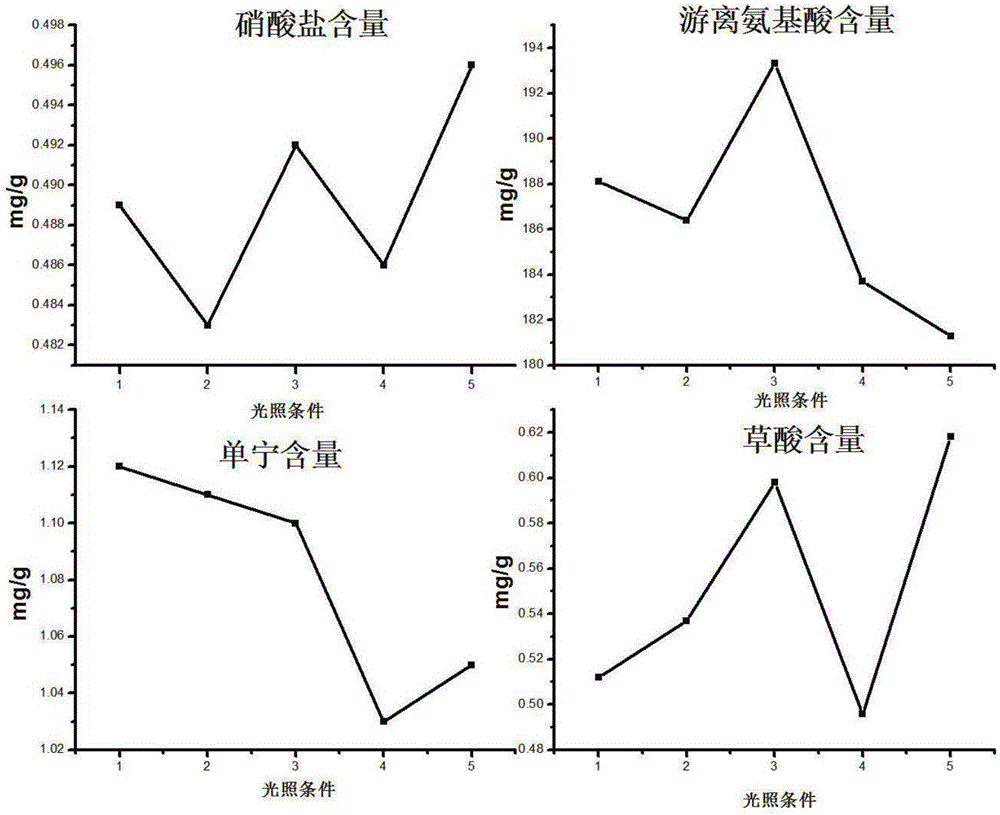

[0053] Taking the light conditions of each stage of the five experimental groups as a single variable, five groups of spinach were cultivated in the plant optics laboratory using the control variable method, and other irrelevant variables were consistent with the implementation case. The light conditions in the five experimental groups are shown in Attached Table 1 , 2, 3, and 4, wherein the fifth experimental group is a control group experiment under natural light conditions (that is, light condition 5 is a control group). The agronomic traits of the products of each experimental group are shown in Attached Table 5, and the contents of other edible functional components in the plants are shown in Attached Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com